A kind of preparation method of gelatin modified starch type sizing agent

A starch-type sizing agent and a modification technology are applied in the field of preparation of gelatin-modified starch-type sizing agents, which can solve the problems of high cost, complicated preparation process, poor stability, etc., and achieve low cost, simple preparation process, and easy film formation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

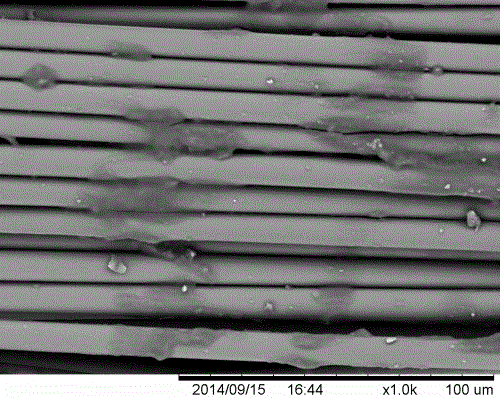

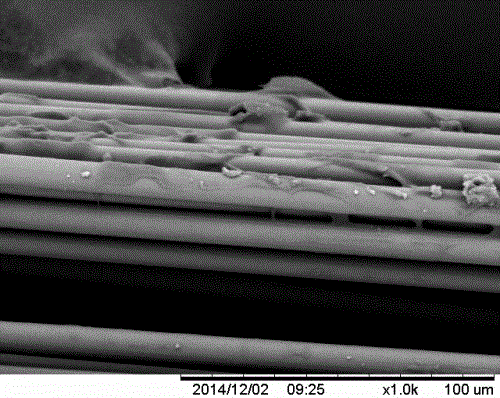

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] A kind of preparation method of gelatin modified starch type sizing agent, it is characterized in that comprising the following steps:

[0024] (1) Pretreatment: use starch as raw material, dry at 50°C for 24 hours, pass through an 80-mesh sieve, take 15 parts by mass of the original starch for removal of impurities, mix 2 parts by mass of gelatin with 400 parts by mass of aqueous solution, and dry at 90°C React for 1 hour to obtain a modified starch paste solution;

[0025] (2) Ingredients mixing: in the modified starch paste solution, slowly add 0.25 parts by mass of glutaraldehyde solution, 0.5 parts by mass of glycerol, 0.25 parts by mass of polyvinyl alcohol, 0.5 parts by mass of glutaraldehyde solution, The sodium sulfate of mass part, the Tween 60 of 0.3 mass part, obtains mixed material;

[0026] (3) Reaction: Stir the mixture at 90° C. for 2 hours to obtain a reaction mixture; cool the reaction mixture to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com