SCR low-temperature denitration device

A low-temperature denitrification and catalyst technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, can solve the problems of catalyst agglomeration deactivation, low catalytic efficiency, and insufficient cooling effect of adsorption to extend the reaction time. , the effect of improving the catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

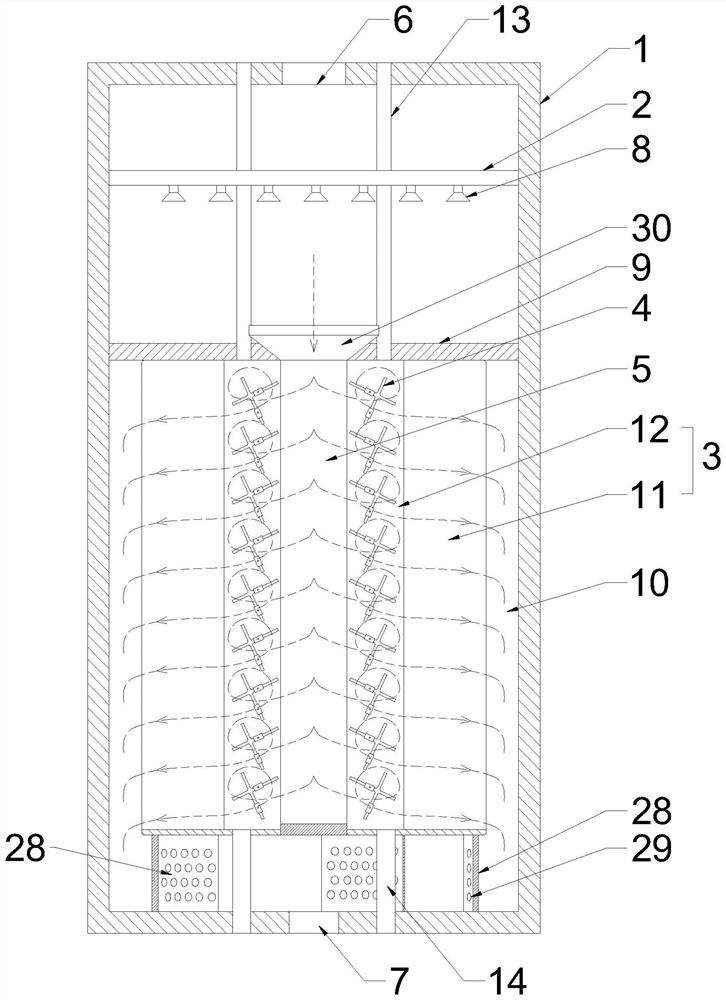

[0031] Such as Figure 1 to 4 As shown, a SCR low temperature denitration apparatus includes a reactor housing 1, a spray gate 2, a catalyst reservoir 3, a tip fixture 4, and an inner tube 5. The top of the reactor housing 1 has a flue gas inlet 6, and the bottom is provided with a flue gas outlet 7, and the desulfurization is low-temperature smoke (170-250 ° C) is injected into the reactor housing 1 in the reactor housing 1 by the flue gas inlet 6.

[0032] The spray head 8 of the via the ammonia line is mounted on the spray gate 2, and the sprayed head 8 is sprayed with a gasification, which contains NO. X Flue gas denitration, the primary product after the reaction is n 2 Ho 2 O, remove the reactor housing 1 by the flue gas outlet 7 after removing the ammonium salt, dust such as a catalyst reservoir.

