3d orthopedic insole customization process

An insole and orthopedic technology, which is applied in the field of 3D orthopedic insole customization, can solve the problems of poor hygroscopicity of the insole, dampness in the shoe, poor comfort, etc., and achieves the effect of improving comfort, avoiding dripping of hot melt adhesive, and good hygroscopicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

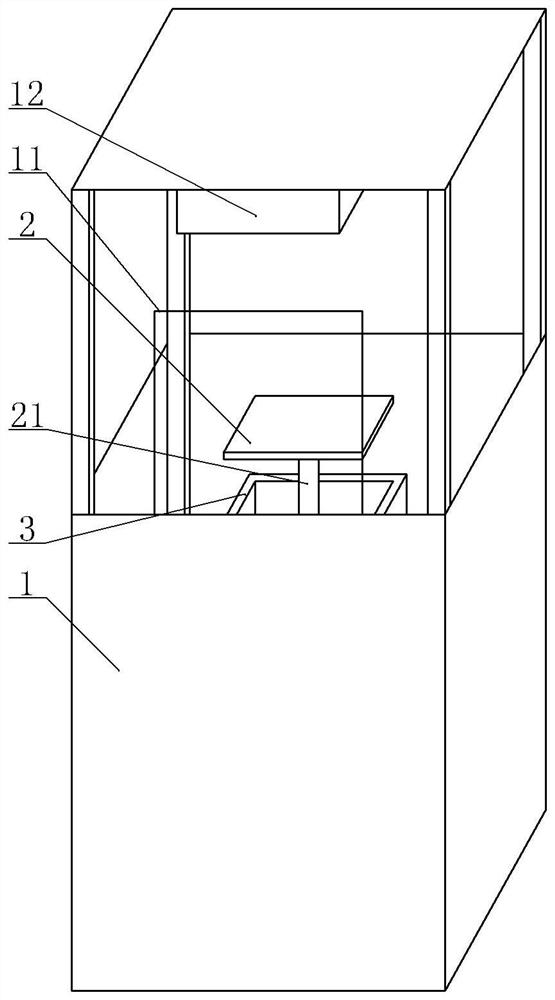

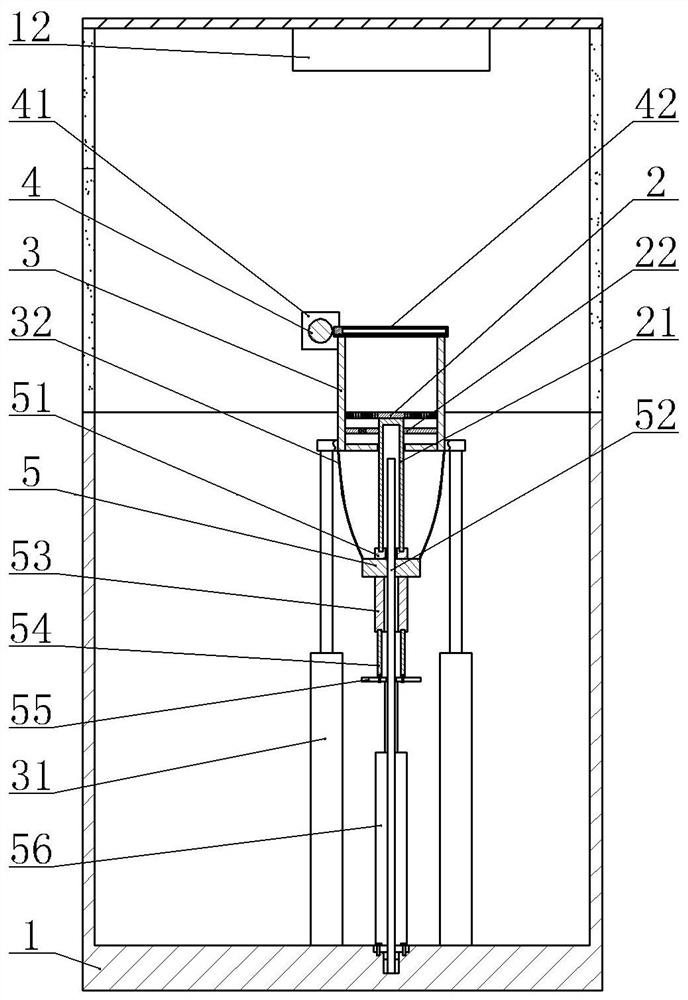

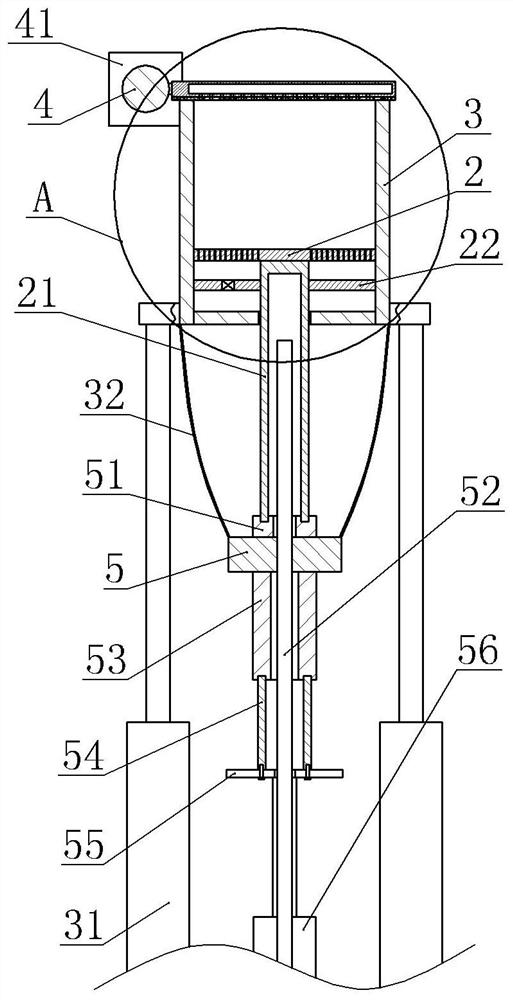

[0034] 3D orthopedic insole customization process, including the following steps:

[0035] Step 1. Generate a three-dimensional model of the foot based on the results of the imaging examination of the ankle, and determine a suitable insole surface and a three-dimensional model of the insole according to the three-dimensional model, and design several air holes through the insole on the three-dimensional model of the insole;

[0036] Step 2, import the 3D model of the insole into the 3D printer, print the insole through the 3D printer, and make the insole curved surface of the insole face up;

[0037] Step 3, using a hygroscopic sheet material as a cushion, and cutting the sheet material into gaskets whose length and width are respectively greater than the length and width of the insole;

[0038] Step 4, apply hot melt adhesive on the gasket, after the hot melt adhesive is solidified, turn the sealing cover to the state where the side with the hot air hole faces upward, then pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com