Fire safety protection system for oil pipeline

A technology for safety protection and pipelines, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as oil pipeline damage, personnel injury, fire, explosion accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

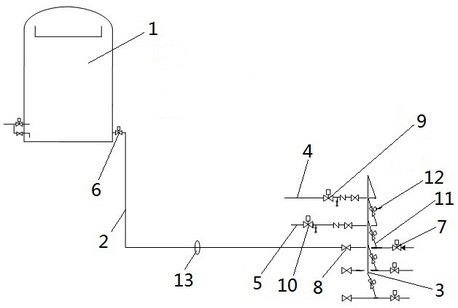

[0021] Such as figure 1 As shown, the oil pipeline fire safety protection system includes: receiving tank 1, oil pipeline 2, collection pipeline 3, nitrogen pipeline 4, fire pipeline 5; receiving tank 1, used for storing oil, oil pipeline 2 is connected to the receiving tank 1, and the oil pipeline 2 is provided with the root valve 6 of the receiving tank, the primary valve 8 of the boundary area, and the secondary valve 7 of the boundary area in sequence. The root valve 6 of the receiving tank is close to the bottom of the receiving tank 1, and the The primary valve 8 of the zone and the secondary valve 7 of the zone are close to the boundary of the pipeline.

[0022] The collection pipeline 3 is set at the boundaries of each pipeline, the collection pipeline 3 is connected to the oil pipeline 2 through the connecting pipeline 11, and the connection point between the connecting pipeline 11 and the oil pipeline 2 is located between the primary valve 8 in the boundary zone and ...

Embodiment 2

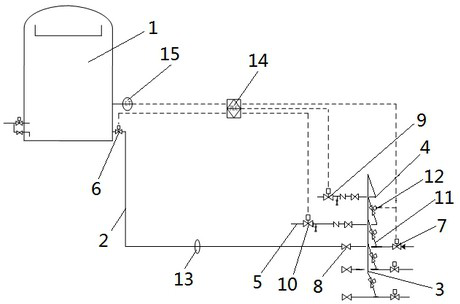

[0029] Such as figure 2 As shown, the present embodiment also includes a control device 14, a liquid level detection device 15, and an alarm device on the basis of Embodiment 1; the liquid level detection device 15 is located on the receiving tank 1 and is connected with the control device 14 for automatic detection The liquid level of the oil in the receiving tank 1.

[0030] The alarm device is located on the oil pipeline 2 and is connected with the control device 14, and is used for automatically sending out an alarm signal when the oil pipeline 2 leaks.

[0031] The control device 14 has the function of automatic remote control, which is used to receive the alarm signal sent by the alarm device, and issue instructions according to the alarm signal to control the opening or closing of the solenoid valves on the oil pipeline 2 and nitrogen pipeline 4; at the same time, it receives liquid level detection The signal sent by the device 15, and an instruction is issued accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com