A mud pipe extension system and its construction method

A mud pipe and mud technology, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as difficulty in extending mud pipes, and achieve the effect of saving space and ensuring liquid level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

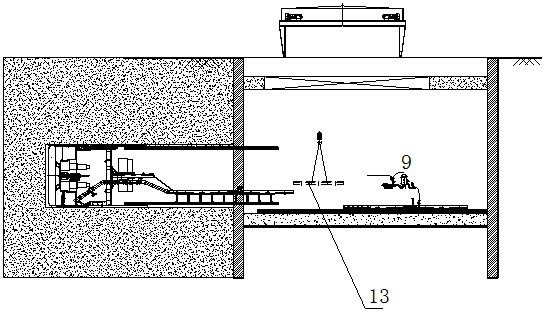

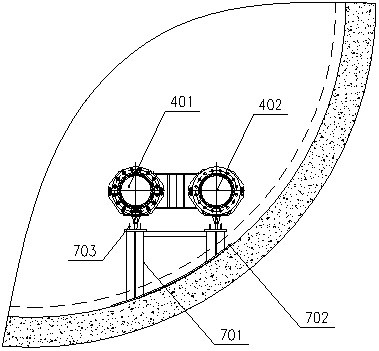

[0045] Embodiment 1, a mud pipe extension system, such as Figure 1-Figure 4 As shown, it includes a slurry inlet pipeline and a slurry discharge pipeline connected between the main engine mud pipeline 101 of the roadheader main engine 1 and the mud station, and the slurry inlet pipeline and the slurry discharge pipeline are both included in the originating well. The extension hose 8 connected to the mud station, before extending, the extension hose 8 is discharged in a folded shape in the originating shaft, and the extension hose 8 is connected with the main engine mud pipeline 101 through the walking mud hard pipe 4, and the walking mud hard pipe 4 includes the walking mud pipe 4 A pulp feeding hard pipe 401 and a walking pulp discharging hard pipe 402.

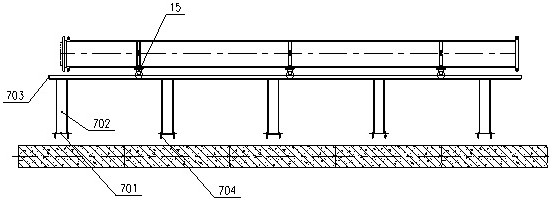

[0046] like Figure 5-Figure 8 As shown, the walking mud hard pipe 4 is connected with a walking unit 15, and a guide bracket 7 supporting the walking unit 15 is arranged in the starting guide tunnel. Hard pipe 4 moves fo...

Embodiment 2

[0051] Embodiment 2, a construction method of the mud pipe extension system when the split body of the mud-water balance roadheader starts, its principle is as follows Figure 9 As shown, the construction steps are as follows:

[0052] S1: The main machine 1 of the roadheader, the fixed mud pipe 11, the slurry collection unit 9, the extension hose 8, the walking mud hard pipe 4, the walking unit 15, and the guide bracket 7 have been lowered into the well and installed, and calibrated according to the length of the extension hose 8 Set position one and set position two, and make the extension hose 8 be located at set position one.

[0053] S2: Open the mud ball valve 6, the first gate valve 10, and the second gate valve 16, and close the ball valve 12 at the same time, so that the mud in the mud station flows into the main engine cabin of the main engine 1 of the roadheader. When the mud in the main engine cabin meets the excavation requirements of mud-water balance, Start dig...

Embodiment 3

[0059] Embodiment 3, a construction method of the mud pipe extension system when the mud-water balance roadheader is separated and started. When the roadheader is shut down for a long time during the start-up period, if the liquid level of the tunnel surface does not meet the requirements, open the slurry inlet pipe. The second gate valve 16 closes the first gate valve 10, opens the ball valve 12 between the slurry receiving unit 9 and the slurry inlet pipeline, and replenishes mud into the air cushion cabin to keep the liquid level of the tunnel face stable.

[0060] The structure of this embodiment is the same as that of Embodiment 1.

[0061] Other steps in this embodiment are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com