Light-weight hub bearing unit and treatment method for pretreating laser additive

A laser additive, wheel hub bearing technology, applied in bearing components, wheel hubs, additive processing, etc., can solve the problems of increased cost, non-compliance with lightweight design, heavy parts weight, etc., and achieves the effect of ensuring the strength of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with accompanying drawing:

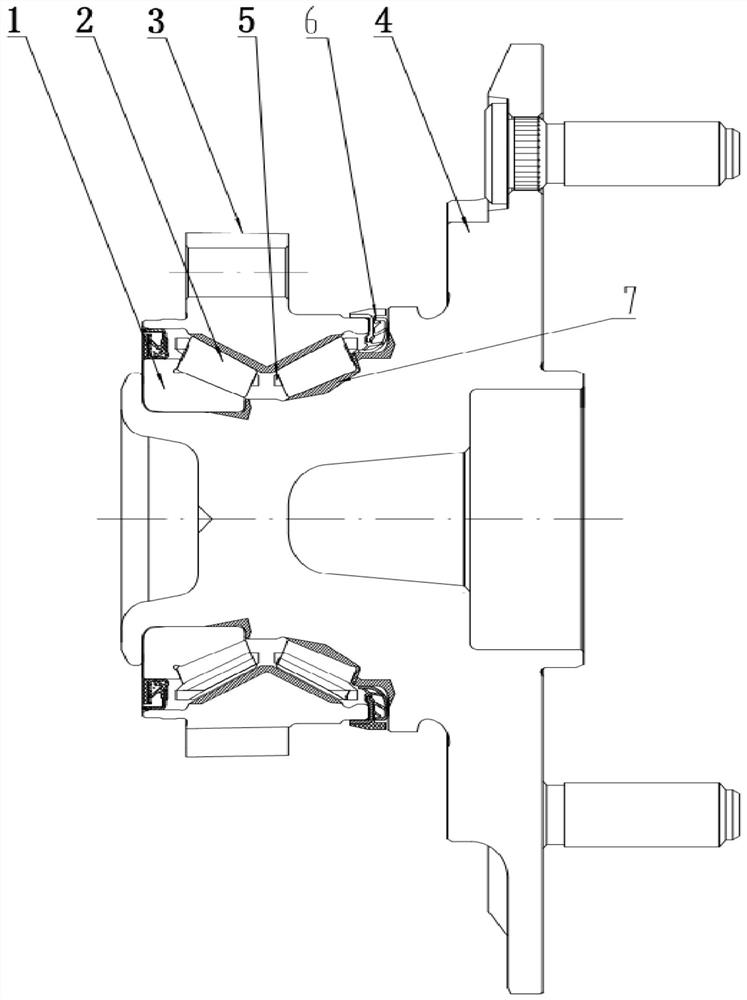

[0017] Embodiment: As shown in the accompanying drawings, the lightweight hub bearing unit of this pretreatment laser additive mainly includes bearing inner ring 1, bearing rolling body 2, bearing outer ring 3, flange plate 4, cage 5, seal Structure 6, the bearing inner ring 1 is installed on one end of the flange 4, and the root of the journal of the flange 4 is provided with an outer raceway, and the outer raceway and the inner raceway of the bearing inner ring 1 form a double-row raceway of the hub bearing unit , The bearing rolling body 2 is installed between the double row raceways, the bearing rolling body 2 is kept fixed by the cage 5, and the bearing rolling body 2 forms include balls, cylindrical rollers, tapered rollers, and needle rollers. A bearing outer ring 3 is installed on the outer side of the bearing rolling body 2 , and a sealing structure 6 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com