Internet-based intelligent ultrahigh-pressure hydraulic pump

A technology of ultra-high pressure and hydraulic pumps, which is applied to components, pumps, and pump control of elastic fluid pumping devices. Not high, poor output pressure stability, etc., to achieve the effect of omitting the connection and assembly process, compact hydraulic pump structure, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The technical principle and structural composition of the intelligent ultra-high pressure hydraulic pump of the present invention will be further described below in conjunction with the accompanying drawings.

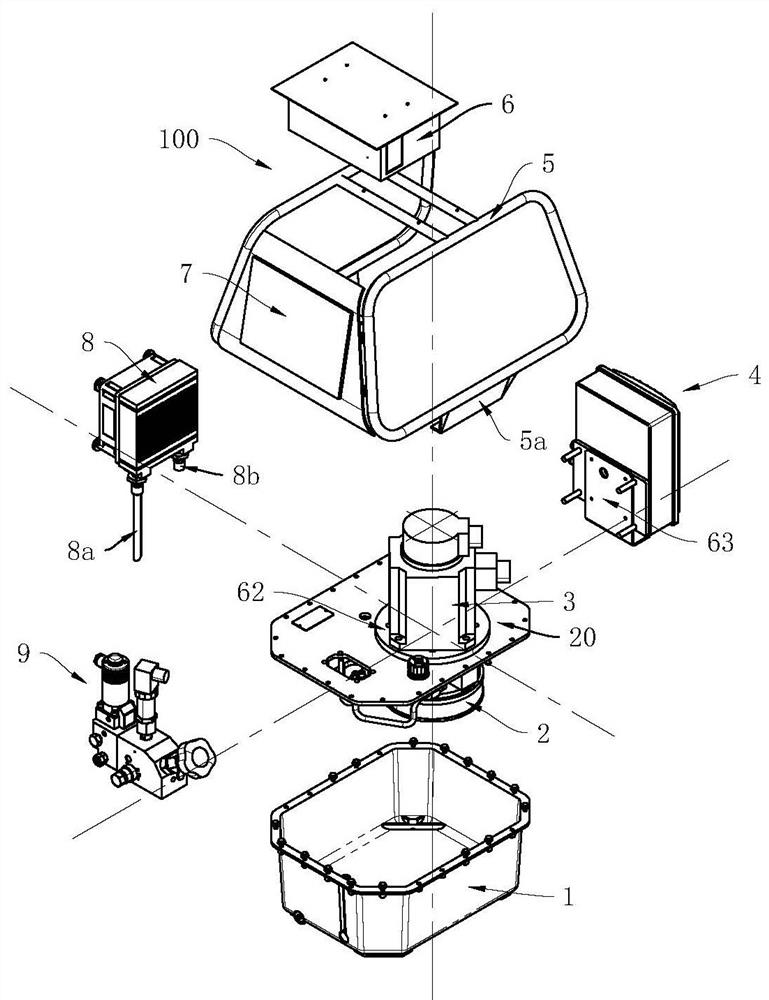

[0075] Such as Figure 1-4As shown, the intelligent ultra-high pressure hydraulic pump of the present invention includes a fuel tank module 1, a servo motor 3, an air cooler 8, a bracket module 100, a pump body module 2, a valve group module 9 and an electric control box 4.

