A brake assembly suitable for hub motors

A hub motor and brake technology, which is applied in the direction of brake types, brake components, and axial brakes, etc., can solve problems such as the rapid change of the thickness difference of the brake disc, the inability to install the brake disc, and the overheating of the hub motor. To achieve the effect of shortening the braking response time, alleviating the heating problem, and uniform braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

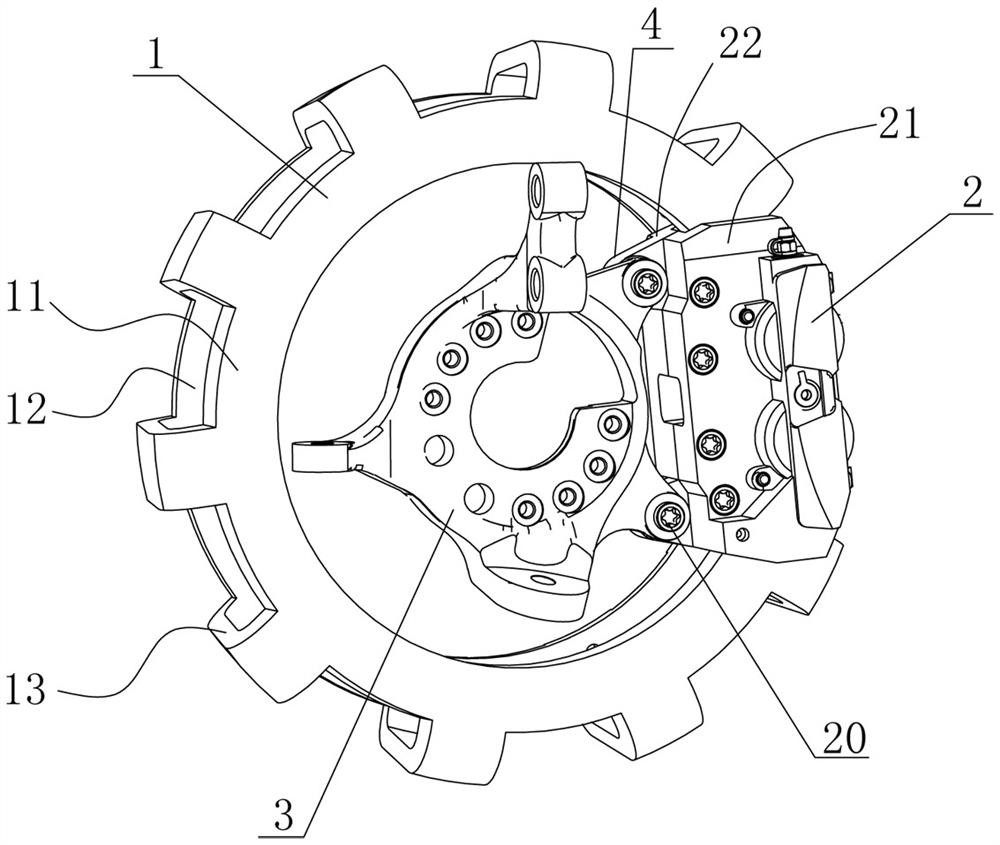

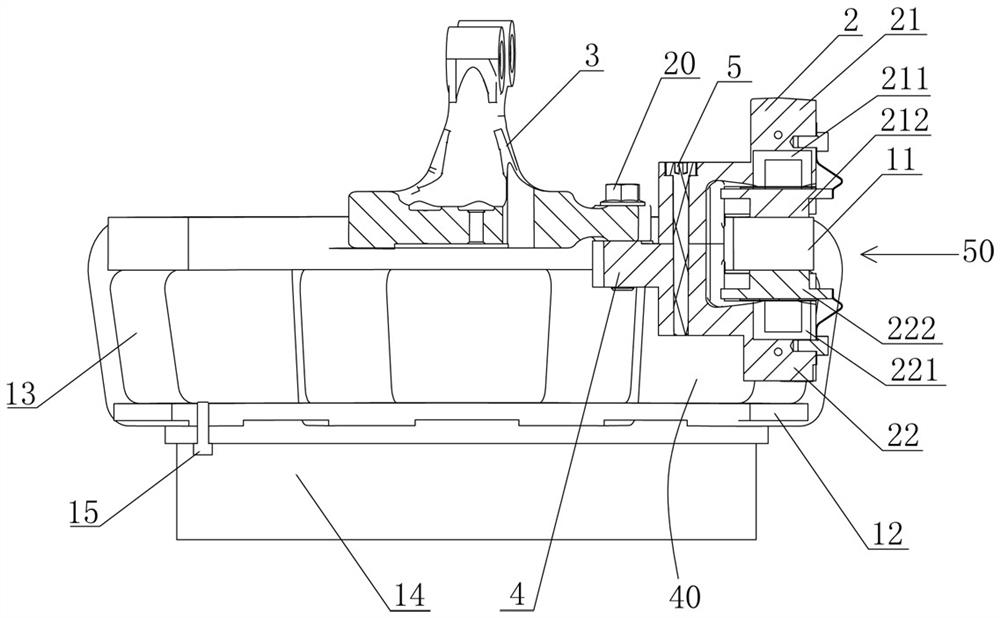

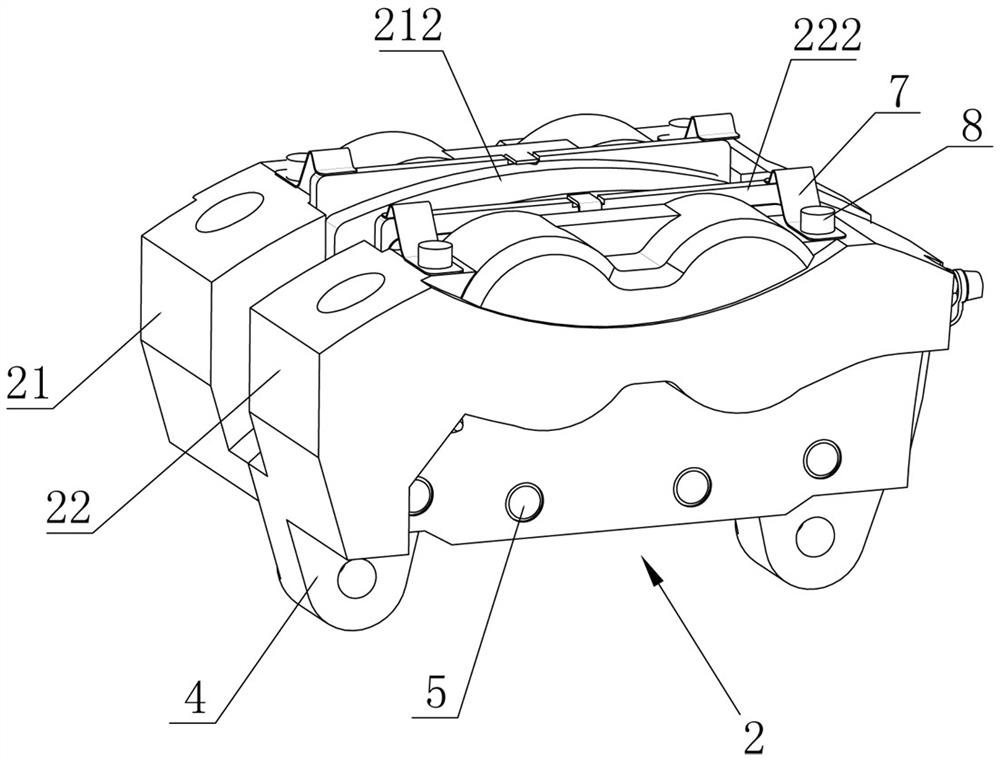

[0021] like figure 1 and figure 2 As shown, a brake assembly suitable for an in-wheel motor includes an inner-buckling annular brake disc 1, an opposite caliper 2 and a hub motor housing 14. The inner-buckling annular brake disc 1 has an internal The moving disc 11, the outer brake disc 12 and the connecting arm 13, the radially outer end of the inner brake disc 11 and the radially outer end of the outer brake disc 12 are connected by the connecting arm 13, the opposite caliper 2 radially A lug 4 for connecting with the chassis part 3 is extended inward. The chassis part 3 is a part of the chassis of the whole vehicle. not connected. The present invention specifies that the direction of the chassis component 3 is inward, and vice versa. the radially outward direction of the moving plate 1 .

[0022] The in-wheel motor housing 14 is connected to the outer brake disc 12 , the outer brake disc 12 is provided with several bolt holes along the circumferential direction, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com