Fluorine-containing vinyl chloride copolymer, its preparation method, its composition and resin product made from the composition

A vinyl chloride-based resin and vinyl chloride technology, applied in the field of resin products, can solve the problems of neglect, easy decomposition, and high reaction temperature, and achieve the effects of avoiding performance degradation, reducing melt viscosity, and excellent self-plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0124]

[0125] The preparation method of the vinyl chloride copolymer of the present invention is the preparation method of the above-mentioned vinyl chloride copolymer, which comprises: making vinyl chloride, the monomer represented by the above formula (1) and the monomer represented by the above formula (2) The raw materials of the body are subjected to a copolymerization reaction.

[0126] The details of vinyl chloride, the monomer represented by formula (1), the monomer represented by formula (2) and other monomers have been described above, and will not be repeated here.

[0127] Examples of copolymerization reactions of the present invention include, without limitation, block polymerization, random polymerization, graft polymerization, gradient polymerization. Among them, random polymerization is preferable from the viewpoint of expressing the technical effect of the present invention more favorably, that is, the molecular chain of the vinyl chloride-based copolymer ...

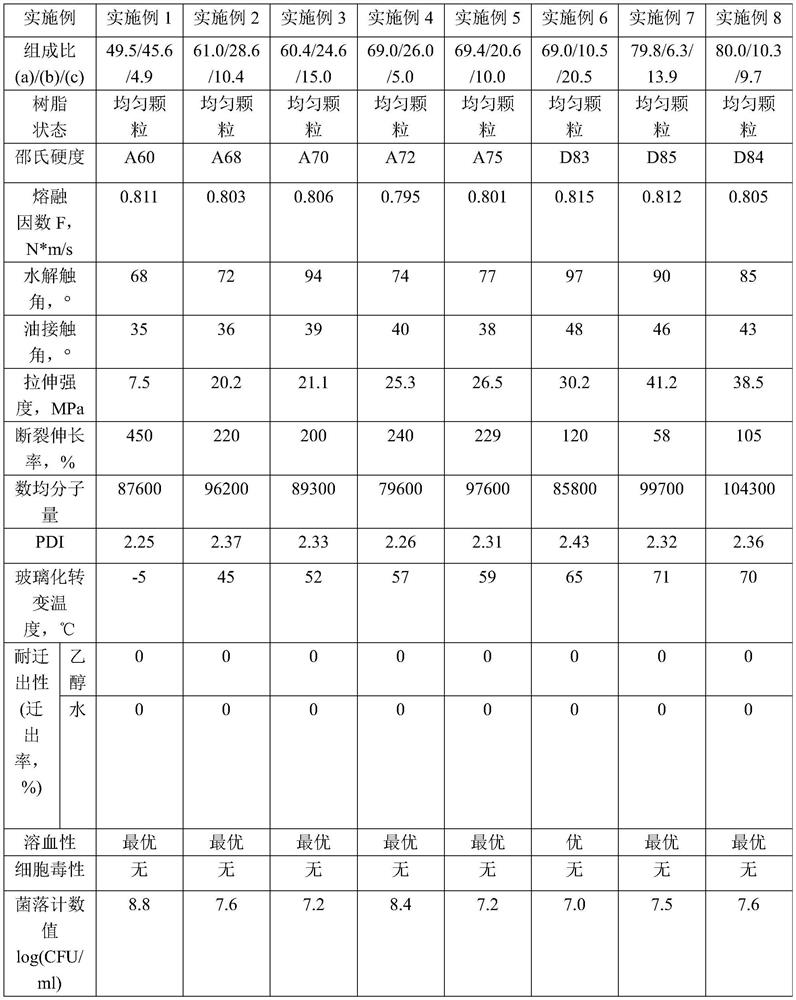

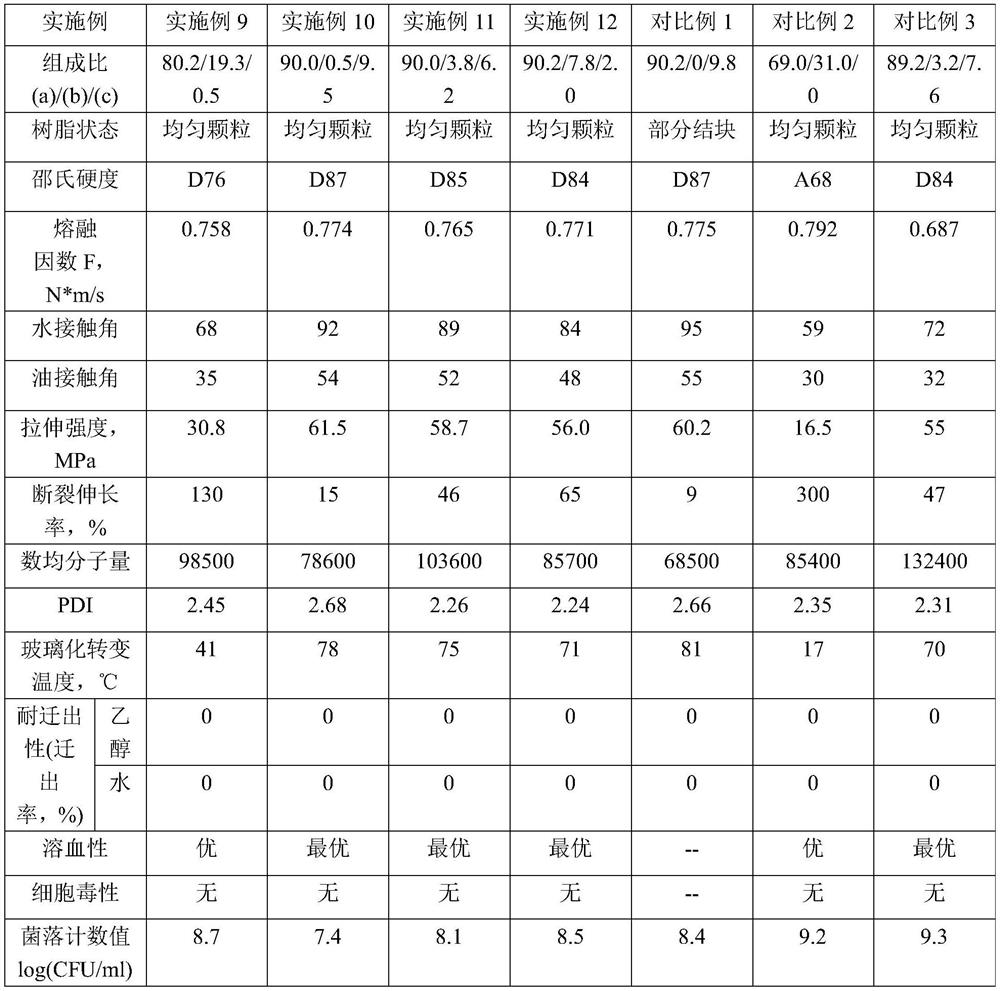

Embodiment 1

