Stainless steel checkered plate embossing machining device and process thereof

A processing device, stainless steel technology, applied in decorative arts, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of affecting the embossing effect, inability to clean dust, low efficiency, etc., to avoid dust overflow, timely Quick clean up, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

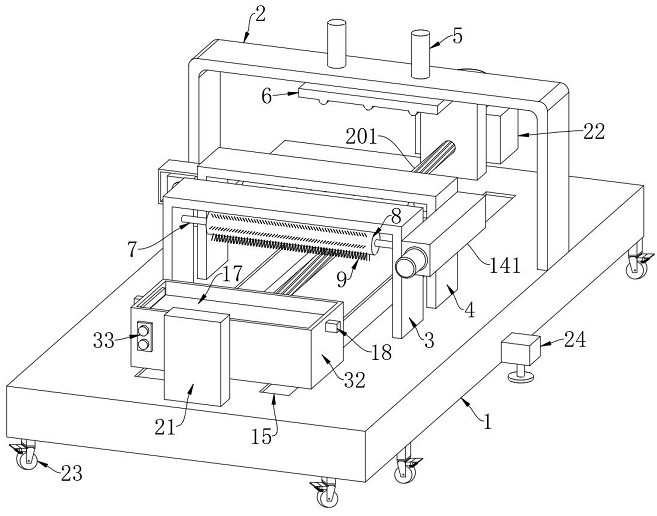

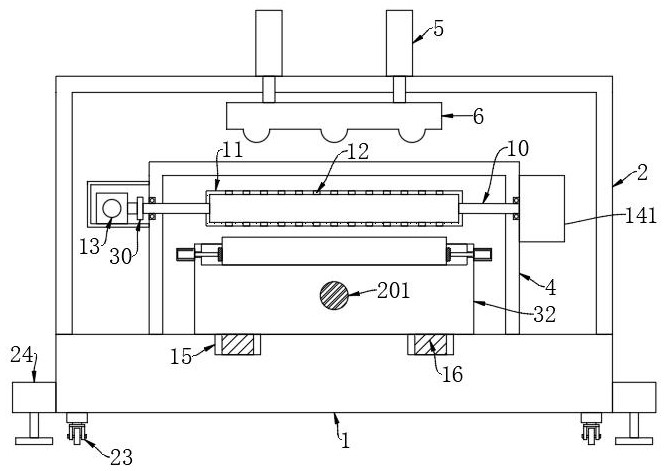

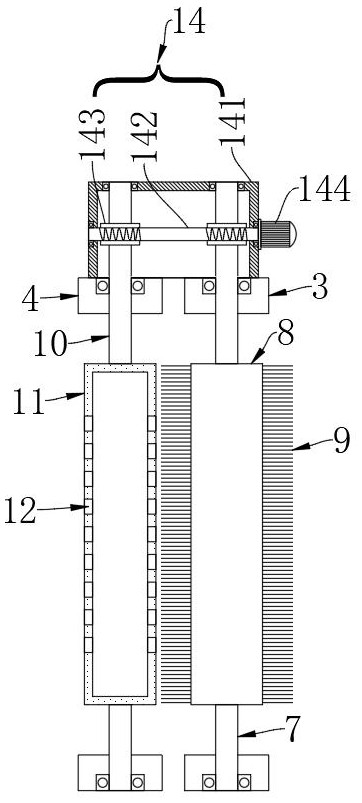

[0028] Such as Figure 1-6 As shown, a stainless steel checkered plate embossing processing device includes a processing table 1, a plurality of universal wheels 23 are fixedly connected to the lower end of the processing table 1, and the universal wheels 23 can be self-locking, and the setting of the universal wheels 23 is convenient. The user moves the whole device, and both sides of the processing table 1 are fixedly provided with a fixed box 24, and an electromagnetic plate 25 is embedded in the fixed box 24, and the electromagnetic plate 25 is fixedly connected with a metal plate 27 by a return spring 26, and the metal plate 27 is connected to the The fixed box 24 is slidably connected, and the metal plate 27 is fixedly connected with a rod 28, and the lower end of the rod 28 runs through the fixed box 24 and is fixedly connected with a friction blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com