Ultrasonic fingerprint sensing chip, electronic equipment and manufacturing method

A technology for sensing chips and manufacturing methods, which are applied in the fields of acquiring/arranging fingerprints/palmprints, manufacturing microstructure devices, decorative arts, etc. The effect of density and fingerprint recognition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

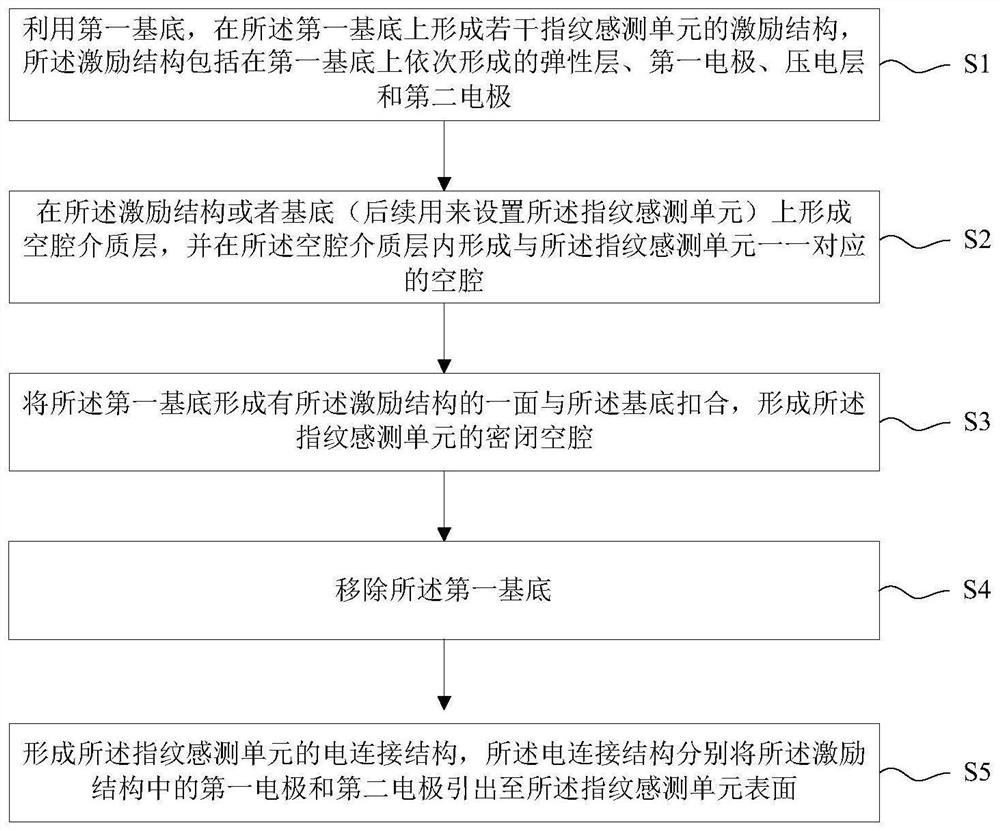

[0053] Figure 2A to Figure 2N It is a schematic cross-sectional structure diagram during the manufacturing process of the manufacturing method of the ultrasonic fingerprint sensing chip according to Embodiment 1 of the present invention. Refer to the following figure 1 with Figure 2A to Figure 2N , the manufacturing method of the ultrasonic fingerprint sensing chip according to Embodiment 1 of the present invention will be described.

