Grinding and polishing integrated crystal perforating device

A technology of perforating device and crystal, applied in surface polishing machine tools, fine working devices, grinding/polishing equipment, etc., can solve the problems of low drilling efficiency, affecting the appearance of crystal, small aperture, etc., to improve drilling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

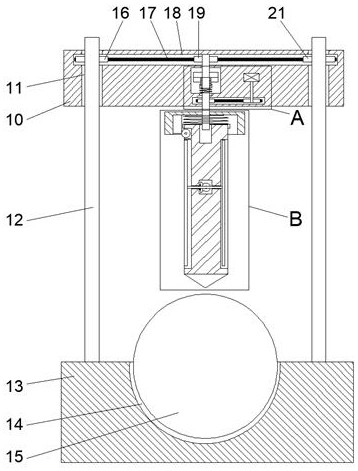

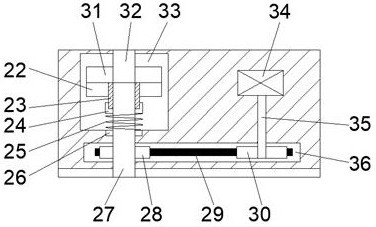

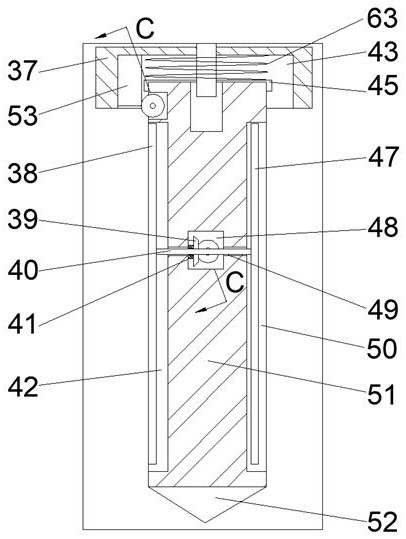

[0016] Bonded below Figure 1-4 The present invention will be described in detail, in which it is convenient for the description, the orientation of the following statement is as follows: The above-mentioned left and right directions figure 1 The projection relationship of the projection is consistent with the front and back and so on.

[0017] With a polishing device according to Figs. 1-4, a lifting casing 10 is provided, and a fixed base 13 is provided on the lower side of the lifting casing 10, and an opening is provided upward in the fixed base 13. The crystal fixing chamber 14 is placed in the crystal fixation chamber 14, and the lifting casing 10 is provided with two left and right symmetrical and up and down the lifting chamber 11, and an end surface is provided in the lifting casing 10. The upper side of the gear chamber 33, the upper side of the end surface gear chamber 33 is provided on the left side of the lifting chamber 11 to the left side and extend to the right to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap