Straw decomposing bacterial agent in cold regions, its preparation method and application

A production method and antibacterial agent technology, applied in the field of agricultural preparations, can solve the problems of high manpower and economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The invention relates to a straw decomposing bacterial agent in cold regions, which consists of microcapsules of low-temperature bacterial flora and bacteria powder of normal-temperature lignocellulose-decomposing flora.

[0049] (1) Production of low-temperature flora microcapsules:

[0050] ①Preparation of improved low-temperature bacterial culture medium: the preparation contains glucose 15g / L, K 2 HPO 4 1.0 g / L, KH 2 PO 4 1.0g / L, peptone 6g / L, beef extract 6g / L, yeast powder 3g / L, MgSO 4 ·7H 2 O0.1g / L, sodium acetate 2g / L, diammonium hydrogen citrate 2g / L, MnSO 4 ·H 2 O 0.05g / L, Tween 801mL / L improved low-temperature bacterial culture medium. Divide into 500mL blue cap bottles, each bottle contains 350mL. Store in a 4°C refrigerator for later use.

[0051] ②Floral culture: Inoculate Lactobacillus plantarum, Lactococcus lactis subsp. lactis, Lactococcus, Arthrobacter globosa and Rhodococcus into the improved low-temperature culture medium. After culturing a...

Embodiment 2

[0061] The invention relates to a straw decomposing bacterial agent in cold regions, which is composed of: freeze-dried powder of low-temperature bacterial flora and bacterial powder of normal-temperature lignocellulose-decomposing bacterial flora.

[0062] (1) Production of low-temperature flora freeze-dried powder:

[0063] ①Preparation of improved low-temperature bacterial culture medium: the preparation contains glucose 15g / L, K 2 HPO 4 1.0 g / L, KH 2 PO 4 1.0g / L, peptone 6g / L, beef extract 6g / L, yeast powder 3g / L, MgSO 4 ·7H 2 O0.1g / L, sodium acetate 2g / L, diammonium hydrogen citrate 2g / L, MnSO 4 ·H 2 O 0.05g / L, Tween 801mL / L improved low-temperature bacterial culture medium. Divide into 500mL blue cap bottles, each bottle contains 350mL. Store in a 4°C refrigerator for later use.

[0064] ②Floral culture: Inoculate Lactobacillus plantarum, Lactococcus lactis subsp. lactis, Lactococcus, Arthrobacter globosa and Rhodococcus into the improved low-temperature culture...

Embodiment 3

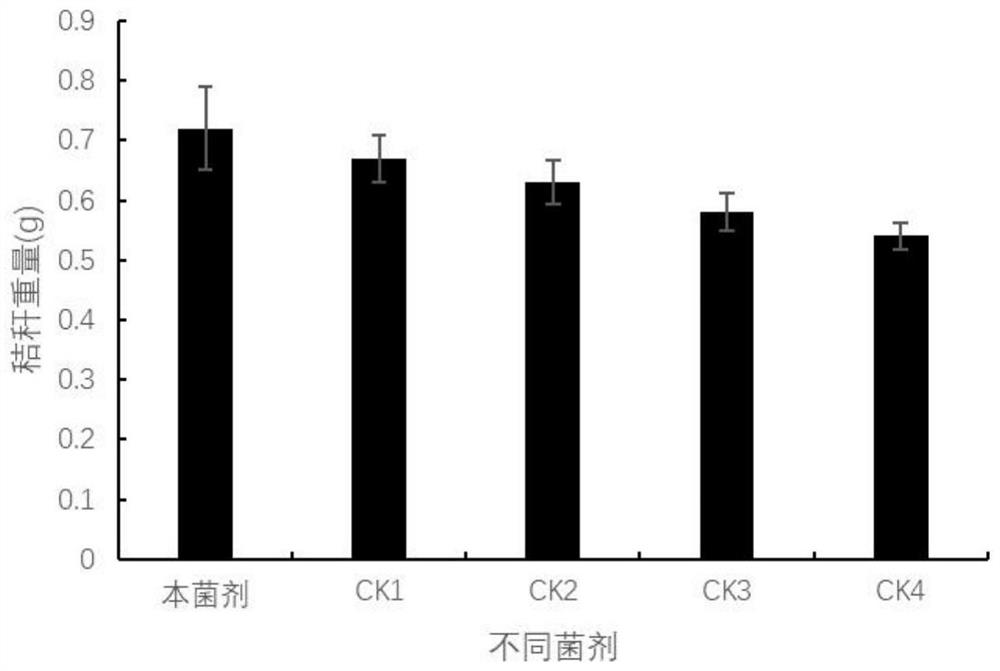

[0070] The bacterial agent prepared in Example 1 was used as the experimental group, and was simultaneously inoculated with four commercially available straw-decomposing bacterial agents CK1, CK2, CK3, and CK4 on a medium with rice straw as the only carbon source, and fermented at 28°C for 15 days , to determine the weight-reducing ability of rice straw. Under different treatments, the analysis of rice straw weight loss is as follows: figure 1 shown. Depend on figure 1 It can be seen that the straw weight loss under the treatment of the bacterial agent, CK1, CK2, CK3, and CK4 was 0.72g, 0.67g, 0.63g, 0.58g, and 0.54g, and the weight loss rates were 44.2%, 41.10%, and 38.65% respectively. %, 35.58%, 33.12%. It shows that the straw transformation ability of this inoculum agent under the same conditions is stronger than that of the four commercially available inoculum agents used in the experiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap