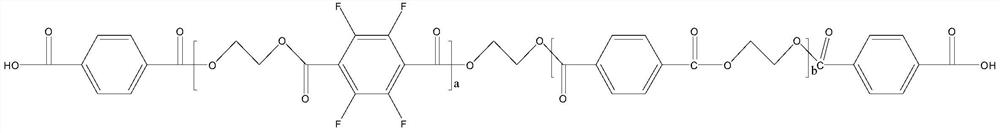

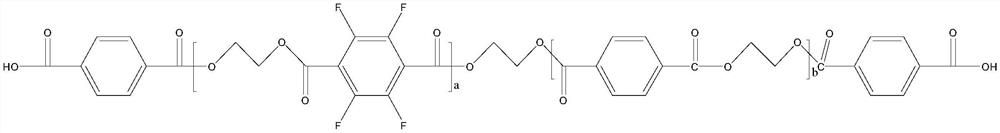

High-transmittance modified PET resin and application thereof

A high transmittance and modified technology, applied in the field of PET, can solve the problem of low transmittance of PET resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1mol of terephthalic acid and 1.01mol of ethylene glycol were added to the reactor, and the temperature was slowly raised to 240°C under a pressure of 0.5mpa for 6 hours of continuous reaction.

[0034] Remove the 0.5mpa pressure, start vacuuming, remove the generated water, and remove the vacuum when no more water is distilled out in the return line. Add 0.01mol of tetrafluoroterephthalic acid, apply a pressure of 0.5mpa, and keep the temperature at 240°C for 2 hours.

[0035] Remove the 0.5mpa pressure, start vacuuming, add a total mass of 0.05% antimony acetate catalyst, start heating up to 270°C, and continue the vacuum polycondensation reaction until the stirring power feedback value reaches the set value.

Embodiment 2

[0037] 1mol of terephthalic acid and 1.005mol of ethylene glycol were added to the reactor, and the temperature was slowly raised to 240°C under a pressure of 0.5mpa for 6 hours of continuous reaction.

[0038] Remove the 0.5mpa pressure, start vacuuming, remove the generated water, and remove the vacuum when no more water is distilled out in the return line. Add 0.005mol of tetrafluoroterephthalic acid, apply a pressure of 0.5mpa, and keep the temperature at 260°C for 10 hours.

[0039] Remove the 0.5mpa pressure, start vacuuming, add a total mass of 0.07% antimony acetate catalyst, start heating up to 280°C, and continue the vacuum polycondensation reaction until the stirring power feedback value reaches the set value.

Embodiment 3

[0041] 1mol of terephthalic acid and 1.006mol of ethylene glycol were added to the reactor, and the temperature was slowly raised to 250°C under a pressure of 0.5mpa for 6 hours of continuous reaction.

[0042] Remove the 0.5mpa pressure, start vacuuming, remove the generated water, and remove the vacuum when no more water is distilled out in the return line. Add 0.006mol of tetrafluoroterephthalic acid, apply a pressure of 0.5mpa, and keep the temperature at 260°C for 6 hours.

[0043] Remove the 0.5mpa pressure, start vacuuming, add a total mass of 0.07% antimony acetate catalyst, start heating up to 270°C, and continue the vacuum polycondensation reaction until the stirring power feedback value reaches the set value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com