Rolling bearing fault identification method based on the combination of spa-map and resnet

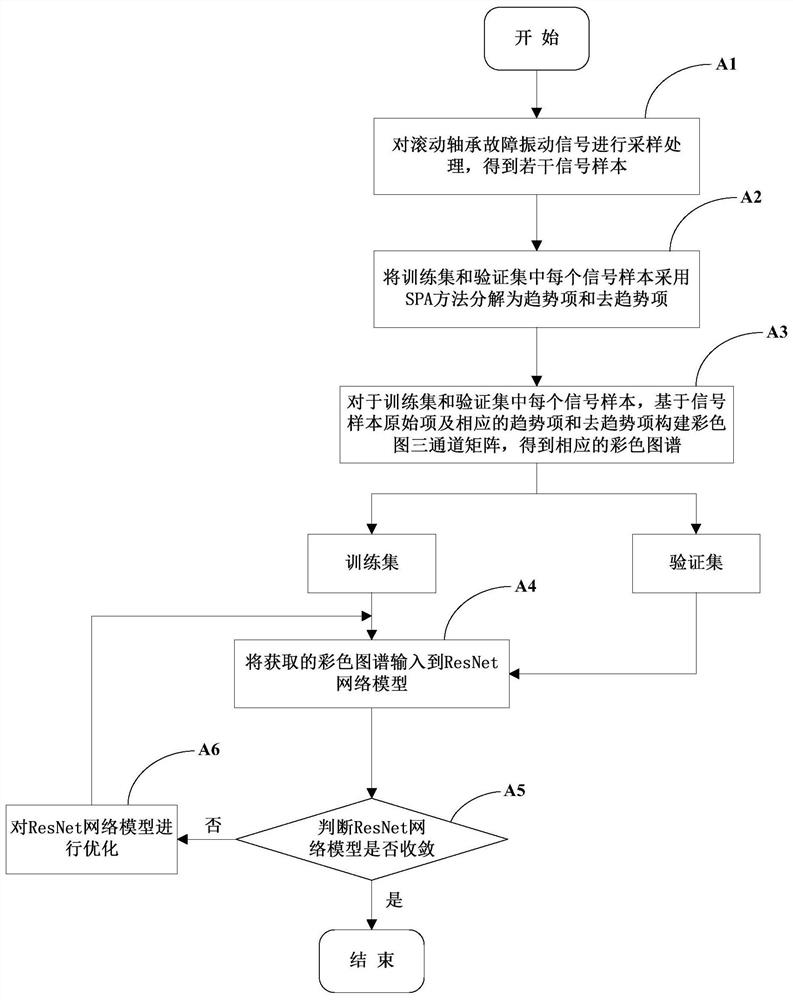

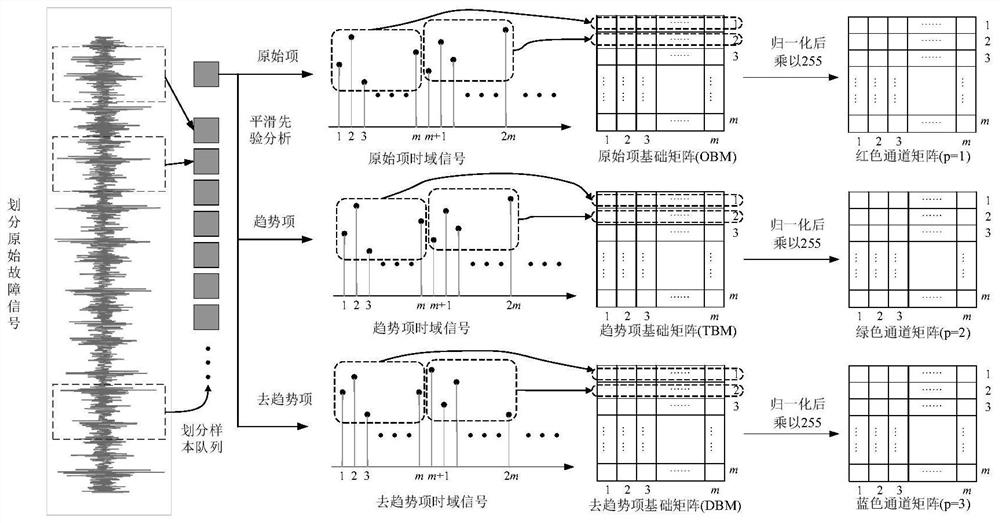

A rolling bearing and fault identification technology, which is applied in neural learning methods, character and pattern recognition, machine/structural component testing, etc., can solve problems such as large gradients, gradient dispersion, difficult network training, etc., to improve efficiency and accuracy, Simplify the preprocessing process and reduce the effect of component items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The experimental data used in the present embodiment is the 6205-2RS JME SKF deep groove ball bearing data set in the rolling bearing fault vibration signal opened by case Western Reserve University (CWRU) (SMITH W, RANDALL R. Rolling elementbearing diagnostics using case western reserve university data: a benchmarkstudy[ J]. Mechanical Systems and Signal Processing, 2015, 64-65(3): 100-131), its fault types are divided into inner ring fault, rolling element fault and outer ring fault, each fault is introduced by the EDM method single point fault, the fault diameter is 0.007inches, the load on each fault is 0, 1HP, 2HP and 3HP, and the data are used to construct a comparison with normal bearings under the same circumstances. See Table 1 for details.

[0082] Table 1 16 operating conditions under normal and 0.007 fault

[0083]

[0084]

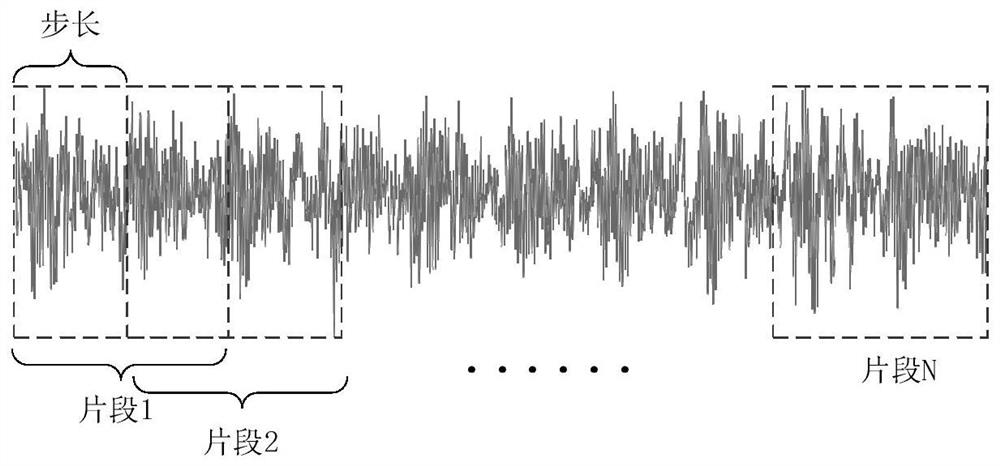

[0085] When dividing the data, according to the general training set, verification set and test set division principle, the data is di...

Embodiment 2