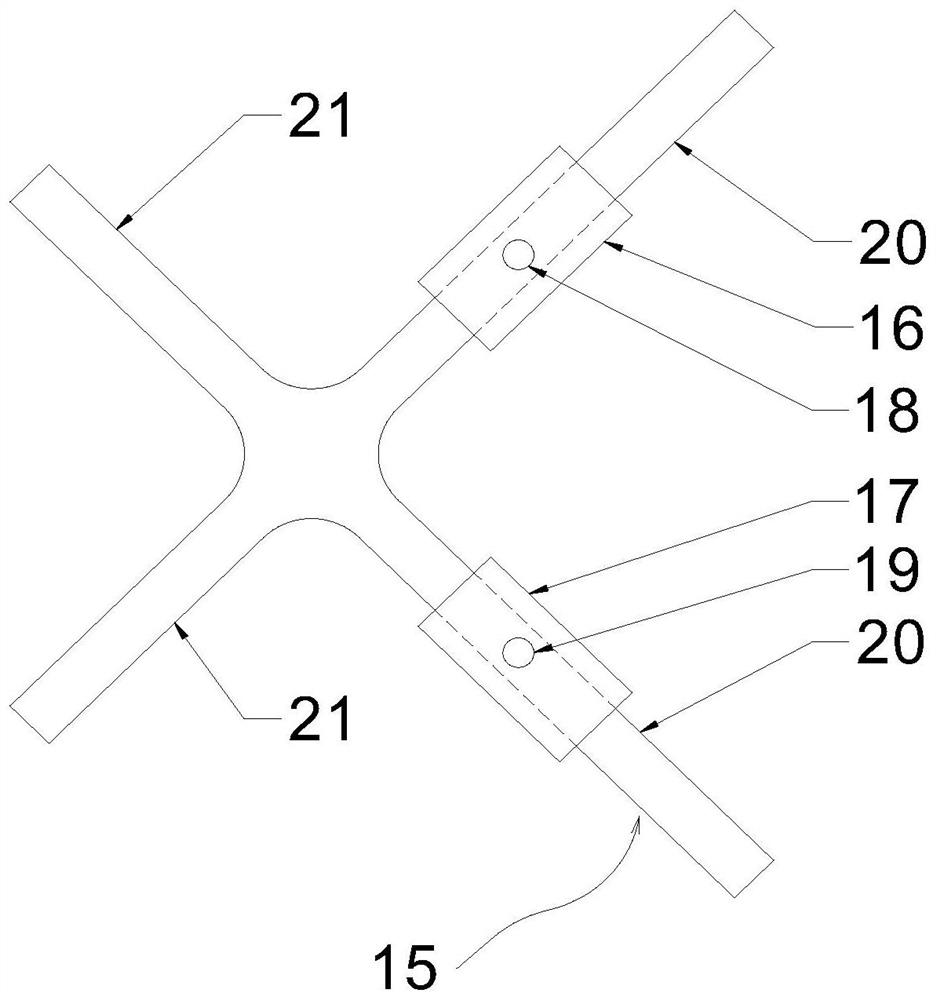

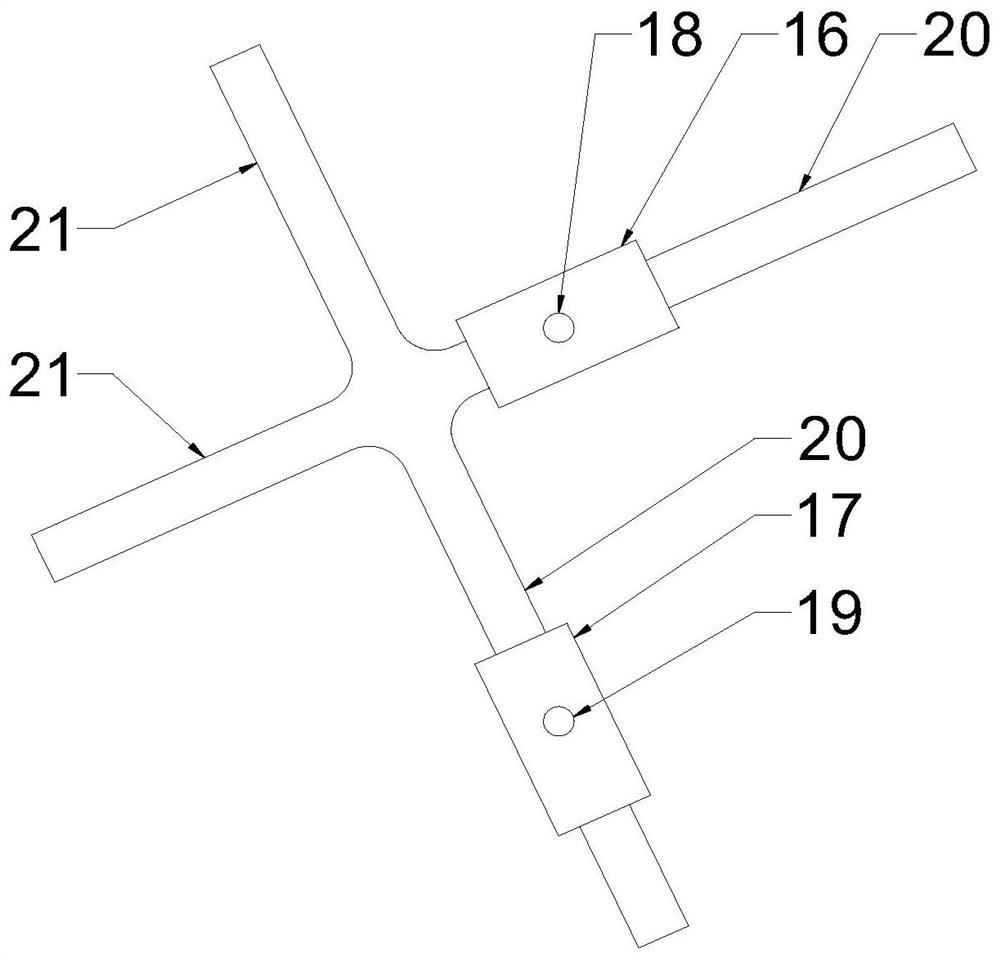

[0033] The catalyst cartridge 3 is fixed to the reactor housing 1 and below the spray ammonagner 2, and the top portion of the catalyst reservoir 3 is fixedly mounted, and the ba...

Embodiment 2

[0049] Such as Figure 5 As shown, the difference from the present embodiment and the first embodiment is that the base structure is different. The base of the present embodiment includes a plurality of arcuate guiding plates 32, and the guide plate 32 is arranged along the screw trajectory, and the spiral trajectory The airflow flowing between the adjacent fluid plates 32, the air flow flowing out of the flue gas overflow passage 10 is quickly flowing into the flue gas outlet 7 along the spiral trajectory after the engaging air gap 33, and then pumped into the chimney by the air blower. Among them, a plurality of vent holes 29 are also provided on the outermost circular fluid plate, which facilitates the quick flow of 10 in the flue gas overflow passage to enter the spiral trajectory of the vent hole 29 into the inner ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com