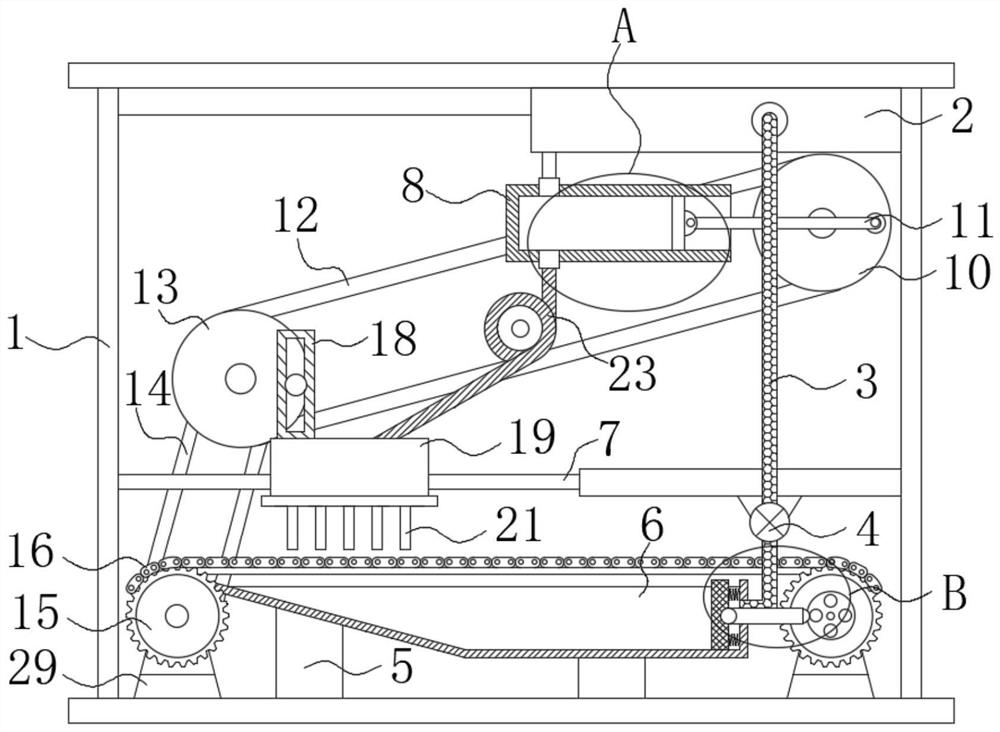

Combined chain wheel

A technology of sprockets and runners, applied in the direction of belts/chains/gears, lubricating parts, lubricating oil control valves, etc., can solve problems such as difficult cleaning, affecting environmental sanitation, and wasting lubricating oil, and achieve the effect of even oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

