Instant double-screw extrusion curing composite fruit and vegetable millet paste and production method thereof

A production method, the technology of millet paste, applied in the direction of food science, etc., can solve the problems of high energy consumption of gelatinization process, unfavorable industrial production and popularization and application, high production cost, etc., and achieves favorable promotion and utilization, low cost and high production cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

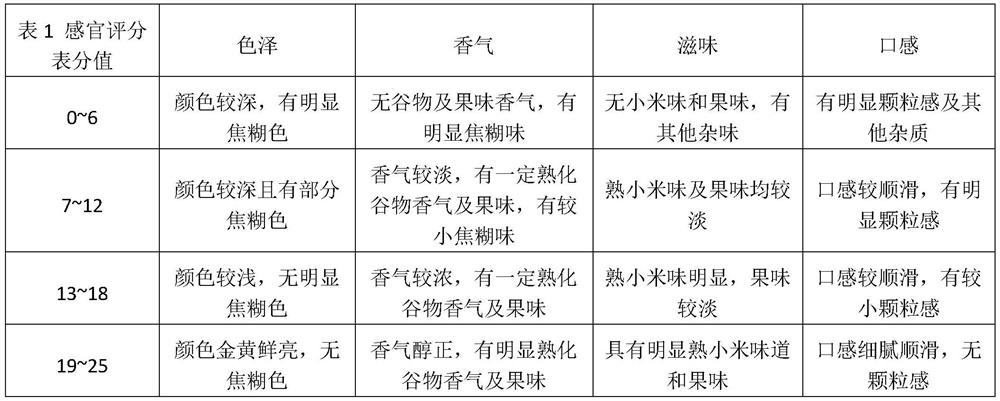

Examples

Embodiment 1

[0043] Taking a laboratory test as an example, a production method of ready-to-eat compound fruit and vegetable millet paste includes the following steps:

[0044] (1) 664g of millet flour and 166g of purchased corn flour are mixed and ripened;

[0045] (2) During curing, set the temperature of DS-56III twin-screw extruder heating and curing zone to be 60°C in zone I, 100°C in zone II, and 80°C in zone III, and the feeding speed is 90r / min;

[0046] (3) millet flour and corn flour after the ripening are dried;

[0047] (4) Drying is carried out by L3.5AB heat pump dryer, the setting temperature is 50°C, the drying time is 2h, and the pulverization is carried out after drying;

[0048] (5) use a vibrating ultrafine pulverizer to pulverize, and the pulverized powder is sieved;

[0049] (6) sieve with a 60-mesh sieve, and compound after the sieving is completed;

[0050] (7) When compounding, follow the ratio of 830g of millet and corn flour: 50g of pumpkin powder: 50g of malt...

Embodiment 2

[0055] Taking the pilot test as an example, a production method of ready-to-eat compound fruit and vegetable millet paste includes the following steps:

[0056] (1) 66.4kg of millet flour and 16.6kg of corn flour purchased carry out curing after mixing;

[0057] (2) During curing, set the temperature of DS-56III twin-screw extruder heating and curing zone to be 60°C in zone I, 100°C in zone II, and 80°C in zone III, and the feeding speed is 90r / min;

[0058] (3) millet flour and corn flour after the ripening are dried;

[0059] (4) Drying is carried out by L3.5AB heat pump dryer, the setting temperature is 50°C, the drying time is 2h, and the pulverization is carried out after drying;

[0060](5) use a vibrating ultrafine pulverizer to pulverize, and the pulverized powder is sieved;

[0061] (6) sieve with a 60-mesh vibrating screen, and compound after the sieving is completed;

[0062] (7) When compounding, follow the ratio of 83kg of millet and corn flour: 5kg of pumpkin ...

Embodiment 3

[0065] In the present embodiment, the temperature of ripening is adjusted, and other conditions are basically the same as in Example 1. Specifically, a method for producing instant-type composite fruit and vegetable millet paste comprises the following steps:

[0066] (1) 664g of millet flour and 166g of purchased corn flour are mixed and ripened;

[0067] (2) During curing, set the temperature of DS-56III twin-screw extruder heating and curing zone to be 80°C in zone I, 120°C in zone II, and 100°C in zone III, and the feeding speed is 90r / min;

[0068] (3) millet flour and corn flour after the ripening are dried;

[0069] (4) Drying is carried out by L3.5AB heat pump dryer, the setting temperature is 50°C, the drying time is 2h, and the pulverization is carried out after drying;

[0070] (5) use a vibrating ultrafine pulverizer to pulverize, and the pulverized powder is sieved;

[0071] (6) sieve with a 60-mesh sieve, and compound after the sieving is completed;

[0072] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com