Tunnel inner groove cover plate laying device and method

A technology for laying devices and tunnels, used in tunnels, tunnel linings, mining devices, etc., can solve the problems of the overall cumbersomeness of cast iron cover plates, easy to smash fingers, and labor consumption, so as to avoid falling too fast and avoid labor loss. , the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

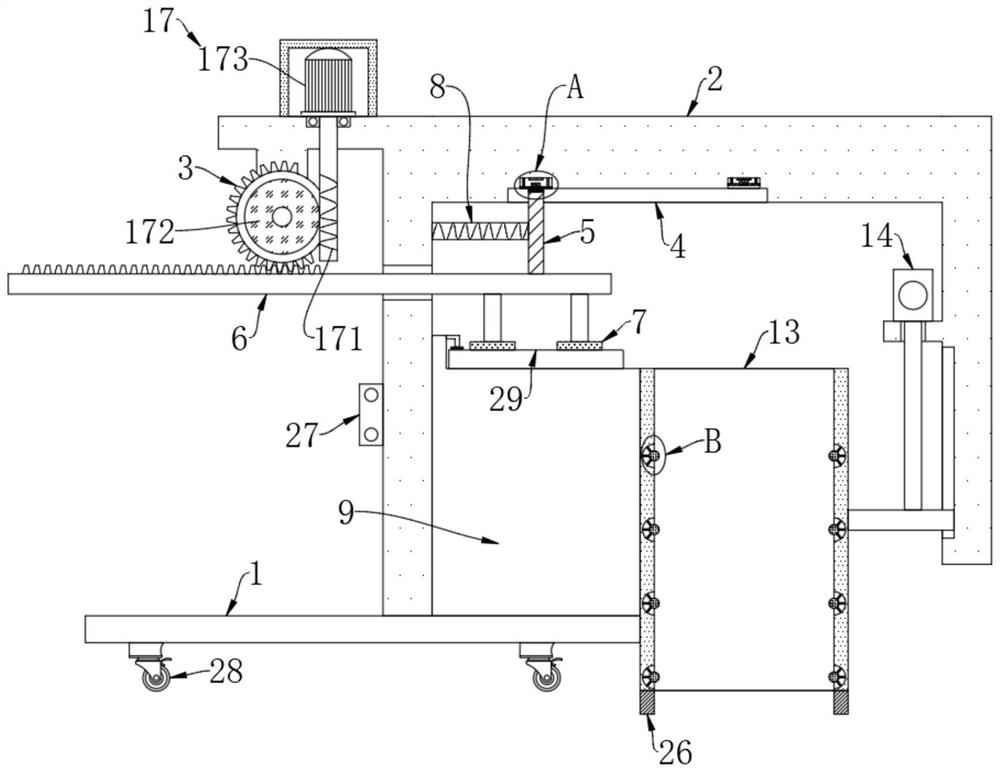

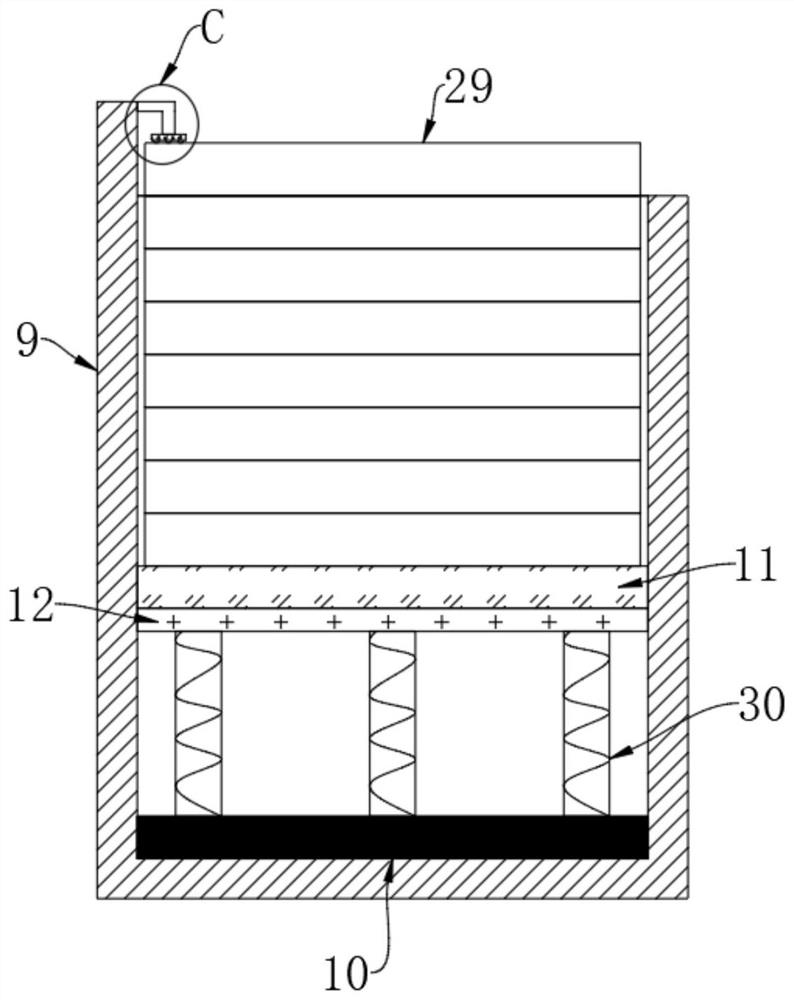

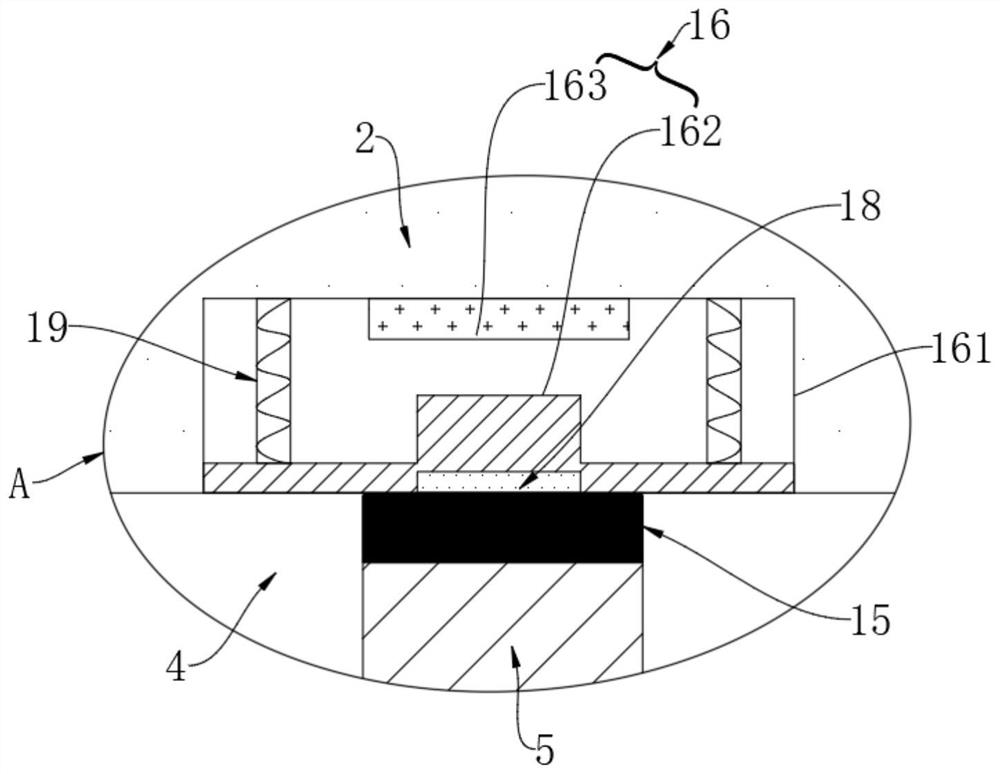

[0032] like Figure 1-5As shown, the trench cover laying device in the tunnel includes a base 1, and a plurality of universal wheels 28 are fixedly connected to the side wall of the lower end of the base 1, and the universal wheels 28 can be self-locking, and the setting of the universal wheels 28 is convenient for users. Move the whole device, the base 1 is fixedly connected with a bracket 2, the bracket 2 is rotatably connected with an incomplete gear 3, the bracket 2 is provided with a chute 4, and the chute 4 is slidably connected with a gear bar 6 through a slide bar 5, and the gear bar 6 is fixedly connected with two electromagnetic blocks 7, and one end of the gear rod 6 runs through the bracket 2 and meshes with the incomplete gear 3, the first tension spring 8 is fixedly connected between the slide bar 5 and the bracket 2, and the base 1 Fixedly connected with a placement box 9, the upper side wall of the placement box 9 is fixedly connected with a limiting plate 24 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com