Automobile part machining and polishing device

A technology for spare parts and automobiles, which is used in grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of affecting the grinding effect, and it is impossible to determine whether the spare parts are polished, so as to improve the accuracy, improve the processing effect, prevent the The effect of too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

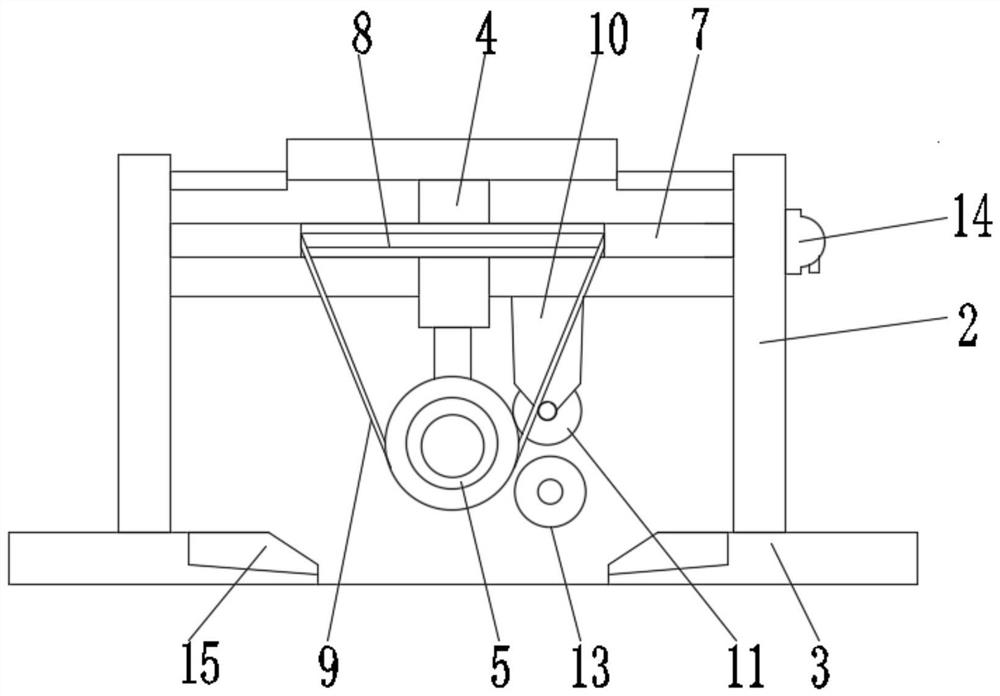

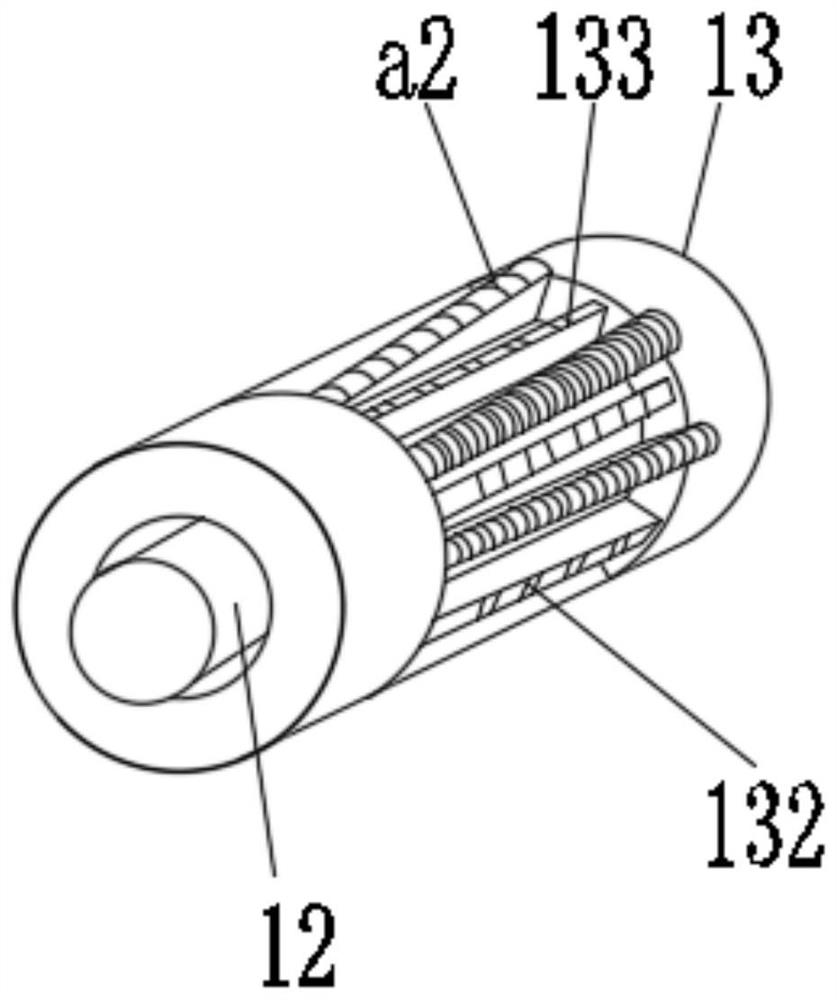

[0035] see Figure 1-3 and 6, the present invention provides a technical solution: a processing and polishing device for auto parts, comprising a base plate 1 and a fixed column 2, the left and right sides of the top of the base plate 1 are respectively fixedly connected to the bottom of the fixed column 2, and the fixed column 2 is opposite A laminate 3 is fixedly connected between one side, and the bottom of the laminate 3 is fixedly connected with a telescopic table 4, and the bottom of the telescopic table 4 is fixedly connected with a mounting rod 5, and the outer surface of the mounting rod 5 is provided with a spreading mechanism 6, and the fixed column 2. A fixed plate 7 is fixedly connected between the opposite sides and directly in front of the laminate 3. The outer surface