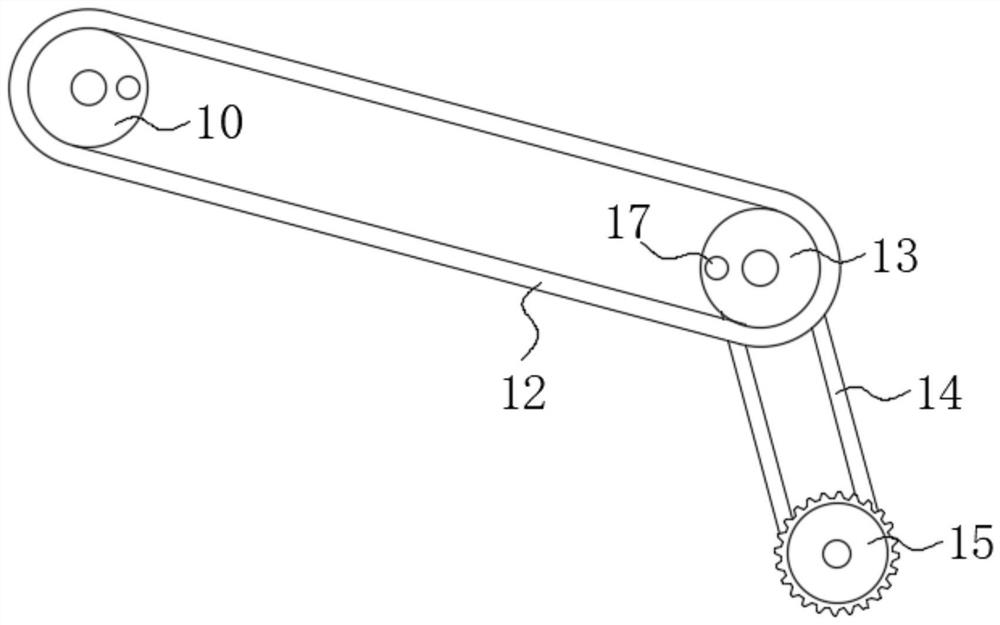

Embodiment approach

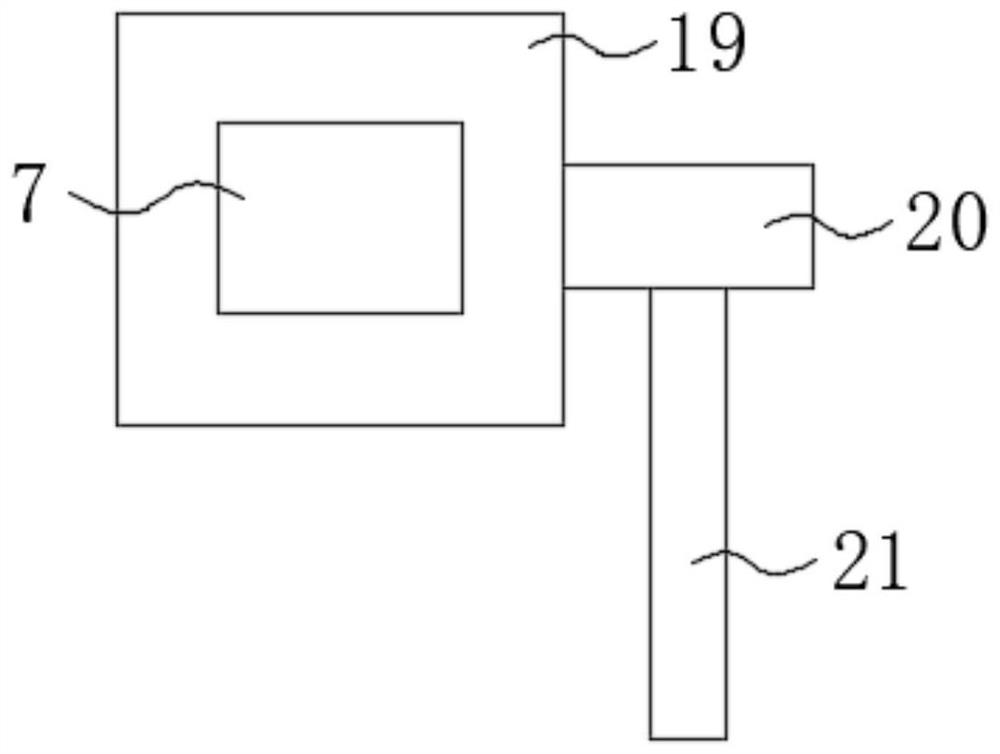

[0036] As an embodiment of the present invention, the oiling mechanism is composed of an installation frame 18, a movable block 19, a collection box 20, an oil injection nozzle 21 and a material guide hose 23, and the movable block 19 is slidably connected to the outer surface of the installation frame 18, The mounting frame 18 is fixedly connected to the upper end of the movable block 19, the outer wall of the round block 17 is slidably connected to the inner wall of the mounting frame 18, and the width of the round block 17 is equal to the width of the inner wall of the mounting frame 18, and the collecting box 20 is fixedly connected to the movable block. 19, the oil injection nozzle 21 is fixedly connected to the lower end of the collection box 20, and one end of the material guide hose 23 is fixedly connected to the upper end of the collection box 20, and the check valve body 22 is provided with two pieces, two check valves The bodies 22 are fixedly connected to the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com