[0192] In a stainless steel micro-reactor with an internal volume of 200ml of stirring blades, 100g of deionized water, 10.4g of 2 mass % PVA aqueous solution, 0.042g of hydroxypropylmethylcellulose, 0.05g of azobisisobutyronitrile, The molecular weight of 24.84g is polypropylene glycol monomethacrylate (PPGMA-375, the situation of x=5 in the formula (1)) of 375, 2.16g hexafluorobutyl methacrylate (HFBMA), nitrogen gas 5min replaces reactor in the air. Then, 27.0 g of VC monomers were introduced into the reactor. After pre-stirring for 60 minutes, the temperature was raised to 70°C to start polymerization. It should be noted that the mass ratio of the monomers was VC:PPGMA-375:HFBMA=50:46:4, and the polymerization reaction time was 8 hours. After the polymerization reaction was completed, unreacted VC monomer was reclaimed, and the polymerization product was alternately washed with a large amount of deionized water and ethanol to obtain 50.5 g of the vinyl chloride copolymer ...

Embodiment 2

[0194] Change the feed mass ratio of VC and PPGMA-375, HFBMA to be VC:PPGMA-375: HFBMA=62:30:8 and the polymerization reaction time is 7.5 hours, except that, obtain white solid in the same manner as Example 1 51.2 g of granular vinyl chloride copolymers, the composition of which is 61.0% by mass of the structural unit (a) and 28.6% by mass of the structural unit (b) based on the total mass of the vinyl chloride copolymer. The content of (c) was 10.4% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| grafting amount | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com