Electric appliance element sealing structure and clothes treatment device applying same

A technology for clothes processing devices and electrical components, which is applied in the direction of electrical components, applications, washing devices, etc., which can solve the problems of inability to achieve airtightness, unclear glue sizing path and dosage at seams, and easy detachment, so as to increase the capacity of electrical appliances The space of components, ensuring the consistency and stability of mass production, and the effect of increasing the bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

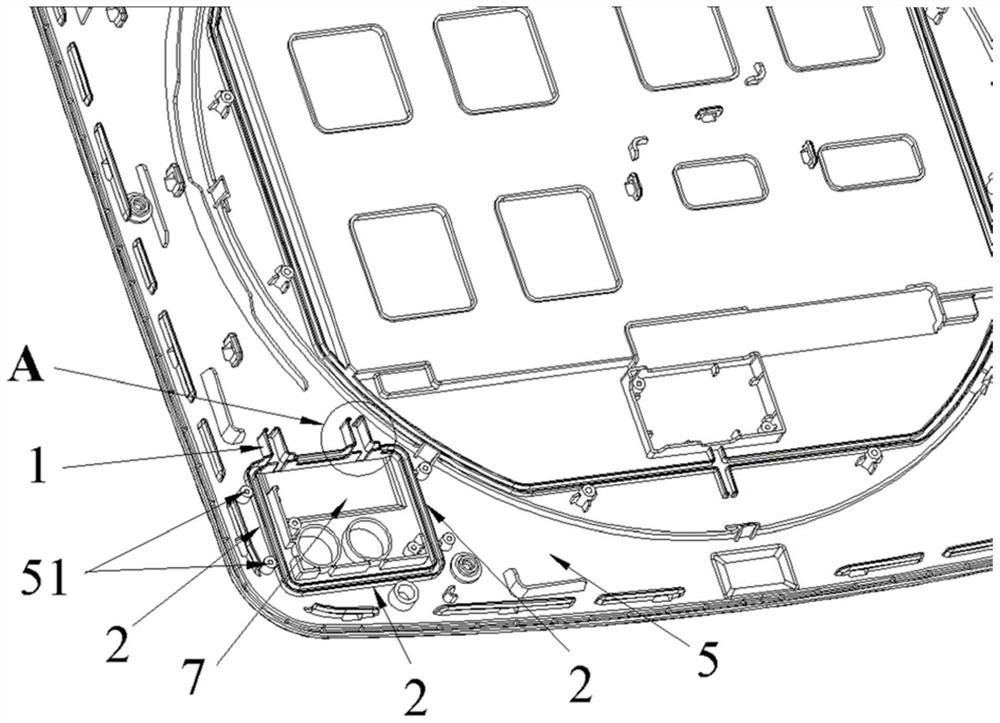

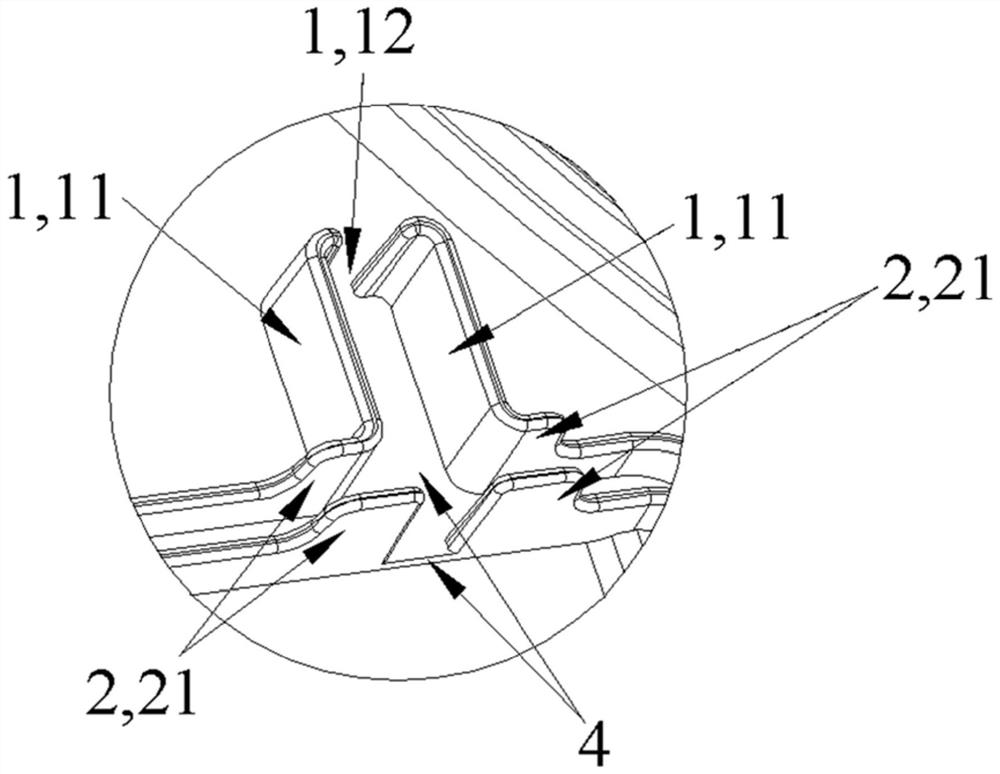

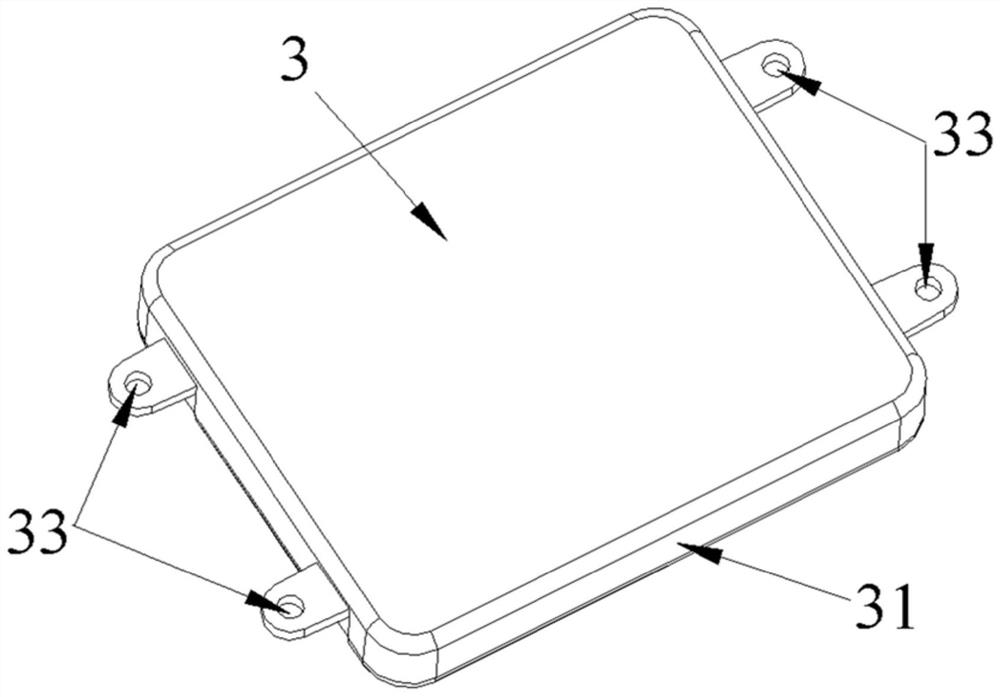

[0051] In this example, if figure 1 As shown, a sealing structure for electrical components is provided, including: an installation body 5, which is provided with a glue filling groove 2 surrounding the electrical components; a sealing cover 3, which is sealed and buckled with the glue filling groove 2; the glue filling groove One side of 2 extends outwards and is provided with a wire passing groove 1 communicating with the glue filling groove 2, and the wire passing groove 1 is used for passing the wires 6 of electrical components.

[0052] In this embodiment, potting glue is often used for bonding, sealing and coating protection of electronic components. The potting glue used is in a liquid state before it is cured and has a certain fluidity. After it is completely cured, it can play a role Waterproof, dustproof, insulation, heat conduction, sealing, anticorrosion, heat resistance, shockproof and other functions. In the present invention, in order to make the potting glue p...

Embodiment 2

[0070] The difference between this embodiment and embodiment 1 is:

[0071] In this embodiment, the extension end of the wire passing groove 1 is clamped with the wire 6 of the electrical component, and the intersection of the wire passing groove 1 and the glue filling tank 2 is provided with a clamping connection with the wire 6 of the electrical component. Snap-in structure (not shown in the attached drawings).

[0072] In this embodiment, due to the long length of the wire trough, in order to ensure that the wires in the middle will not bulge due to bending, a structure for clamping the wires can be provided at the position where the glue potting groove communicates with the wire trough, for example, a wire clip The claws located at the bottom of the wire trough.

[0073] In this embodiment, in the specific processing process, in order to achieve a better glue filling effect, the width of the glue filling groove can be widened near the wire groove (due to the widening of t...

Embodiment 3

[0078] In this embodiment, a clothes processing device is provided, the clothes processing device adopts an operation interface including touch buttons and a touch screen, and the control panel has a built-in computer board for the touch screen and touch buttons with relatively complicated wiring and the button element, the clothes treatment device uses the sealing structure as described in Embodiment 1 or 2 to seal the button element arranged on the installation main body 5 . The clothes processing device is selected from one of a washing machine, a clothes dryer, and an integrated washing and drying machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com