High frequency adhesive bonding

An adhesive, high-frequency technology, applied in the direction of adhesive heating, bonding method, adhesive, bonding shoe parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description is merely exemplary in nature and is not intended to limit the disclosure, application or uses.

[0032] The present invention provides a system for bonding a first layer of material to a second layer of material. The material layer may be selected from various material compositions. For example, the layer of material may be used to form or make a variety of different products, such as shoes or athletic shoes.

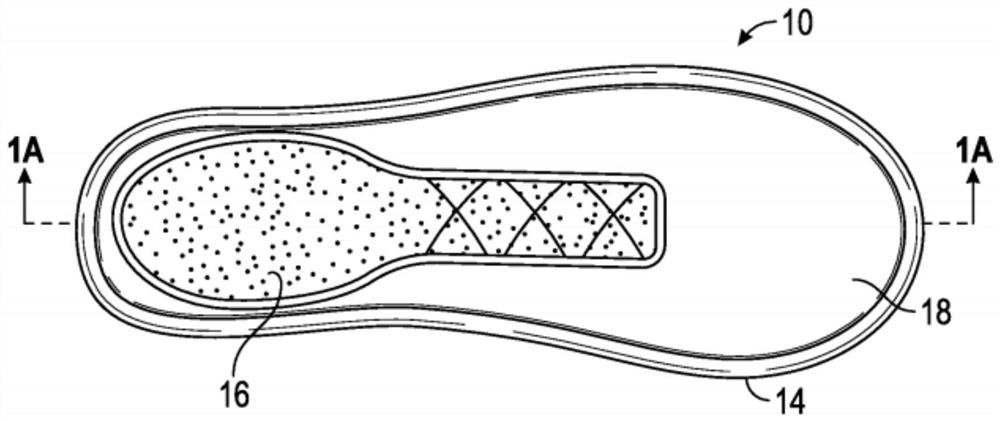

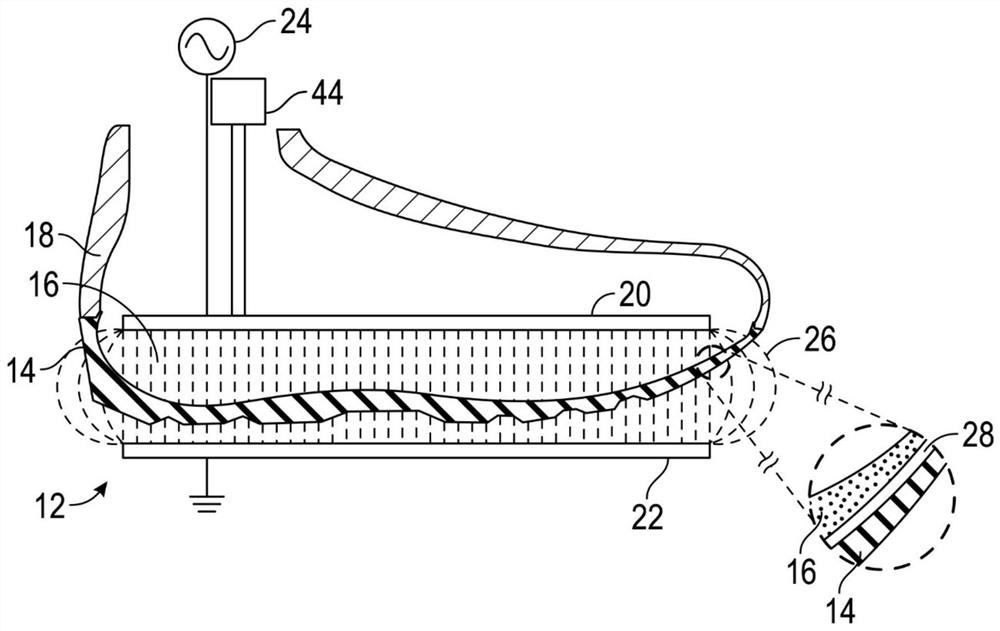

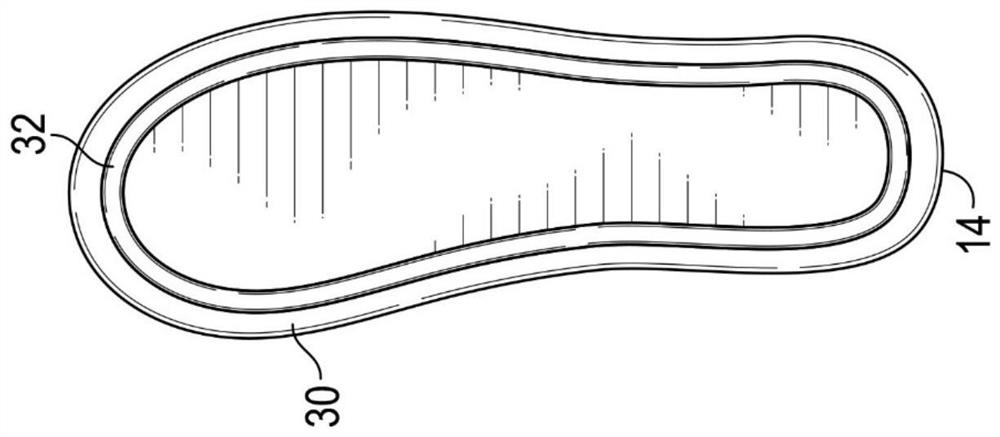

[0033] refer to figure 1 and figure 1 a, Top and side views, respectively, showing a shoe or athletic shoe 10 according to an aspect of the invention and a system 12 for bonding a first material layer to a second material layer. For example, athletic shoe 10 is a product that may be manufactured using system 12 for bonding a first layer of material to a second layer of material.

[0034] Athletic shoe 10 has an outsole 14 , a midsole 16 and an upper 18 . The outsole 14 can also be called a sole, and is the bottom part of the sports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com