Drilling device for steel plate and using method of drilling device

A technology of drilling device and steel plate, applied in the direction of boring/drilling, drilling/drilling equipment, components of boring machine/drilling machine, etc., can solve the problems of cumbersome process and labor-intensive, avoid labor loss and improve cooling effect, the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

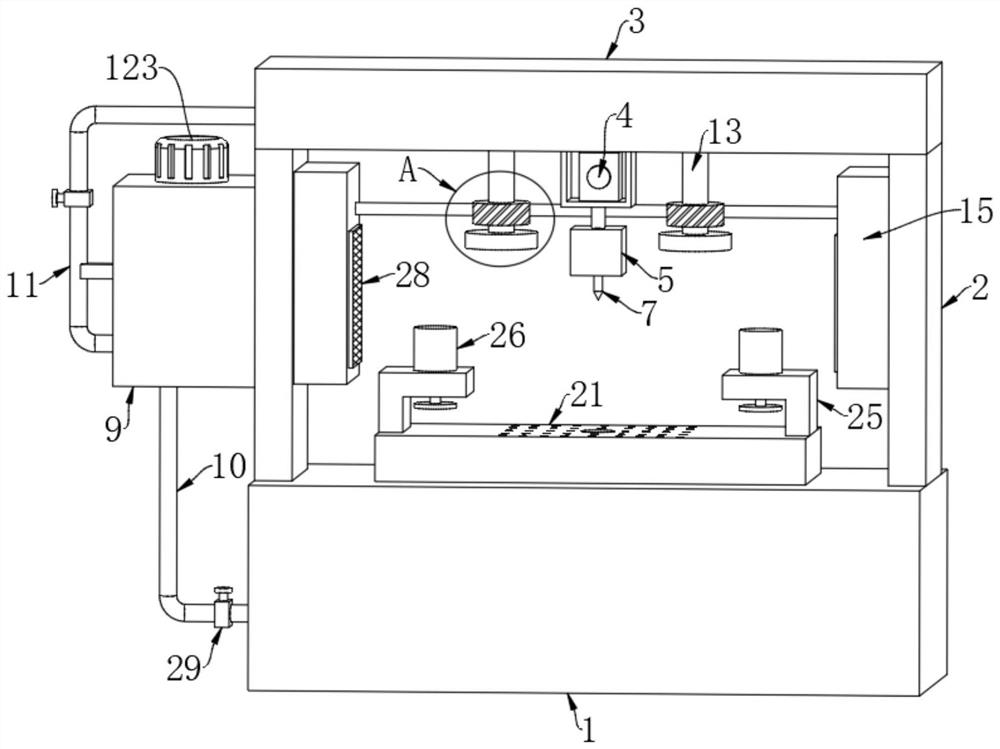

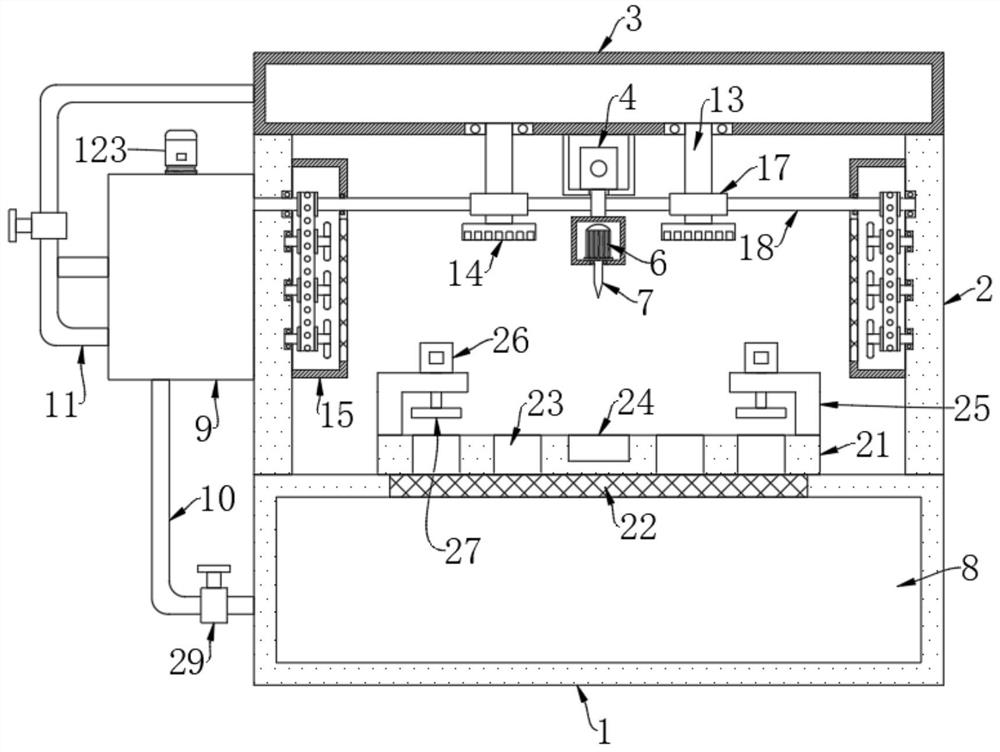

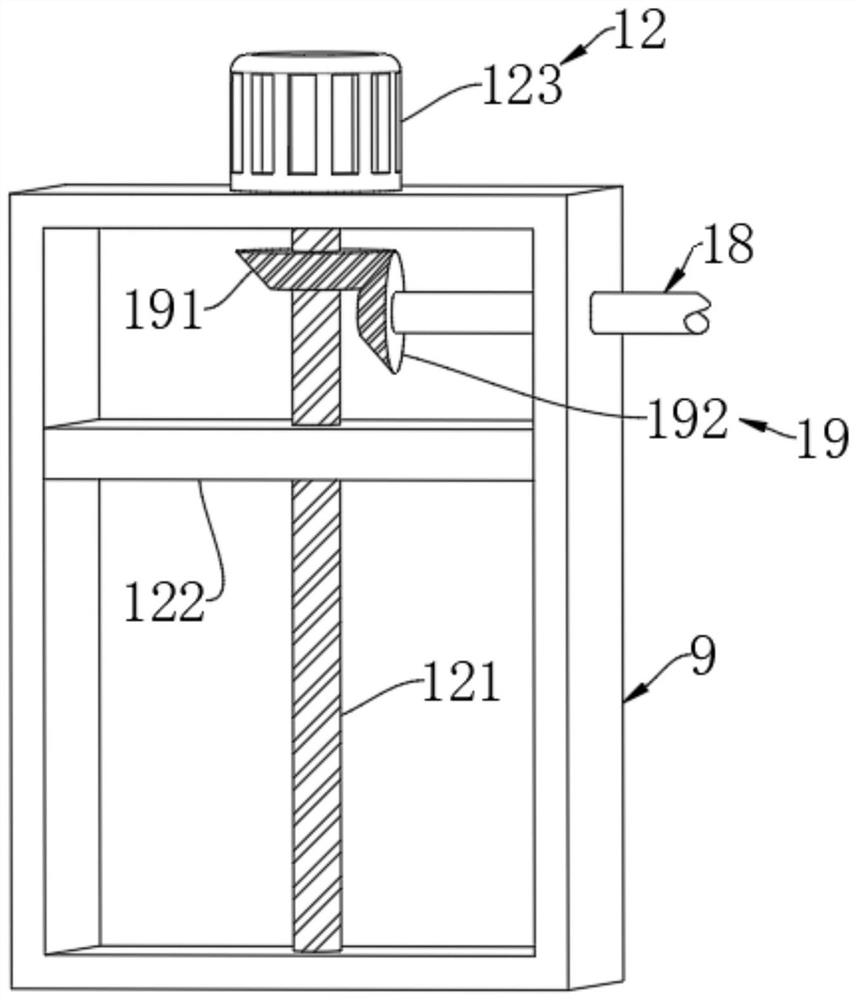

[0028] like Figure 1-5 As shown, a drilling device for steel plates includes a processing table 1, a support seat 21 is arranged on the processing table 1, a filter screen 22 is embedded in the upper end of the processing table 1, and a plurality of filter screens are provided on the support seat 21. 22 is matched with the drainage hole 23, and the support seat 21 is provided with a vacant slot 24. The setting of the support seat 21 is convenient for placing steel plates. With the cooperation of the filter screen 22, the generated waste water can be filtered and reused to save water resources. The support base 21 is fixedly connected with two fixing frames 25, and the fixing frame 25 is provided with a push rod motor 26. The push rod motor 26 The output end of the steel plate is fixedly connected with a pressure plate 27, and through the set push rod m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com