Beam plate correcting device for fabricated building

An architectural and prefabricated technology, applied in the construction, building structure, construction material processing and other directions, can solve the problems of excessive weight, offset installation position, limited manpower, etc., to improve assembly efficiency, reduce friction, The effect of improving continuity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

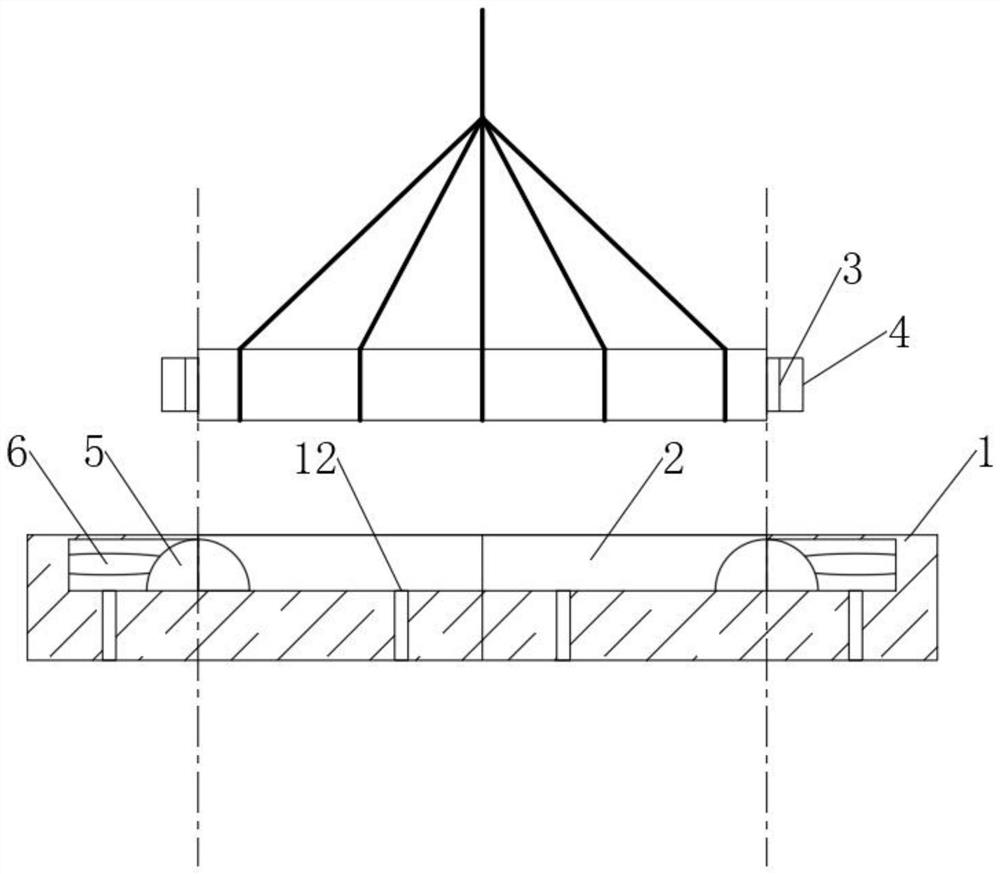

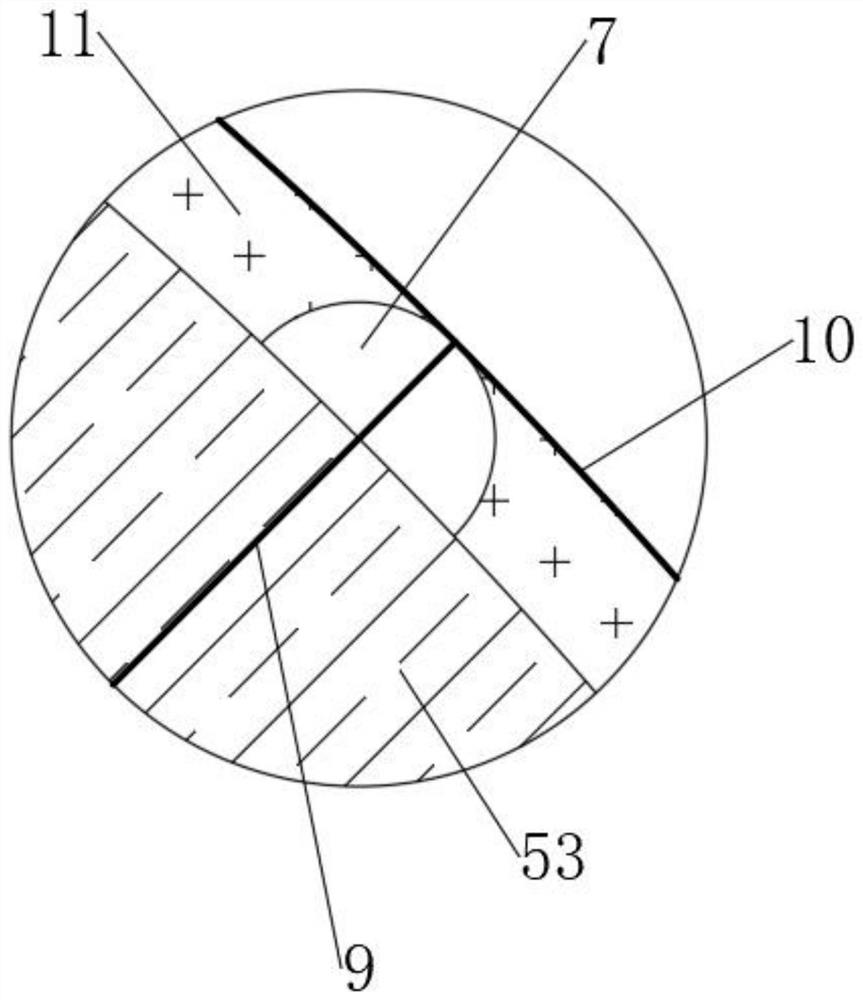

[0041] See figure 1 One assembly building beam coil correction device, including correcting mold 1 and beam plate, and the upper end of the correcting mold 1 is opened with the beam plate phase matching, and there is a avoidance groove on the side wall of the correcting groove 2, the