Device and construction method for positioning and correcting first-layer steel structure column

A steel structure and column positioning technology, which is applied in the direction of basic structure engineering, columns, pier columns, etc., can solve problems such as difficult technology and complicated process, and achieve significant economic benefits, convenient operation, simple and labor-saving positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

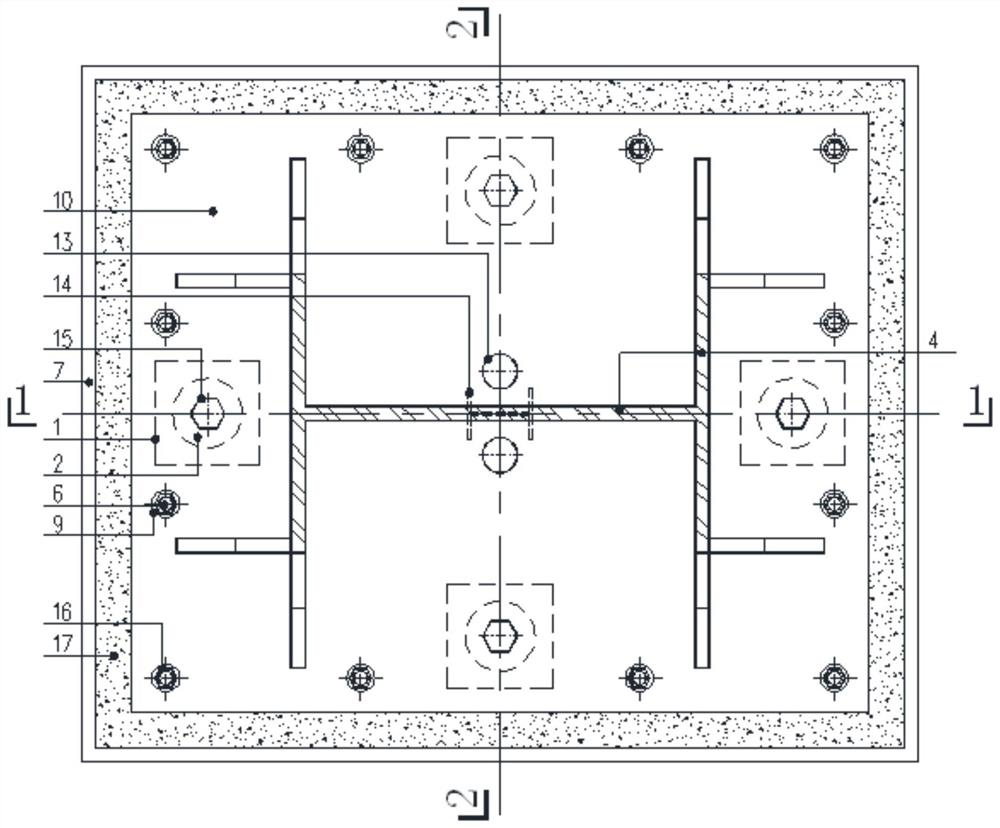

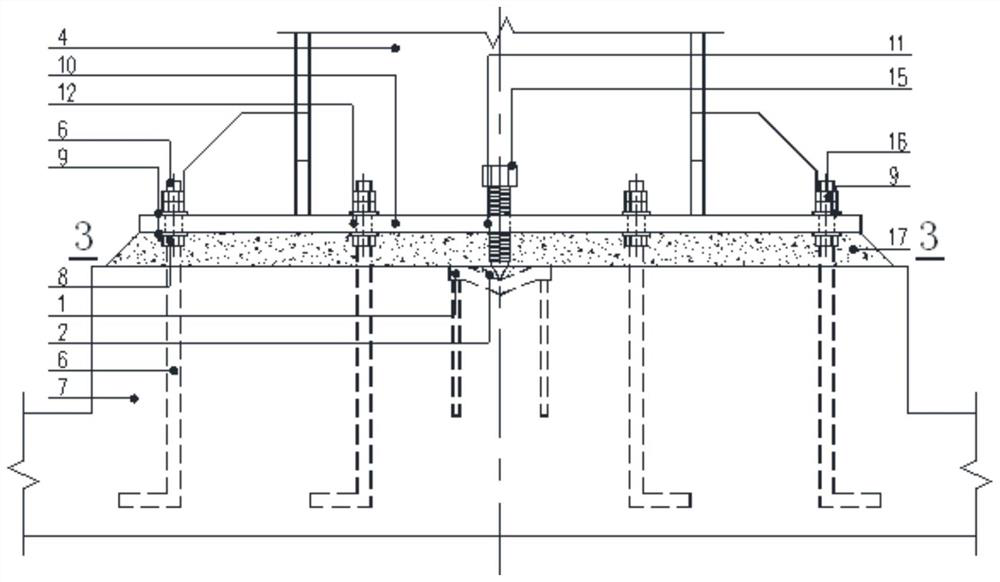

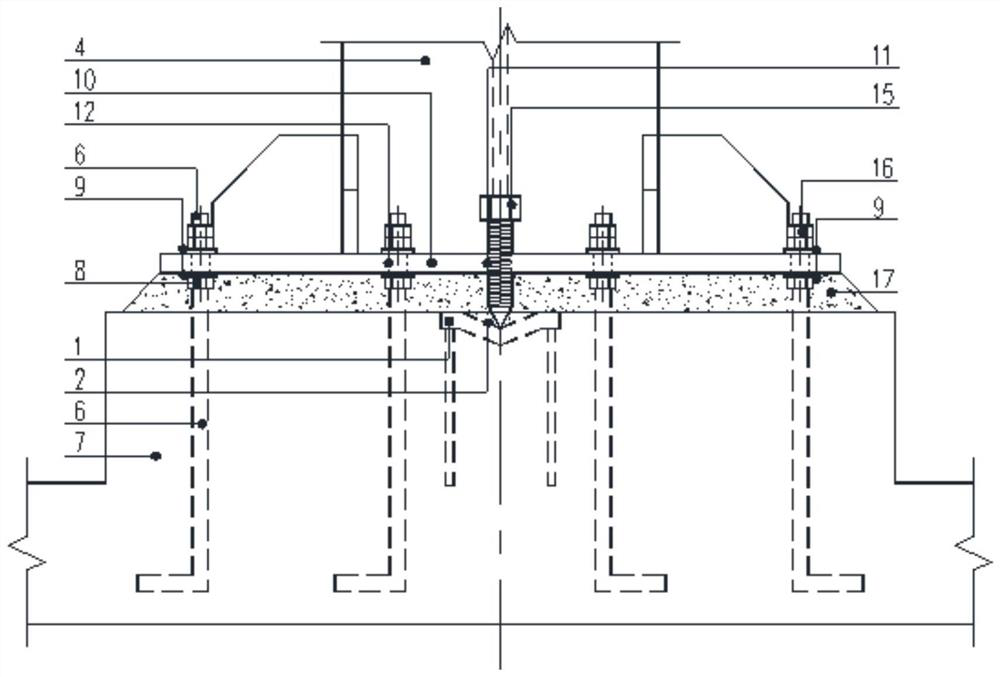

[0039] A positioning and correcting device for steel structure columns on the first floor, such as figure 1 As shown in -5, the installation structure of the steel structure column positioning and correction device on the first floor consists of three basic components: the column bottom end plate 10, the conical head positioning screw 15 and the foundation positioning embedded part 1. The foundation positioning embedment is set at the part of the foundation to be installed, and the foundation positioning embedment is provided with a tapered groove and a positioning marking line with a guiding positioning function, and the upper surface of the foundation installation part is provided with a shear groove and a pre-embedded column foot fixing bolt; The end plate at the bottom of the column is set at the bottom of the steel structure column body on the first floor, and the end plate at the bottom of the column is provided with positioning screw holes, mounting and fixing holes and ...

Embodiment 2

[0049] The construction method of the positioning and correcting device for the steel structure column on the first floor includes the following steps:

[0050] Pre-embedding of foundation positioning embedded parts → fabrication and installation of column bottom and end plates → hoisting of steel structure column body → correction and connection of steel structure column → pouring, maintenance and removal of temporary support in the space under the column.

[0051] ①. Pre-embedded construction of foundation positioning embedded parts

[0052] The base positioning embedded part 1 is provided with a tapered groove 2 and a positioning marking line 3 with guiding and positioning functions, and the intersection point of the longitudinal and horizontal positioning marking lines 3 is located on the vertical center line of the tapered groove 2; Line and the plane central axis of the steel structure column body 4; according to the position and elevation of the foundation positioning e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com