Tree barrier cleaning flying robot with suspended cutter system

A flying robot and cutting tool system technology, which is applied in the field of power transmission line tree barrier cleaning device, can solve the problems of difficult high-altitude tree barriers, chipping and cleaning, and low operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

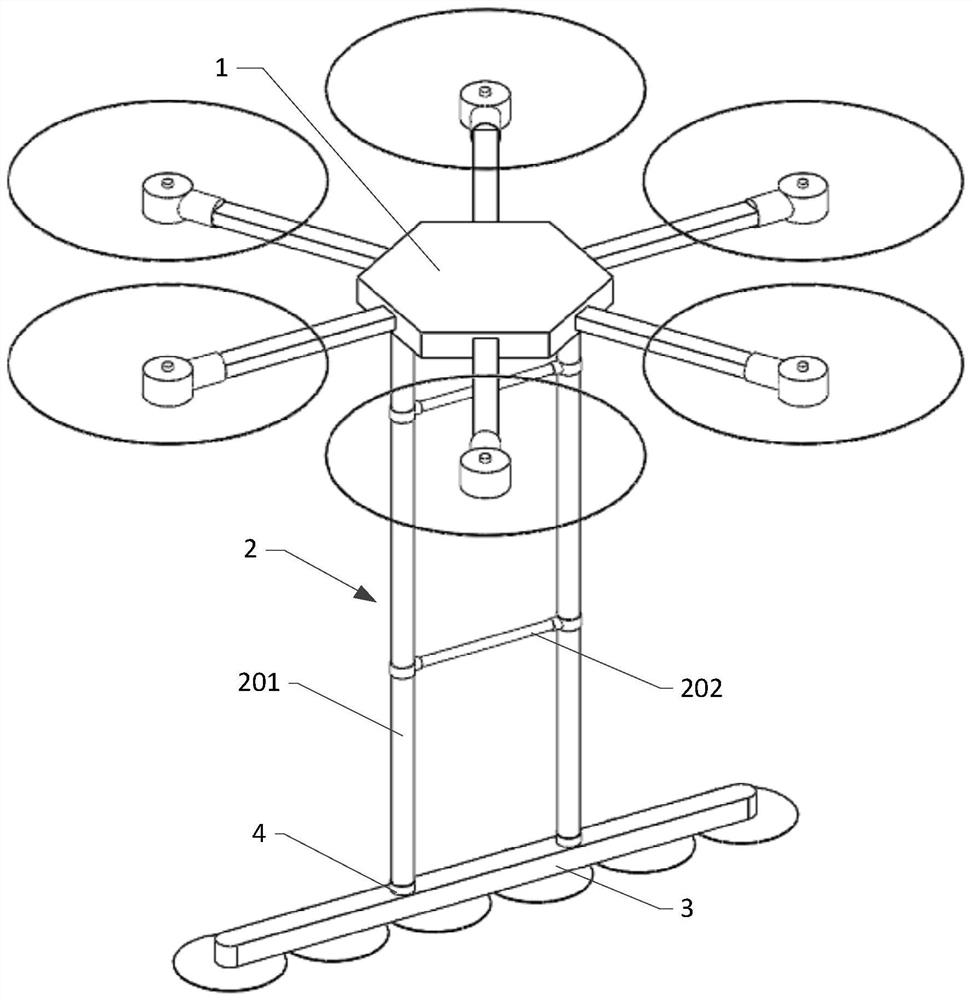

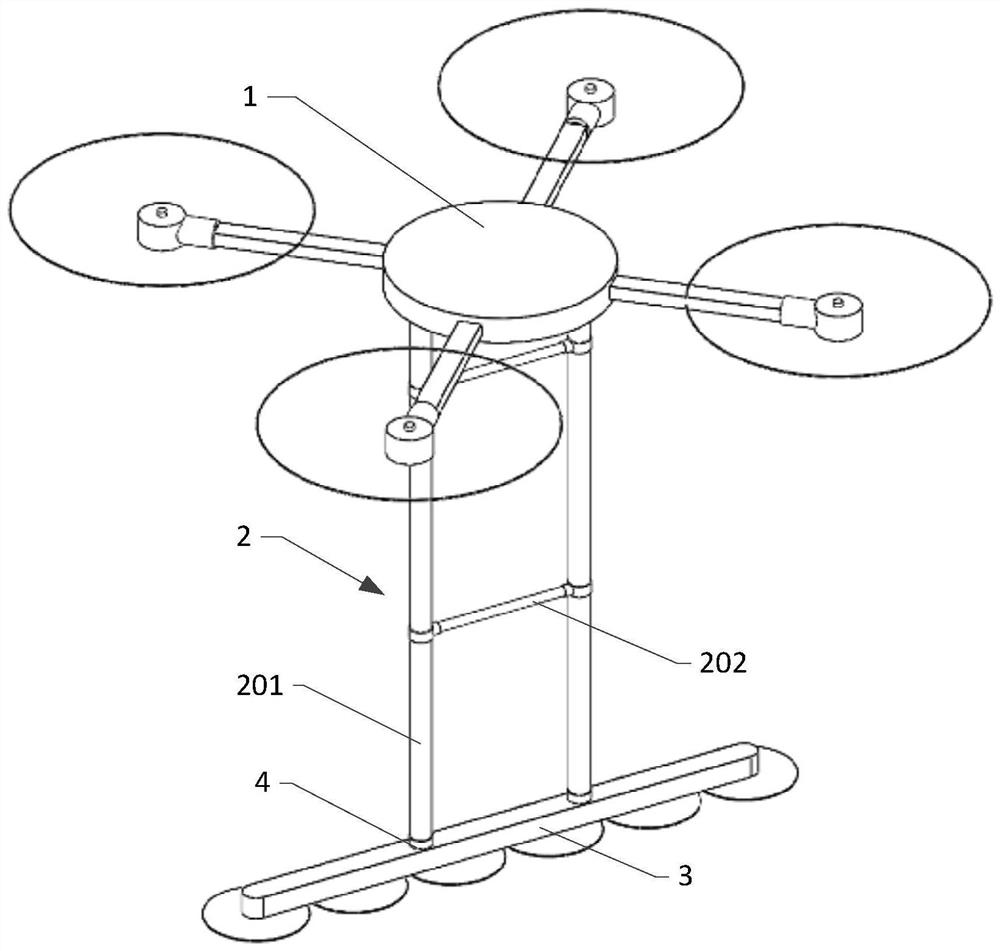

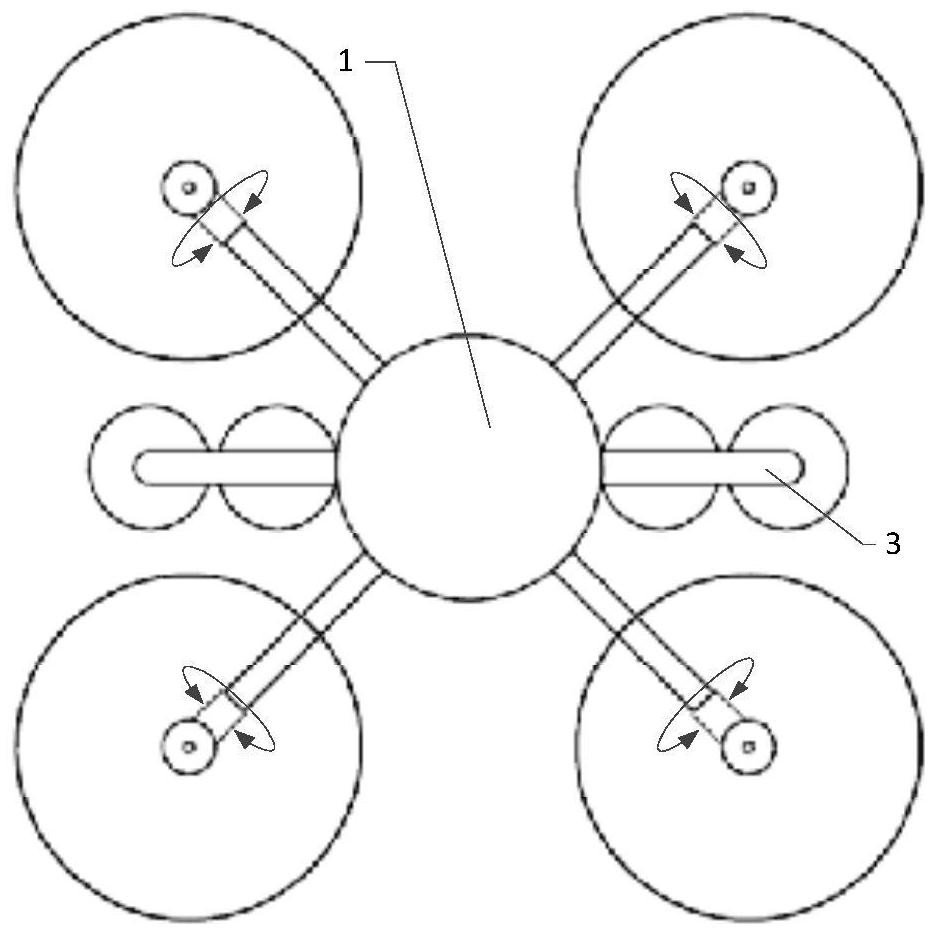

[0091] Embodiment 1: as Figure 1 to Figure 9 As shown, a tree obstacle clearing flying robot with a suspended tool system includes a flying platform 1, a suspension mechanism 2 connected to the bottom of the flying platform 1, and a tool system 3 connected to the bottom of the suspension mechanism 2; wherein, the suspension mechanism 2 is a fixed length The connecting rods, or variable-length telescopic suspension mechanisms, include L (L≥2) vertical rods 201 symmetrically arranged left and right, and transverse reinforcing beams 202 are arranged between adjacent vertical rods 201, and the tool system 3 is as follows: An array combination of M (M≥1) chainsaw components arranged in left-right geometric symmetry or mass symmetry.

[0092] Preferably, between the suspension mechanism 2 and the tool system 3 or between the flying platform 1 and the suspension mechanism 2, there is a decoupling device 4 that can hook or separate the two.

[0093] Preferably, the above-mentioned s...

Embodiment 2

[0135] Embodiment 2: as Figure 10 As shown, a tree obstacle clearing flying robot with a hanging tool system, the suspension mechanism 2 is a pulley type telescopic suspension mechanism: the vertical rod 201 includes a hollow tube 2203 that is continuously nested in H (H≥3) sections, and automatically The serial numbers from top to bottom are 1, 2, ..., H, and the upper end of the hollow tube 2203 of the i (1≤i<H) section is provided with an upper limit stopper that limits the movement overshoot of the hollow tube 2203 of the i+1 section when it contracts upwards. 2204, the lower end is provided with a lower limiter 2205 that restricts the movement of the i+1 section hollow tube 2203 when it is stretched downward; The upper end of the H-section hollow tube 2203 is provided with an upper limiter 2204, and the lower end is connected to the reciprocating saw system 3, and the upper limiter 2204 of the second section hollow tube 2203 is connected to the wire take-up device 2201 i...

Embodiment 3

[0138] Embodiment 3: A tree obstacle clearing flying robot with a hanging tool system. The vertical rod 201 of the suspension mechanism 2 described in Embodiment 1 is an electric push rod with a linear telescopic movement function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com