Transformer manufacturing and processing technology

A processing technology and transformer technology, applied in the field of transformer manufacturing, can solve problems such as low efficiency, easy errors in measurement tools, and low quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

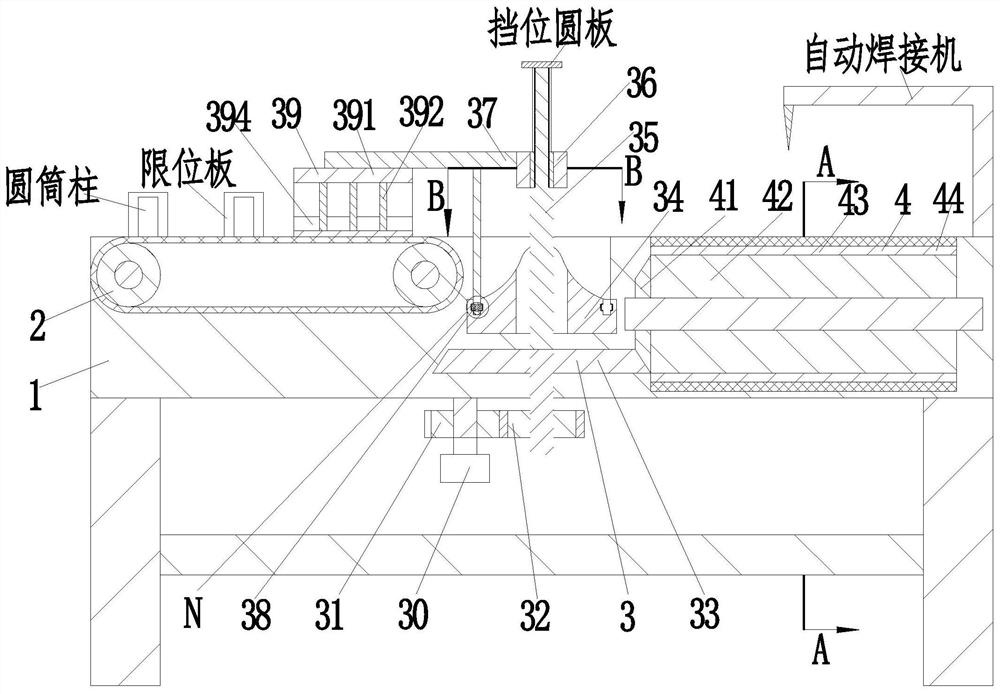

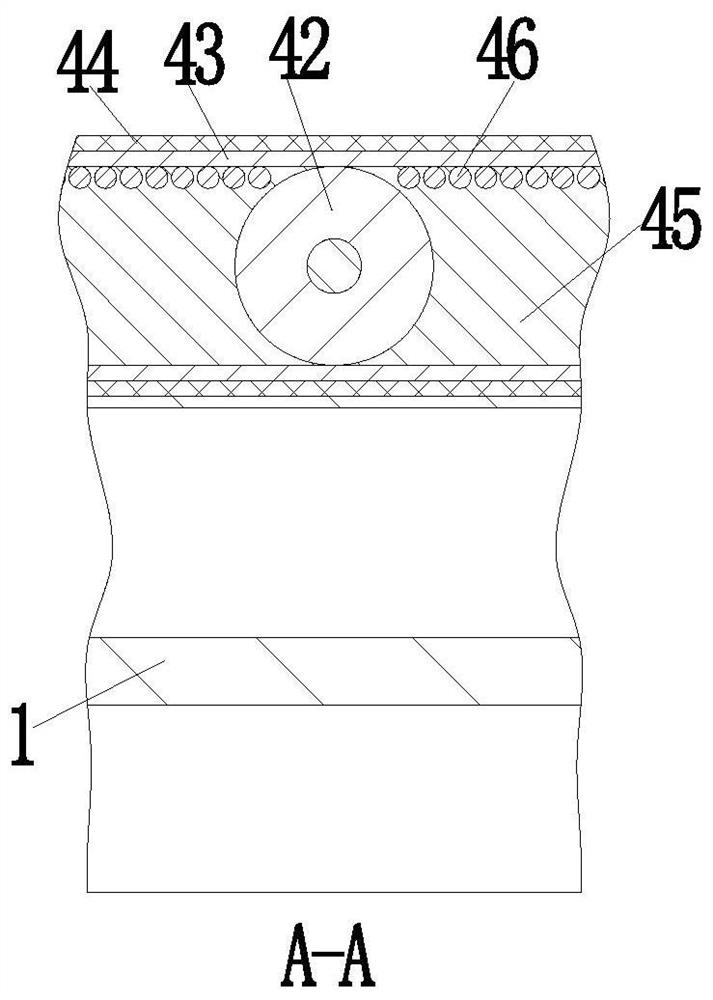

[0037] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

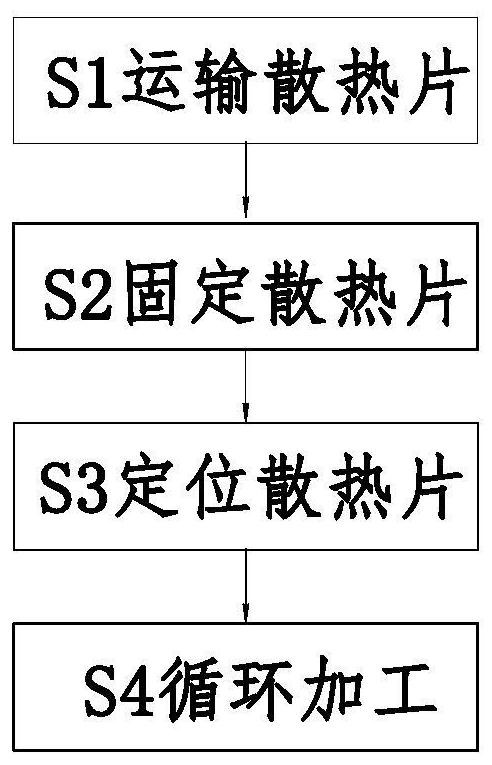

[0038] A transformer manufacturing and processing technology, which uses a transformer manufacturing and processing equipment, the transformer manufacturing and processing equipment includes a workbench 1, a belt conveyor 2, a positioning device 3 and a transport device 4, the transformer is processed by the above transformer manufacturing and processing equipment The specific method of manufacturing and processing is as follows:

[0039] S1. Transporting the cooling fins: transporting the cooling fins through the belt conveyor 2;

[0040] S2. Fixing the heat sink: fix the heat sink through the positioning device 3, and transport it to the right at the same time;

[0041] S3. Positioning the heat sink: through the cooperation of the positioning de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com