of the fixed plate 7 is provided with a bar-shaped groove 8, and the inner surface of the bar-shaped groove 8 is slidably connected with a stabilizing mechanism 9. The outer surface of the plate 7...

Embodiment 2

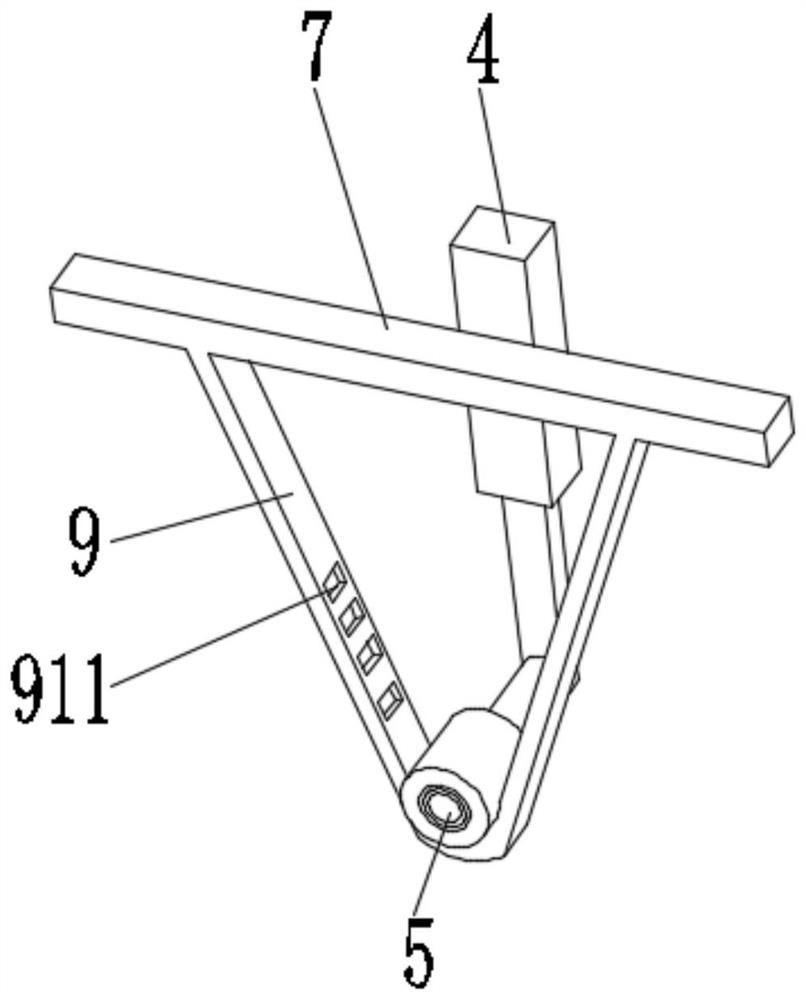

[0041] see figure 1 , 2 , 5, 7, the present invention provides a kind of technical scheme: stabilizing mechanism 9 comprises tension band 91, and the left end of tension band 91 is fixedly connected with the left side of strip groove 8 inside, and the right end of tension band 91 is connected with the inside of strip groove 8 Swipe right to connect.

[0042] The outer surface of the tension band 91 is evenly provided with a square groove 911, the inner surface of the square groove 911 is rotatably connected with a damping bearing 912, the outer surface of the damping bearing 912 is fixedly connected with a resistance ring 913, and the outer surface of the resistance ring 913 is evenly provided with an anti-slip sheet 914.

[0043] Stretching mechanism 6 comprises umbrella-shaped cover 61, and the inner side of umbrella-shaped cover 61 is fixedly connected with support rod 62, and one side of support rod 62 away from umbrella-shaped cover 61 is fixedly connected with pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com