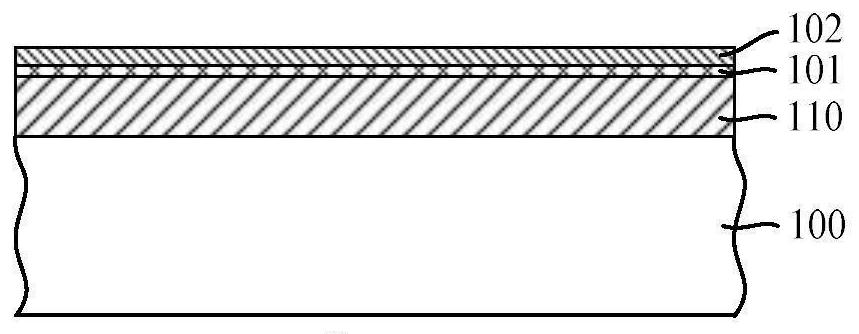

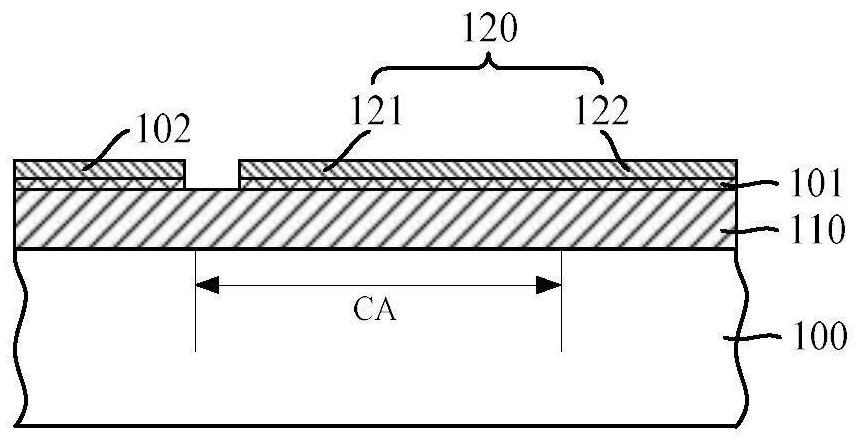

[0054] see Figure 2D The manufacturing method of the ultrasonic fingerprint sensing chip of this embodiment includes step S1, providing a first substrate 100, and forming a plurality of excitation structures 10 of fingerprint sensing units on the first substrate 100, and the excitation structure 10 is included in the first substrate 100. The elastic layer 110 , the first electrode 120 , the piezoelectric layer 130 and the second electrode 140 are sequentially formed on the first substrate 100 .

[0055] The material of the first substrate...

Embodiment 2

[0091] This embodiment relates to a manufacturing method of an ultrasonic fingerprint sensing chip. The main difference between this embodiment and the first embodiment lies in the method of forming the cavity.

[0092] This example is in Figure 2D The manufacturing method of the ultrasonic fingerprint sensing chip is further described on the basis of the process after the second electrode is formed. This embodiment may include the following: Figure 2A to Figure 2D The production process shown. Figure 3A to Figure 3D It is a schematic cross-sectional structure diagram during the manufacturing process of the manufacturing method of the ultrasonic fingerprint sensing chip according to the second embodiment of the present invention. The following main combination Figure 3A to Figure 3D The fabrication method of the ultrasonic fingerprint sensing chip of this embodiment will be described.

[0093] see Figure 3A Firstly, corresponding to the cavity area CA where the cavit...

Embodiment 3

[0099] This embodiment relates to a manufacturing method of an ultrasonic fingerprint sensing chip. The main difference between this embodiment and Embodiment 1 and Embodiment 2 lies in the method of forming the cavity.

[0100] This example is in Figure 2D The manufacturing method of the ultrasonic fingerprint sensor chip is further described on the basis of the process after the second electrode is formed, and this embodiment may also include the following: Figure 2A to Figure 2D The production process shown. Figure 4A to Figure 4E It is a schematic cross-sectional structure diagram during the manufacturing process of the manufacturing method of the ultrasonic fingerprint sensing chip according to the third embodiment of the present invention. The following main combination Figure 4A to Figure 4E The fabrication method of the ultrasonic fingerprint sensing chip of this embodiment will be described.

[0101] First, see Figure 4A , a cavity defining layer 107 is form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com