A high-power load simulation system based on a cartridge valve and its application method

A high-power load and simulation system technology, applied in the field of simulation, can solve problems such as difficult to implement, unusable, complex structure, etc., and achieve the effect of simple structure, low cost, and elimination of forced flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

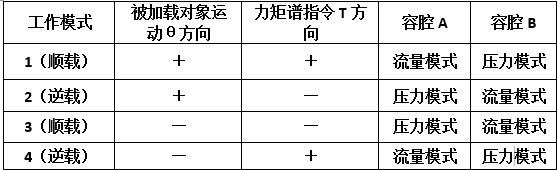

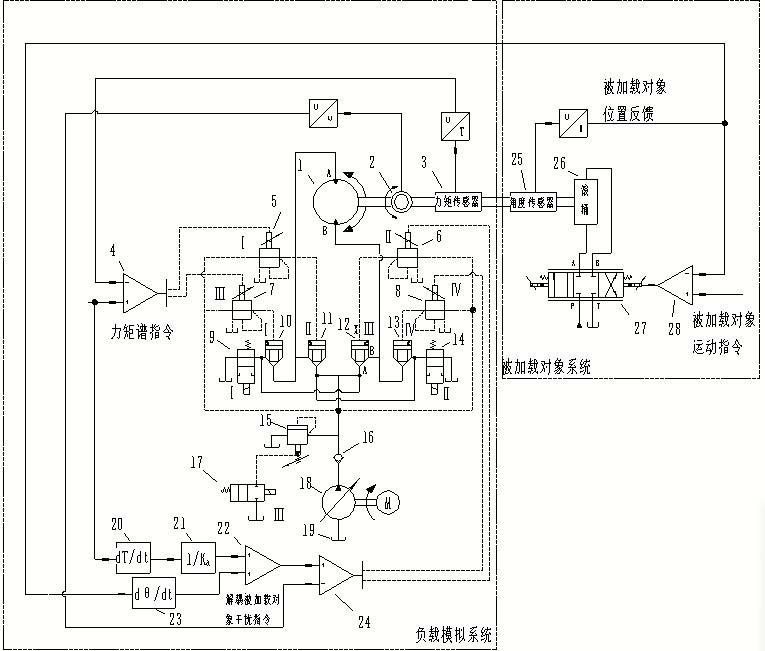

[0024] According to the motion angle θ of the loaded object and the direction of the torque spectrum command T, the working modes of the loading device can be divided into four types. Specifies to be loaded the object actuator ( figure 1 The center is the drum) as a reference, looking from right to left, the direction of movement direction θ and the direction of loading spectrum command T is positive in the counterclockwise direction.

[0025] Such as figure 1 As shown, when the direction of motion of the loaded object and the direction of the torque spectrum command are both positive, it is called working mode 1, the chamber A of the loading actuator works in the flow mode, and the chamber B works in the pressure mode; when the loaded object moves When the direction is positive and the direction of the torque spectrum command is negative, it is called working mode 2. The loading actuator A cavity works in the pressure mode, and the B cavity works in the flow mode; when the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com