Resin coated holder for roller bearings

A technology for rolling bearings and cages, applied in the direction of roller bearings, bearing components, shafts and bearings, etc., can solve the problems of not being able to fully improve the mechanical strength of cages, and cannot use resin cages, so as to improve mechanical strength and durability , Strong tensile capacity, strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

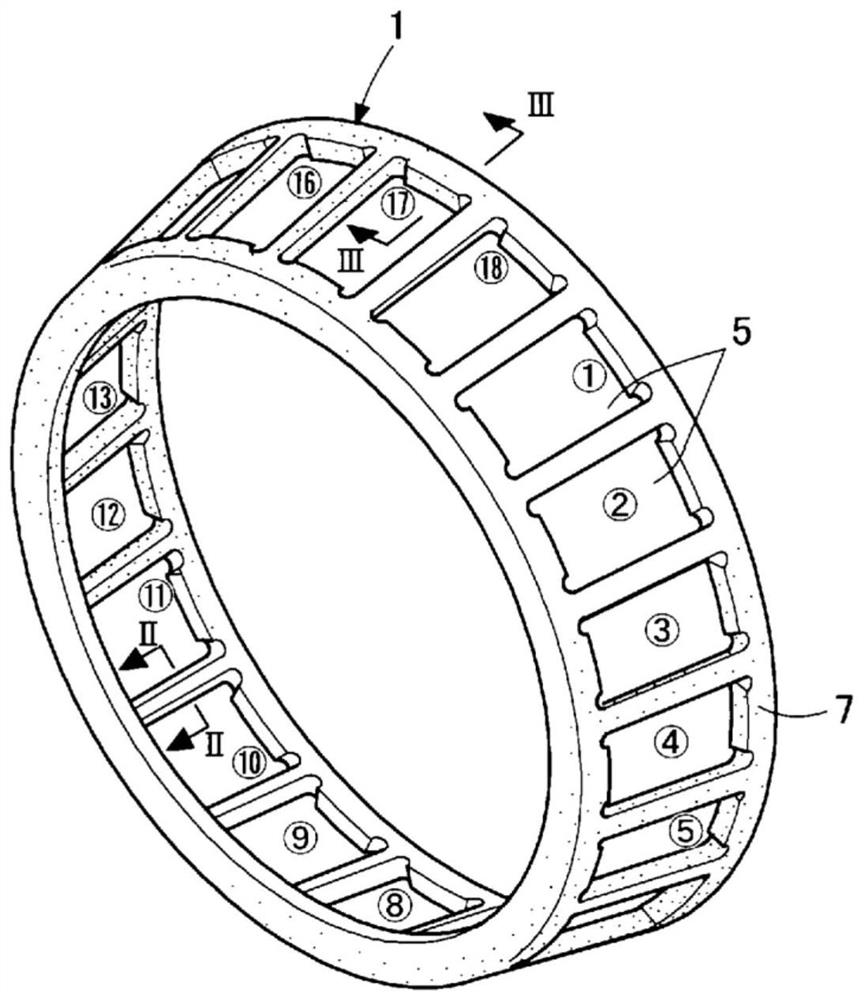

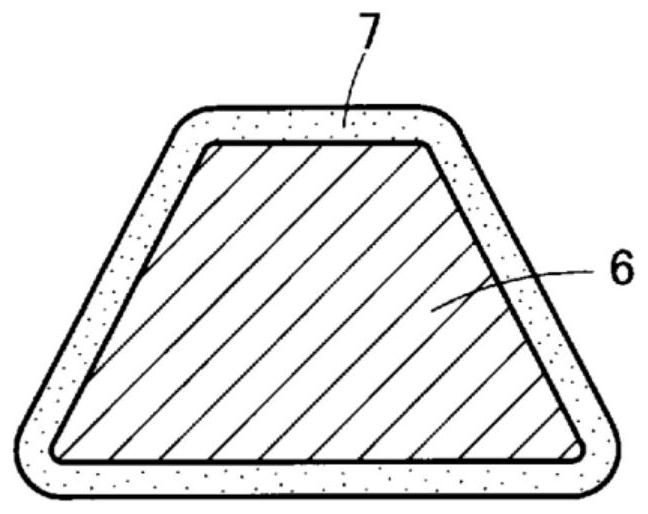

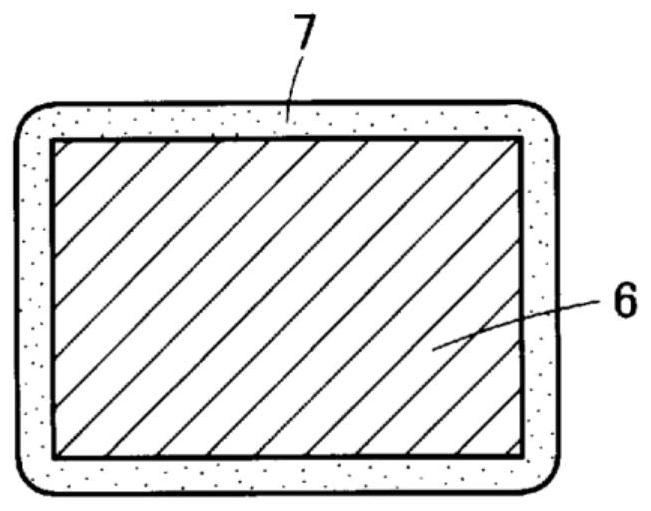

[0049] Using polyamide resin (PA) cages (hereinafter referred to as standard cages) for tapered roller bearings (inner diameter 130mm, outer diameter 240mm, width 80mm) as the base material, on the surface, two-liquid collision mixing Type spray gun (manufactured by American Gasmer Corporation: GX) will "polyurea resin composed of components containing aliphatic polyisocyanate, polyoxyalkylene polyols with amino groups as terminal groups and chain extenders" (US Line Made by Company X: LINE-X) is sprayed on the entire surface of the base material of the cage and reacted and cured to form a polyurea resin film with an average film thickness of 1.0mm, and to manufacture cages with a resin film for roller bearings ( figure 1 form shown).

Embodiment 2

[0051] A resin-coated cage for a roller bearing was produced in exactly the same manner as in Example 1 except that a polyurea resin film having an average film thickness of 0.5 mm was formed.

Embodiment 3

[0053] A resin-coated cage for a roller bearing was manufactured in exactly the same manner as in Example 1 except that a polyurea resin film having an average film thickness of 1.8 mm was formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com