A method for refining and chemical enterprises to dispose of waste lubricating oil

A kind of waste lubricating oil, refining technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

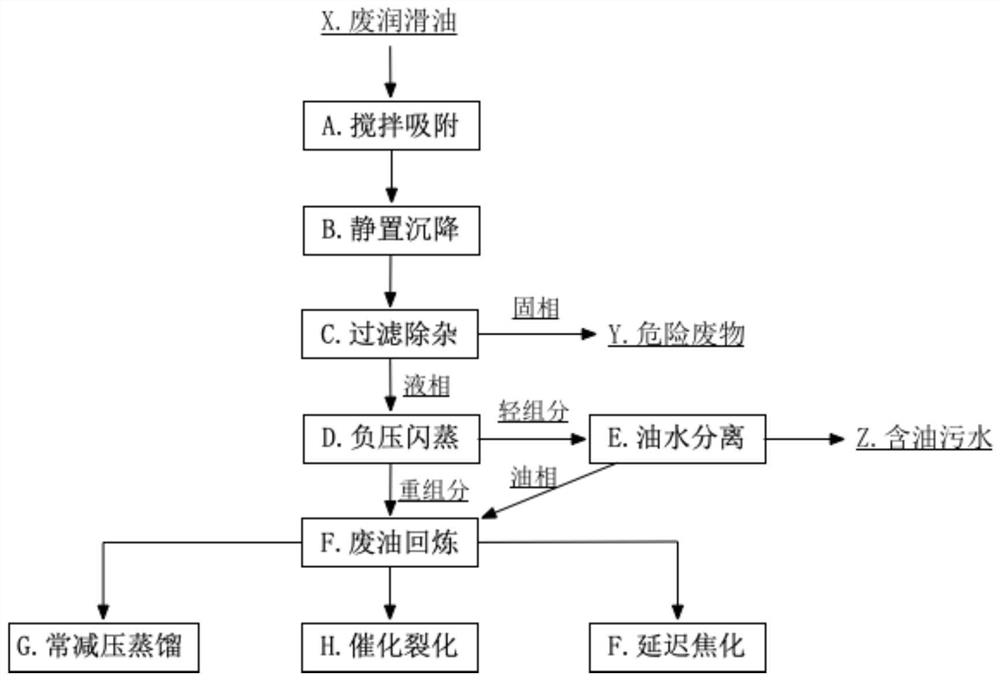

Image

Examples

Embodiment 1

[0059] The waste lubricating oil is mixed with 5.0wt.% clay, the operating temperature is 60°C, and the stirring time is 20min. After the reaction, the additives and impurities in the waste lubricating oil react with the clay to adsorb and remove;

[0060] The solid phase and the liquid phase are obtained by standing and settling through secondary filtration (50 meshes for the first stage and 150 meshes for the second stage). The solid phase is classified as hazardous waste for disposal;

[0061] The liquid phase enters the negative pressure flash device, the operating temperature is 50°C, and the operating pressure is 70KPa absolute.

[0062] The obtained fraction is separated from oil and water to obtain oily sewage and oil phase. The oily sewage is merged into the oily sewage line in the plant area for treatment, and the obtained oil phase and the heavy components remaining in the flash are sent to the raw material supply line of the catalytic cracking unit, and then opera...

Embodiment 2

[0064] The waste lubricating oil is mixed with 8.0wt.% clay, the operating temperature is 70°C, and the stirring time is 30 minutes. After the reaction, the additives and impurities in the waste lubricating oil react with the clay to adsorb and remove;

[0065] The solid phase and the liquid phase are obtained by standing and settling through secondary filtration (80 meshes for the first stage and 150 meshes for the second stage). The solid phase is classified as hazardous waste for disposal;

[0066] The liquid phase enters the negative pressure flash device, the operating temperature is 60°C, and the operating pressure is 65KPa absolute.

[0067] The obtained fraction is separated from oil and water to obtain oily sewage and oil phase. The oily sewage is merged into the oily sewage line in the plant area for treatment, and the obtained oil phase and the heavy components remaining in the flash are sent to the raw material supply line of the catalytic cracking unit, and then ...

Embodiment 3

[0069] The waste lubricating oil is mixed with 10.0wt.% clay, the operating temperature is 80°C, and the stirring time is 40min. After the reaction, the additives and impurities in the waste lubricating oil react with the clay to adsorb and remove;

[0070] The solid phase and the liquid phase are obtained by standing and settling through secondary filtration (80 meshes for the first stage and 200 meshes for the second stage). The solid phase is classified as hazardous waste for disposal;

[0071] The liquid phase enters the negative pressure flashing device, the operating temperature is 70°C, and the operating pressure is 50KPa absolute;

[0072] The obtained fraction is separated from oil and water to obtain oily sewage and oil phase. The oily sewage is merged into the oily sewage line in the plant area for treatment, and the obtained oil phase and the heavy components remaining in the flash are sent to the raw material supply line of the catalytic cracking unit, and then o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com