Method for recovering byproduct chloromethane in maltol production process

A production process, technology of methyl chloride, applied in the field of recovery of by-product methyl chloride, can solve problems such as difficulty in recovery of methyl chloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

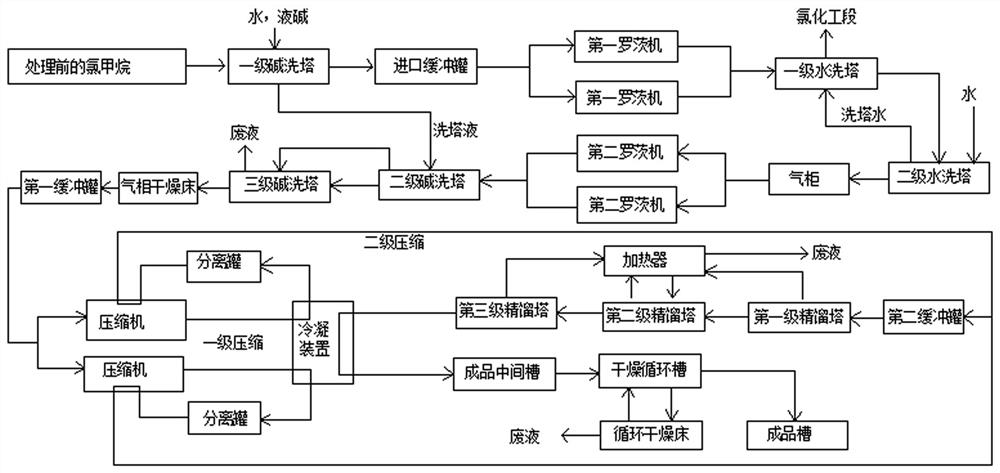

[0018] see figure 1 , a method for recovering by-product methyl chloride in a maltol production process, comprising the following steps:

[0019] (1) Pass methyl chloride into the first-level alkali washing tower, add a mixture of water and liquid caustic soda into the first-level alkali washing tower as the alkali washing liquid and the pH value is ≥ 10.0, and then pass it into the import buffer tank;

[0020] (2) The methyl chloride in the inlet buffer tank is washed by two first Roots machines arranged in parallel, the washing water of the two-stage washing tower enters from the second washing tower, and the washing water of the second washing tower enters The primary water washing tower finally enters the maltol chlorination section;

[0021] (3) Methyl chloride discharged from the secondary water washing tower enters the gas cabinet, the height of the gas cabinet is maintained at 2.00m, and then pressurized to 15.0kPa by two second Roots machines arranged in parallel to ...

Embodiment 2

[0026] see figure 1 , a method for recovering by-product methyl chloride in a maltol production process, comprising the following steps:

[0027] (1) Pass methyl chloride into the first-level alkali washing tower, add a mixture of water and liquid caustic soda into the first-level alkali washing tower as the alkali washing liquid and the pH value is ≥ 10.0, and then pass it into the import buffer tank;

[0028] (2) The methyl chloride in the inlet buffer tank is washed by two first Roots machines arranged in parallel, the washing water of the two-stage washing tower enters from the second washing tower, and the washing water of the second washing tower enters The primary water washing tower finally enters the maltol chlorination section;

[0029] (3) Methyl chloride discharged from the secondary water washing tower enters the gas cabinet, the height of the gas cabinet is maintained at 2.50m, and then pressurized to 22.5kPa by two second Roots machines arranged in parallel, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com