Full-automatic deep-fried dough stick preparation system and working method

A preparation system, fully automatic technology, applied in oil/fat baking, baking, dough extruder and other directions, can solve the problems of uneven appearance, not fluffy and crispy fried dough sticks, poor taste, etc., to achieve a fluffy and crisp taste and low cost , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

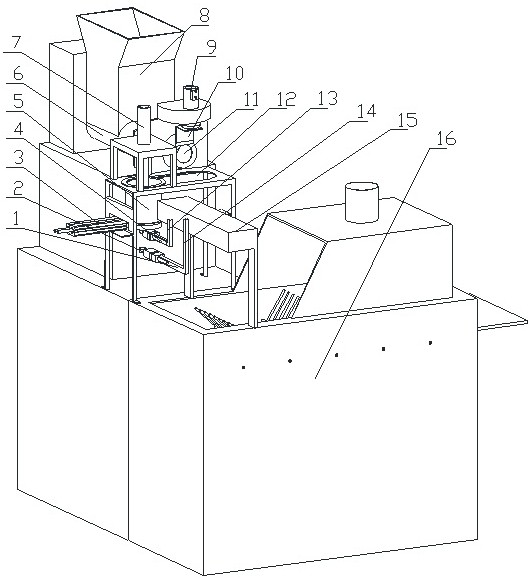

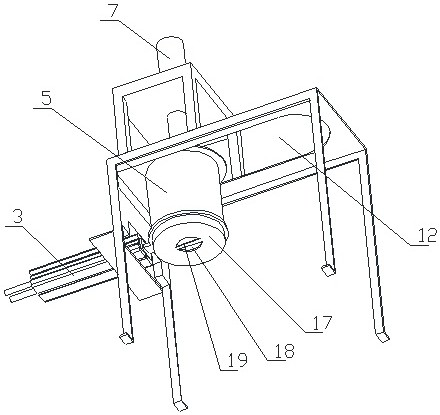

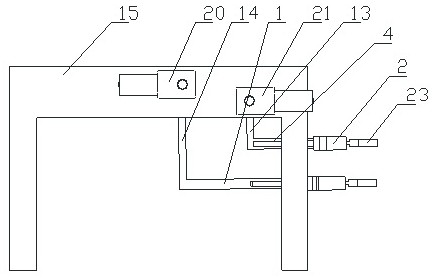

[0021] Such as Figure 1-4 The shown full-automatic deep-fried dough sticks preparation system comprises a noodle base supply device and a deep-fried dough stick frying pot 16. The pot can automatically output the cooked fried dough sticks. Described dough supply device comprises the dough extruding device and the dough shaping device that are arranged on the support frame, and the dough extruding device comprises the single-pipe screw conveyer 6 that left and right directions are arranged, and the single-pipe screw conveyer 6 A noodle storage bucket 8 is provided on the feed inlet. The outlet 11 of the single-pipe screw conveyor 6 is located at its right-hand side, and the support frame above the outlet 11 of the single-tube screw conveyor 6 is provided with a cutting cylinder 9, and the piston rod of the cutting cylinder 9 is installed with a single-pipe screw conveyor. The noodle cutter 10 that can be moved up and down to be cut by the noodle outlet 11 of 6 is matched; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com