Drying equipment for large-aperture quarrying expanding agent production

A technology of quarry expansion agent and drying equipment, which is applied in drying, dryer, lighting and heating equipment, etc., can solve the problem of uneven drying of quarry expansion agent, inability to guarantee the degree of drying, and cumbersome discharge. and other problems to achieve the effect of avoiding insufficient drying, convenient feeding and discharging, and uniform drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

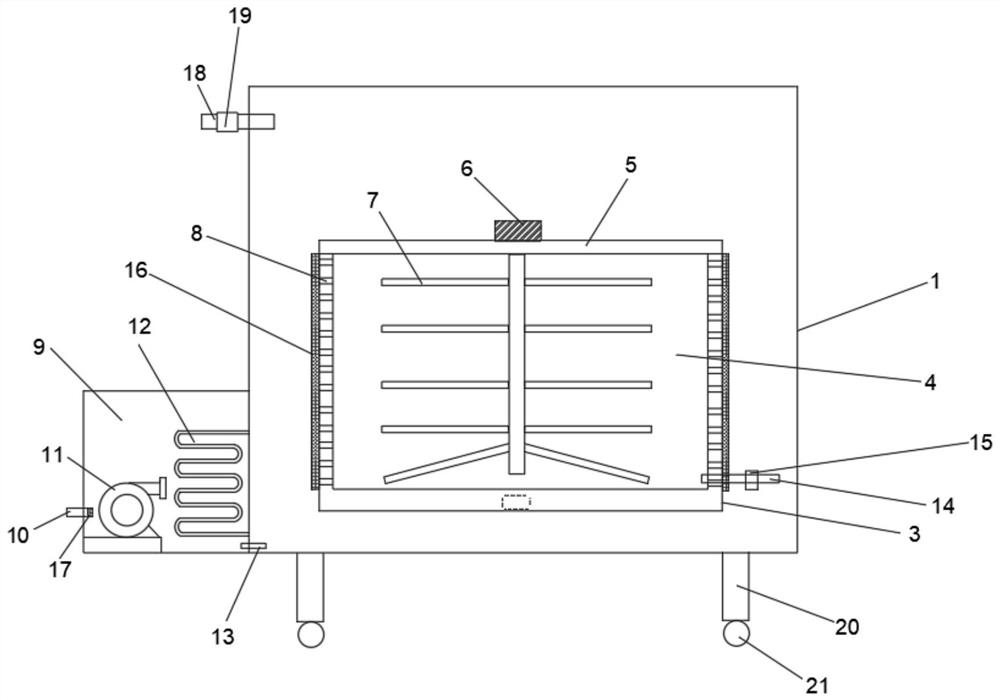

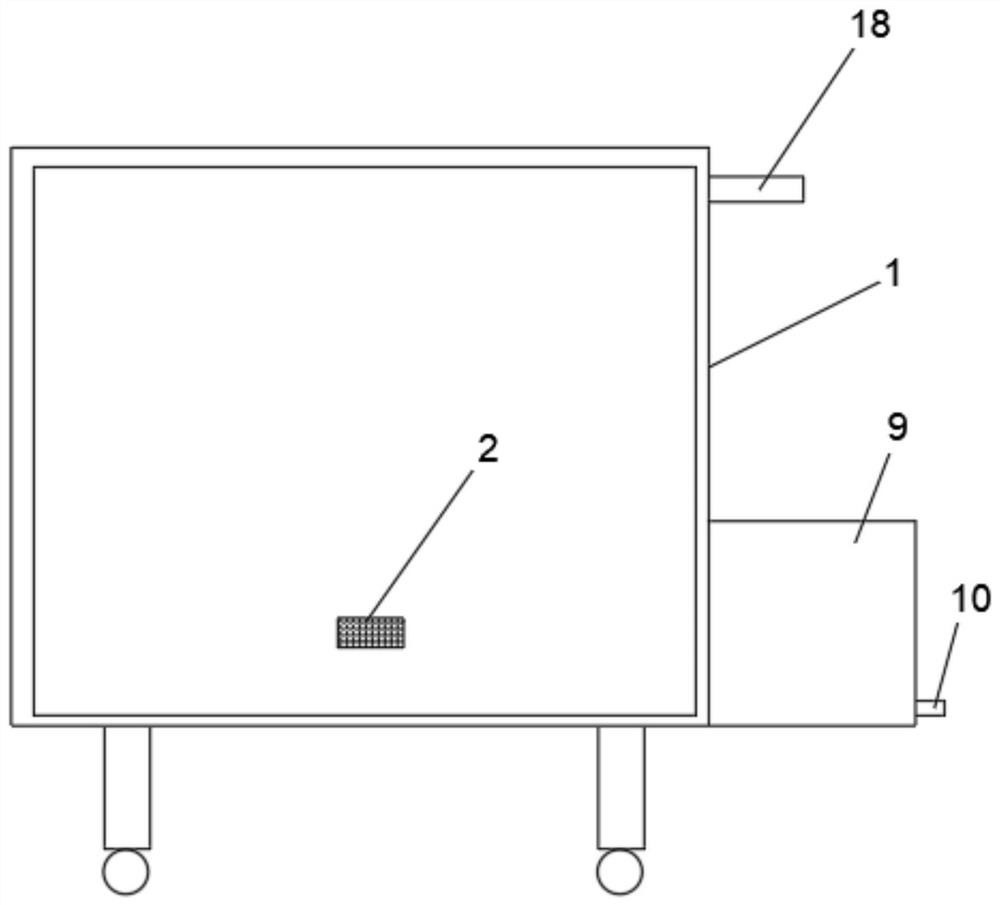

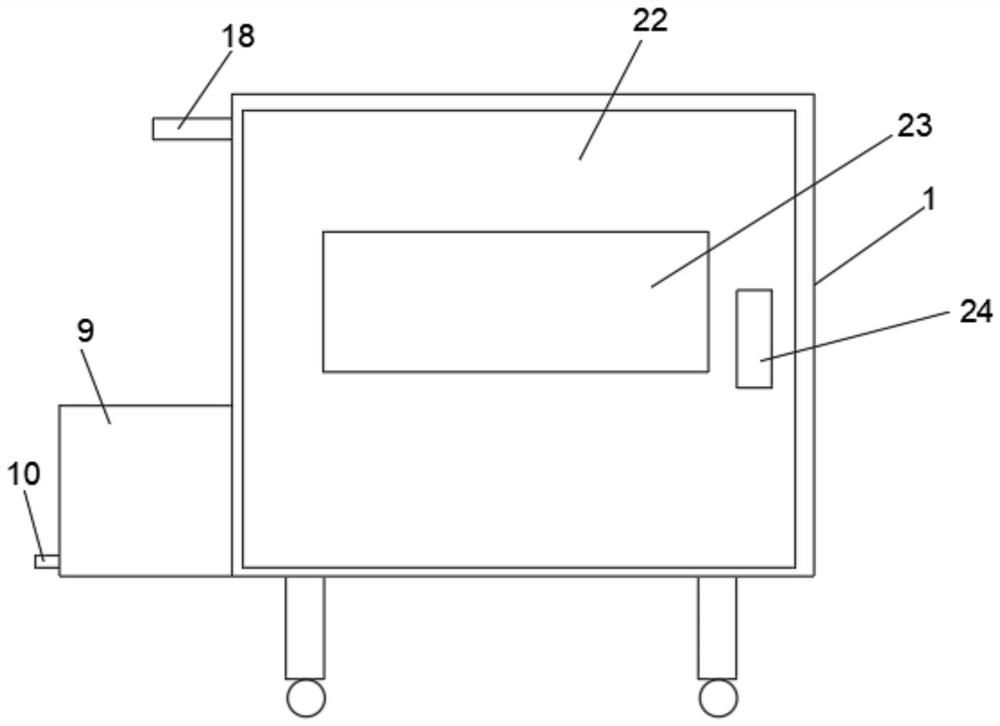

[0022] like Figure 1-Figure 3 As shown, the present invention provides a kind of drying equipment for large-aperture quarrying expansion agent production,

[0023] Including a drying box 1, the rear wall of the drying box 1 is provided with a cylinder 2, the output shaft of the cylinder 2 extends through the rear wall of the drying box 1 into the drying box 1, and is located in the The output shaft of the cylinder 2 in the drying box 1 is provided with a placement box 3, and the placement box 3 is provided with a cavity 4 for the insertion of a large-diameter quarrying expansion agent, and the upper end of the placement box 3 is hingedly provided with a top cover 5. The top cover 5 is provided with a motor 6, the output shaft of the motor 6 extends through the side wall of the top cover 5 into the storage box 3, and the output shaft of the motor 6 is located in the storage box 3 A stirring shaft is arranged on the top, and a stirring blade 7 is arranged on the stirring shaft...

Embodiment 2

