A kind of graphene enhanced thin film transistor and preparation method thereof

A technology of thin-film transistors and graphene films, applied in the field of sensors, can solve problems such as impact, and achieve the effects of reducing additional resistance, shortening distance, and improving electrical injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

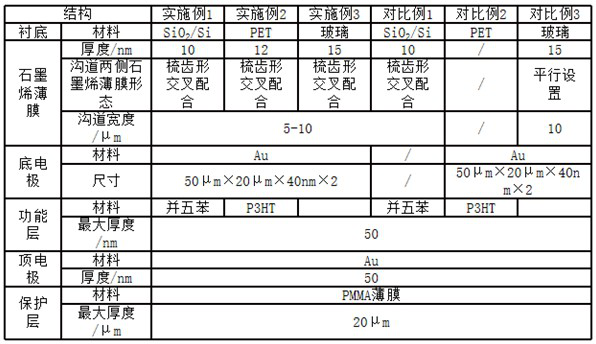

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples, and the examples are only preferred embodiments of the present invention, and are not intended to limit the present invention.

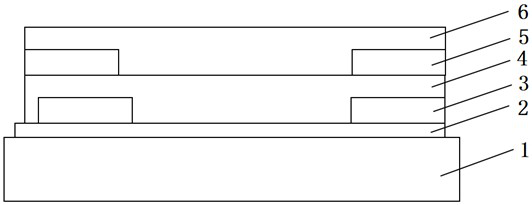

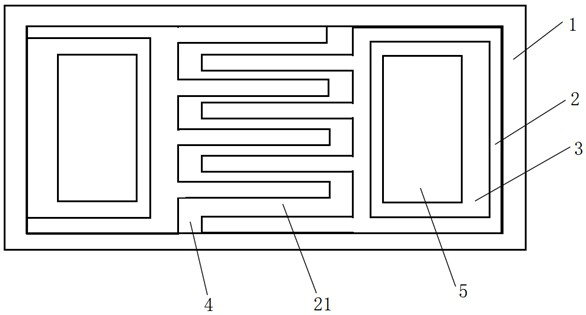

[0029] A preparation method of a graphene-enhanced thin film transistor, comprising the following steps:

[0030] S1. Graphene films are prepared on the substrate, and 1-2 layers of graphene films can be grown on the substrate in situ, or the graphene films grown on other substrates can be transferred to the target substrate by means of transfer;

[0031] S2. Graphene film patterning, the graphene film patterning can be vapor-deposited by means of leakage plate vapor deposition sacrificial layer, or photolithography is obtained after spin-coating photoresist on the surface of the graphene film, or nano-pressure Printing, screen printing and other graphic methods;

[0032] S3. The bottom electrode is prepared on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com