Hydrogen replacement system

A technology for hydrogen and gas cylinders, applied in pipeline systems, measuring devices, fixed-capacity gas storage tanks, etc., can solve problems such as strong hydrogen leakage, short implementation period, and gas cylinder detection methods that cannot meet the detection requirements of hydrogen storage cylinders. Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

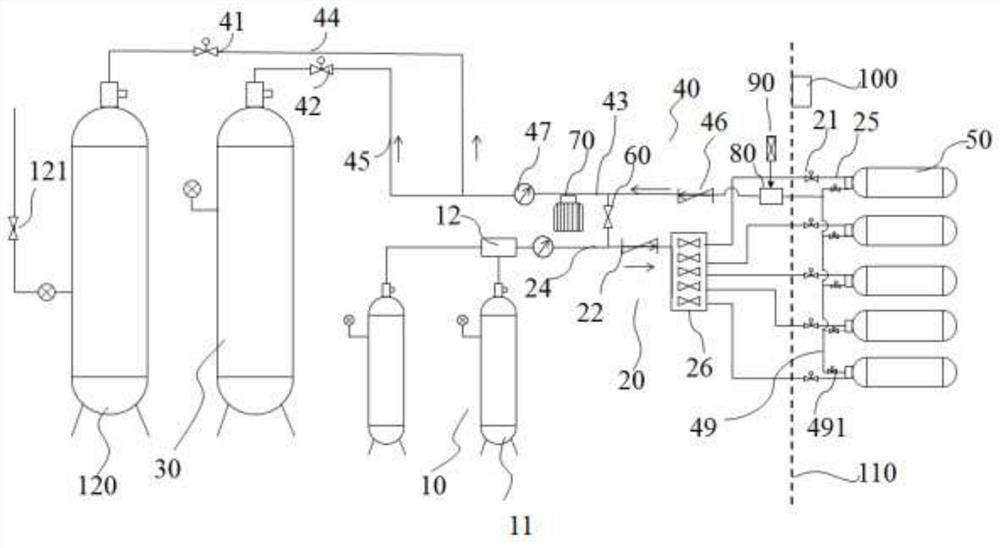

[0030] Such as figure 1 As shown, a hydrogen replacement system includes: a gas storage unit 10, storing nitrogen used to replace hydrogen in a gas cylinder 50; an inflation pipeline 20, used to connect the gas storage unit 10 and the gas cylinder 50, and the inflation tube A charging valve 21 is provided on the road 20; a hydrogen recovery unit 30 is used to recover the hydrogen in the gas cylinder 50; an exhaust pipeline 40 includes a first exhaust branch and a second exhaust branch; One end of the gas branch is connected to the gas cylinder 50, and a first valve 41 is provided on the first exhaust branch; the second exhaust branch connects the hydrogen recovery unit 30 and the gas cylinder 50, and the first exhaust branch A second valve 42 is provided on the second exhaust branch.

[0031] The hydrogen replacement system of this embodiment solves the current gap in the detection of the vehicle-mounted compressed hydrogen cylinder 50 in the laboratory. It can also be recyc...

Embodiment 2

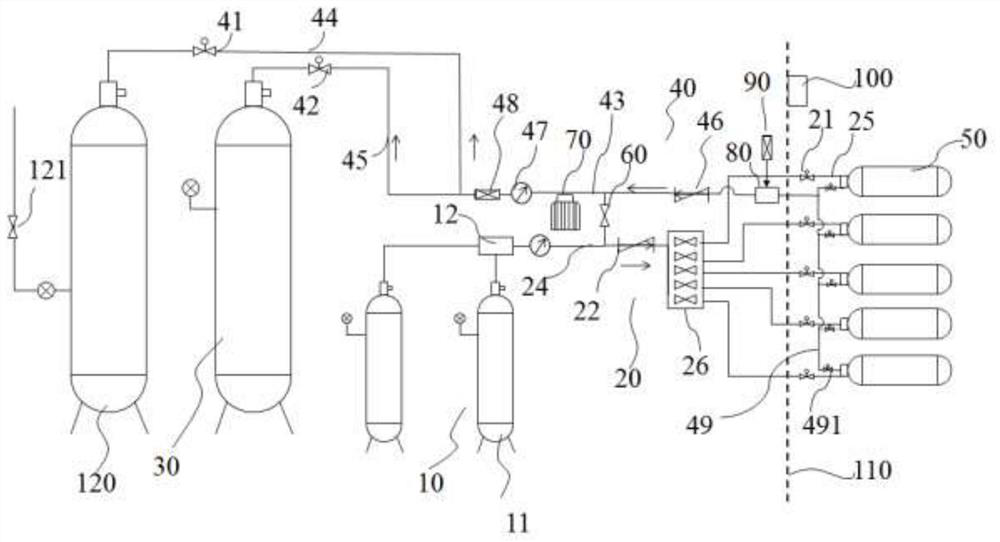

[0059] like figure 2 As shown, this embodiment is similar to the above embodiment in structure and working principle, the difference is that the exhaust main pipe 43 in this embodiment is also provided with a flame arresting device 48, which further improves the safety performance of the hydrogen replacement system in this embodiment , to avoid pipeline fire and explosion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com