Kitchen garbage truck rear door assembling and welding method and assembling and welding tool

A technology for garbage trucks and back doors, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve problems such as machining errors, position deviation of hinged ears on the back door cylinder seat, and affect the precise positioning of the rear door cylinder seat, so as to ensure accuracy , The structure of the positioning frame is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] A specific embodiment of the welding tool for the rear door of the kitchen garbage truck of the present invention:

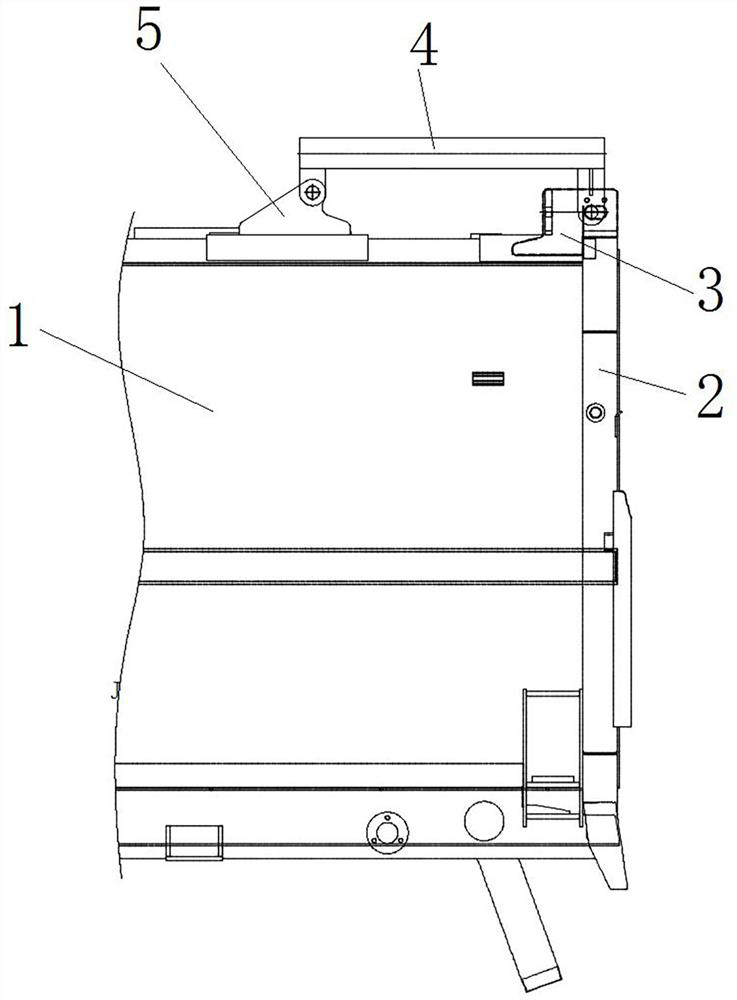

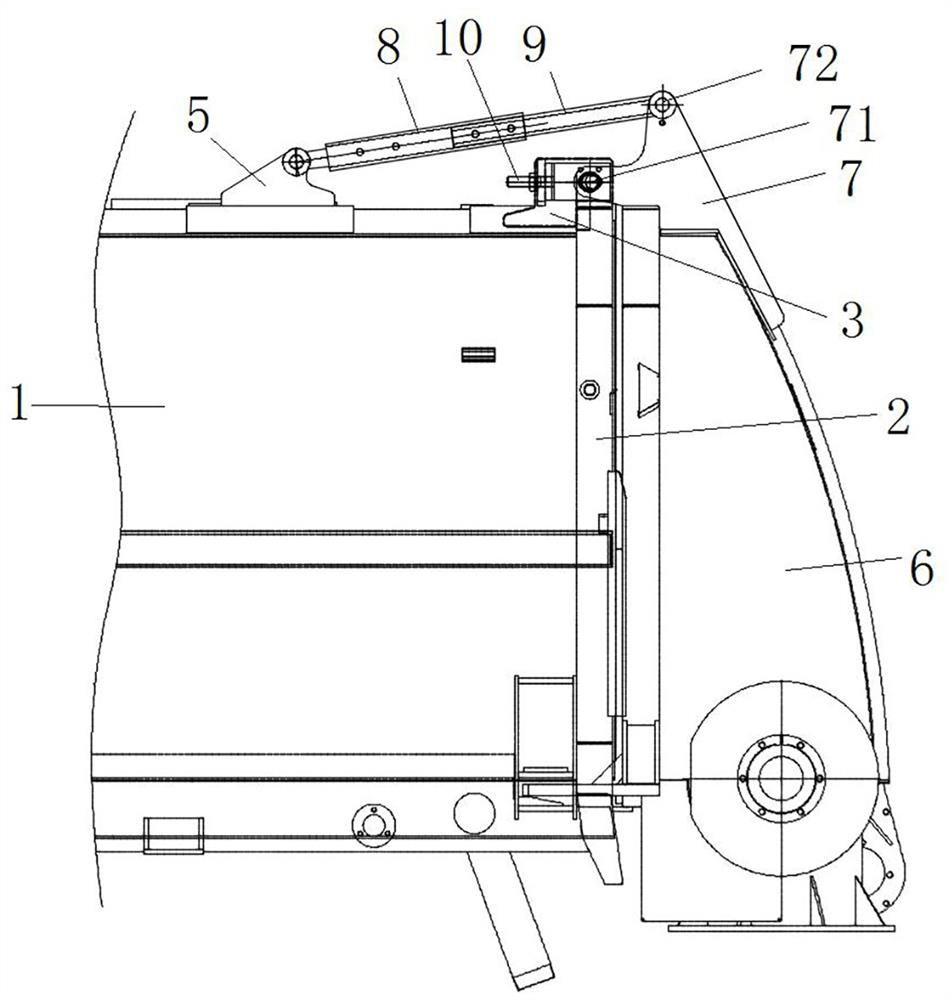

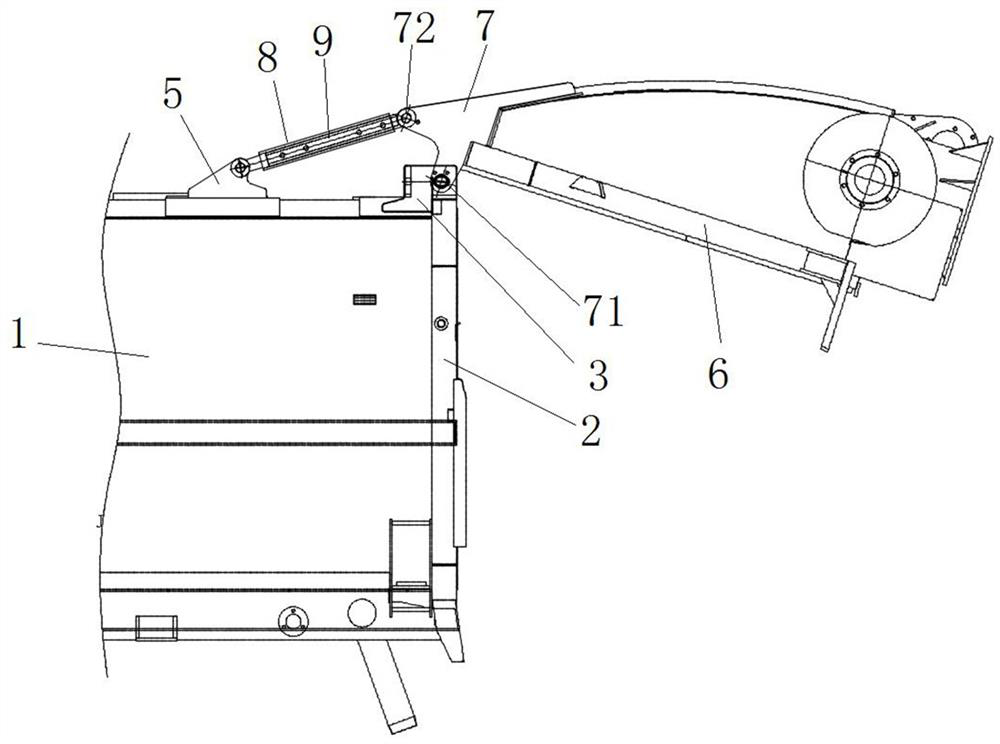

[0039] like figure 1 and Figure 4 As shown, the welding tool for the back door of the kitchen garbage truck includes a positioning frame 4, and the positioning frame 4 includes a positioning hole 42 of the hinge seat of the rear door, which is used to pass through the hinge hole 3 on the hinge seat 3 of the rear door to pass through the corresponding positioning shaft, and also includes a support for the oil cylinder. Seat positioning hole 43 is used to communicate with the hinged hole on the oil cylinder support 5 to wear the corresponding positioning shaft, so that the oil cylinder support 5 is positioned as a reference with the rear door hinge seat 3 and is fixed on the carriage 1 by spot welding.

[0040] like Figure 5 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com