avoidance groove The sliding connection has a phase-matched correction half-pillar 5, and the correction half-column 5 is connected between the side walls of the avoidance groove, and the area of the beam plate corresponds to the regions of the column 5, and the vacuum suction cup 3 is connected to the vacuum suction cup 3. The magnet block 4 is connected, and the magnetogenic coordination is imparted by the specific area of the beam plate, and the vacuum chuck 3 and magnet block 4 can be removed when the initial correction is successfully fallen to the correction mold 1.

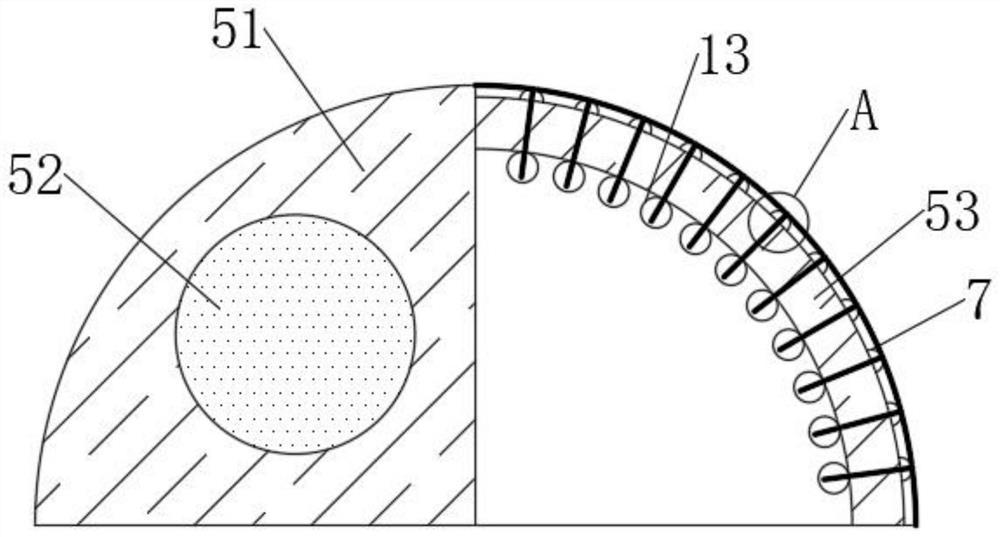

[0042] See figure 2 The corrected semi-column 5 includes a balance post 51, an electromagnet 52, and a correction column 53...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com