[0032] like Figure 1-Figure 3 As shown, this embodiment is a further optimization made on the basis of embodiment 1. Specifically, the surfaces of the motor 6 and the cylinder 2 are provided with a heat dissipation layer, and the heat dissipation layer adopts a heat-conducting polyester paint layer.

[0033] In this embodiment, a heat dissipation layer is arranged on the surfaces of the motor 6 and the cylinder 2. The heat dissipation layer adopts a heat-conducting polyester paint layer. The heat dissipation layer can improve the heat dissipation performance of the motor 6 and the cylinder 2. When the motor 6 and the cylinder 2 work, It can play the function of auxiliary heat dissipation, avoid overheating of the motor 6 and the cylinder 2, reduce the failure rate of the motor 6 and the cylinder 2, and improve the safety performance of the motor 6 and the cylinder 2 when in use.

Embodiment 3

[0035] like Figure 1-Figure 3 As shown, this embodiment is a further optimization made on the basis of Embodiment 2. Specifically, the lower end of the drying box 1 is provided with a fixed shaft 20, and the lower end of the fixed shaft 20 is provided with a pulley 21, so Brake pads are arranged on the pulley 21.

[0036] In this embodiment, fixed shaft 20 and pulley 21 are arranged at the lower end of drying box 1, which facilitates the movement and maintenance of the present invention, improves the flexibility of the present invention, and reduces the work intensity of operators. By setting brake pads on pulley 21, It plays the role of fixing the drying box 1, preventing its operation process from sliding, causing collision with other equipment or operators, and causing losses.

[0037] working principle

[0038] The present invention is a drying equipment for the production of large-aperture quarrying expansion agent, and the distribution of each part is as follows: Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com