Washable electronic tag integrated with RFID antenna and manufacturing method of washable electronic tag

An electronic tag and antenna technology, applied in the field of UHF RFID tags, can solve the problems of not being able to meet the washing management function, increase work and management costs, and affect wearing comfort, etc., to solve the problem of small coupling coefficient, not easy to miss detection, and ensure the safety of reading and writing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

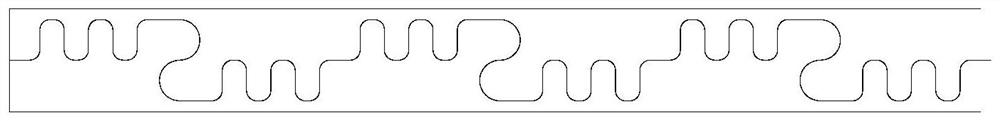

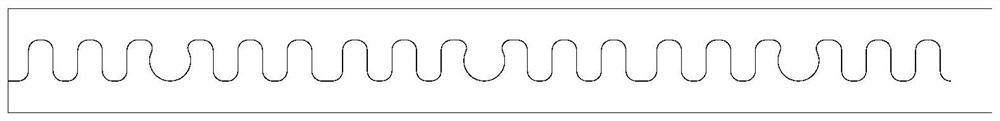

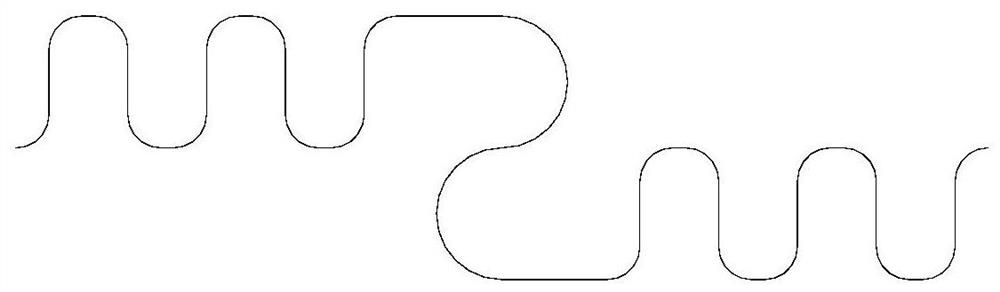

[0052]The electrical conductivity is 10000000s / m, which is designed to be intermediate a complete loop dipole label antenna 300 in an intermediate, a conductive fiber line having a relative magnetic permeability 100, a diameter of 50 μm, a resistor 30 Ω / m, a tensile strength 40N.Picture 1-1 ,2-13. Down 3, 4-1, 5, 6). The conductive wire and the label chip 100 of the label antenna 300 are attached to the polyester fabric in a polyester fabric. The tape line of the label antenna 300 uses a rope embroidery to attach it to the polyester fabric in accordance with a specific pattern trace, and the needle is adjusted to the polyester fabric, so that it maintains a certain geometric shape, in the ring 301 in the occasional antenna. The label chip 100 is placed, covering the cover layer 400 on the base fabric, and then the label the antenna is folded from the woven antenna unit, and the angle of the ring intersection is not directly in contact with the film chip.

[0053]In this embodiment,...

Embodiment 2

[0055]Example 2Picture 1-1 ,2-13, 4-1, 5, 6.

[0056]The electrical conductivity is 10000000s / m, and the relative magnetic permeability 100, the diameter of 50 μm, the resistor 30 Ω / m, the tensile strength 40N conductive fiber line is designed to be intermediate, in the middle of the antenna The label chip 100 is placed in the ring 301. The cotton fabric is a substrate 200, the label antenna 300 and the label chip 11 are attached to the cotton fabric.

[0057]In this example, a multi-conductive metal fiber stranded wire is made of label antenna 300. The cotton fabric is used as the substrate 200, which has extremely high softness, but in the water wash cotton fabric shrinkage, the conductive line contraction, the label working frequency band Variation, outside the 860 to 960 MHz band, the tag performance parameter change is greater than 3dB, and cannot be read normally.

Embodiment 3

[0058]Example III, referencePicture 1-1 ,2-13, 4-1, 5, 6.

[0059]The electrical conductivity is 10000,000s / m, which is relative to the magnetolence 100, a diameter of 50 μm, and a conductive fiber line 30Ω / m / m, is designed to be intermediate a complete loop dipole tag antenna 300. The tapered mixed textile is a substrate 200, the label antenna 300 and the label chip 100 are attached to the material of the polyester mixed textile. The label antenna uses a rope embroidery to attach it to the polyester blended fabric substrate 200, and the adjustment pin and direction are embedded to the flexible substrate 200, so that it maintains a certain geometric shape, in the middle of the antenna, 301 The label chip 100 is placed, covering the cover layer 400 on the base fabric, and then the label antenna 300 is folded from the woven antenna unit, and the angle of the ring is not directly in direct contact, and is separated by the film chip 100.

[0060]In this embodiment, a multi-stranded cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com