Rotatable reduction friction composite metal damper

A metal damper and composite technology, applied in the field of dampers, can solve the problems of unstable effective area, waste, and inability to consume energy in stages, and achieve good energy consumption effects, easy on-site installation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

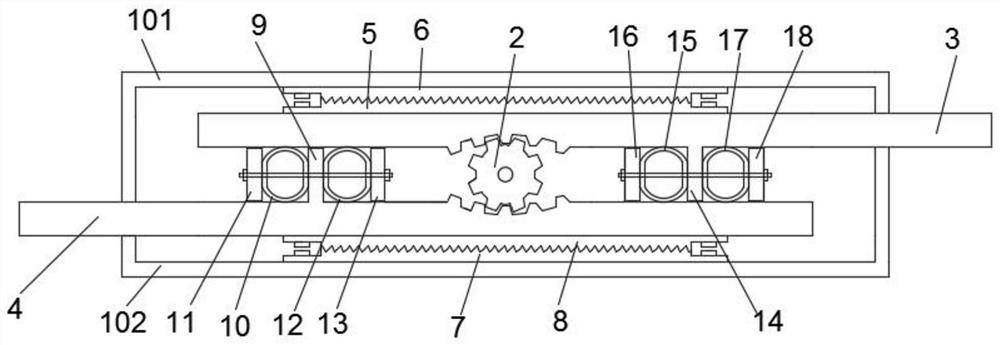

[0018] The directions shown in the accompanying drawings are up, down, left, and right.

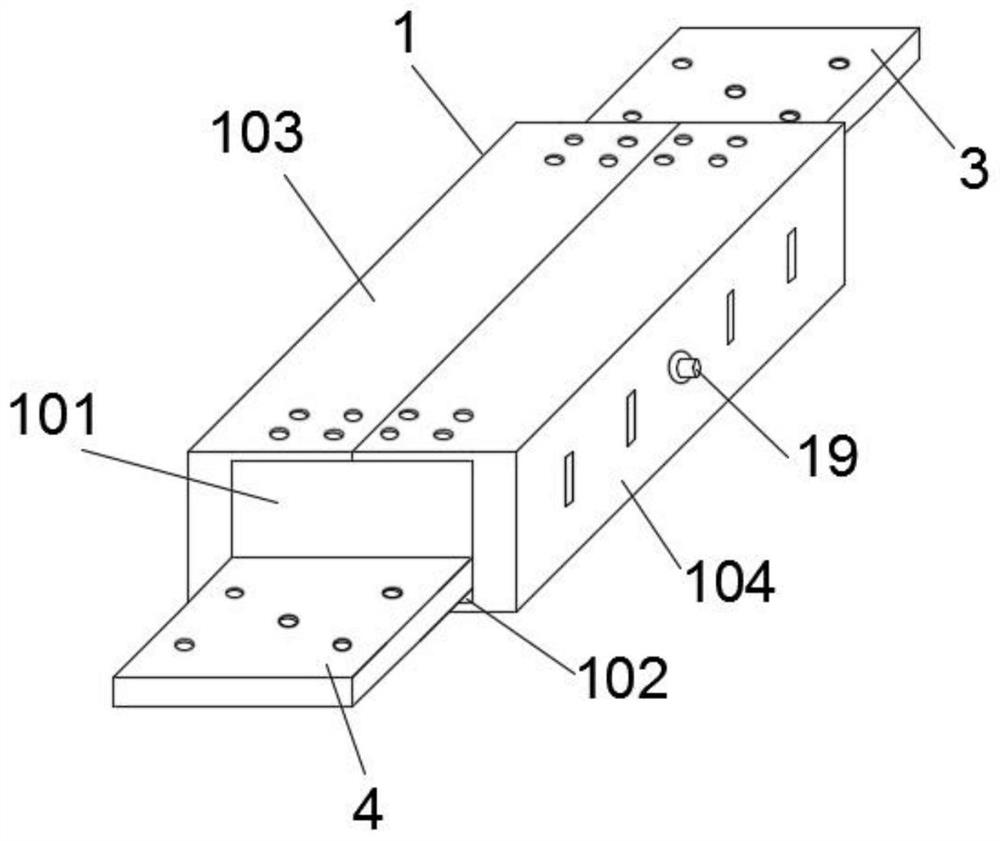

[0019] Such as figure 1 , the casing 1 of the rotatable reduction friction composite metal damper includes a top plate 101, a bottom plate 102, a left side plate 103 and a right side plate 104, which are fixed together by bolts. One end of the upper sliding guide rod 3 and one end of the lower sliding guide rod 4 extend out of the housing 1 . During use, one end of the upper sliding guide rod 3 and the lower sliding guide rod 4 protruding from the housing is fixedly connected with the structure requiring energy dissipation and shock absorption through bolts.

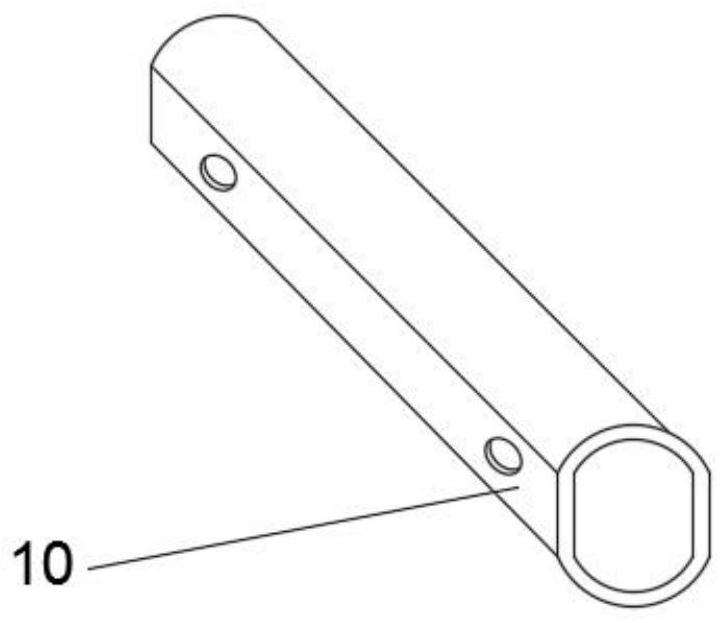

[0020] Such as Figure 2-4 , the friction plate one 7 is bolted to the base plate 102, and the bottom of the lower sliding guide rod 4 is bolted to the friction plate two 8. The lower sliding guide rod 4 fixedly connected with the friction plate two 8 is placed on the base plate 102 fixedly connected with the friction plate one 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com