[0211] In order to further observe the failure identification method of the rolling bearing provided by the present invention in the classification of the fault site, and additionally select the degree of damage of 0.014inches and 0.021inches of data in accordance with the method given in Example 1 2 sets of 16 classification experiments (the specific working conditions are shown in Table 4). First of all, the data is divided into training sets, validation sets and test sets, and then the data in the training set and the validation set are used to train the ResNet network model (the same structure as in Example 1) in Steps A1-A6, and then the data in the test set are used to test the resNet network model trained according to steps S1-S4, and the experimental results and the experimental results under 0.007inches are recorded in Table 3. As can be seen from Table 3, the accuracy rate is more than 99% under all three types of damage, indicating that the method can effectively identi...

Embodiment 3

[0215] In order to further observe the performance of the rolling bearing fault identification method provided by the present invention in the classification of the degree of failure, all normal data and all the inner ring under load, the outer ring (6 o'clock direction) and the degree of damage of the rolling element, each set of 16 kinds of data to carry out 3 groups of experiments, wherein the inner ring condition as shown in Table 4, the outer ring (6 o'clock direction) and the rolling body working condition is similar to Table 4. First of all, the data is divided into training sets, validation sets and test sets, and then the data in the training set and the validation set are used to train the ResNet network model (the same structure as in Example 1) in Steps A1-A6, and then the data in the test set are used to test the resNet network model trained in steps S1-S4, and the experimental results are recorded in Table 5.

[0216] Table 4 16 operating conditions of normal and inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com