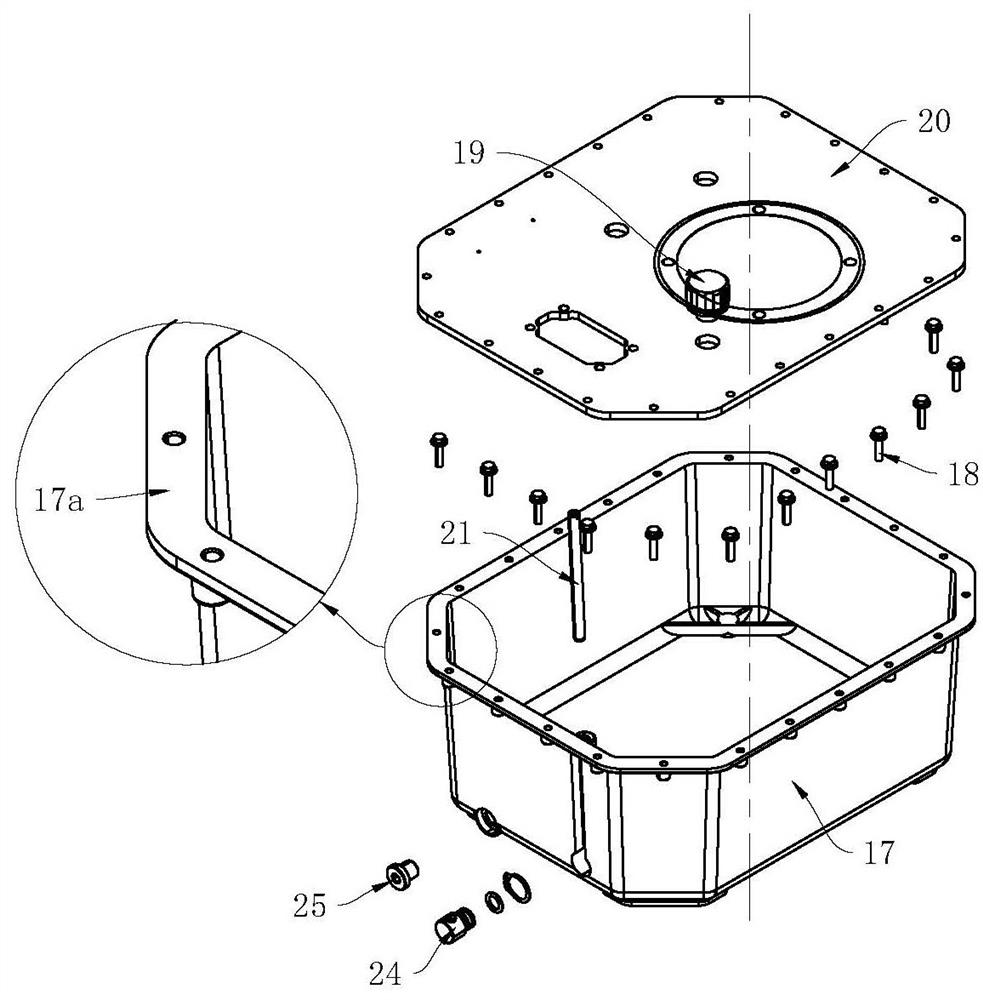

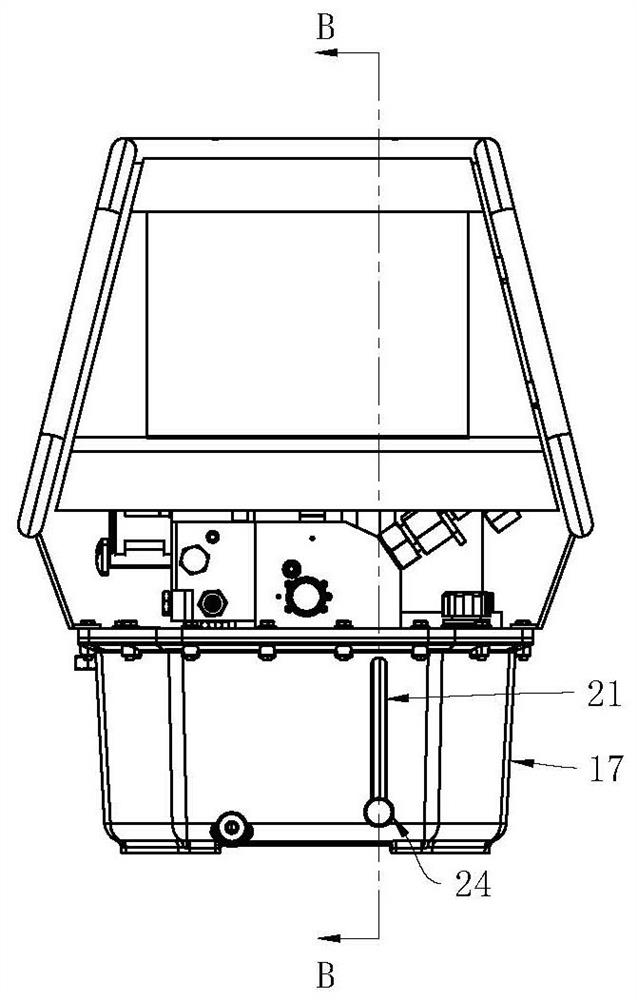

[0076] The fuel tank module 1 is the main supporting body of the intelligent ultra-high pressure hydraulic pump. The fuel tank module 1 is composed of fuel tank cover plate 20, fuel tank 17, oil level 21, oil level fixed head 24, oil drain plug 25 and other parts. The fuel tank 17 has a groove structure, the upper edge of the fuel tank 17 is provided with an outwardly turned flange edge 17a, and the fuel tank cover plate 20 is a flat structure, and the edge profile of the fuel tank cover pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com