Metal bone needle

A technology of bone needles and metals, applied in internal bone synthesis, medical science, internal fixators, etc., can solve problems such as easy movement into joints, poor fixation effect, and limited screw holding force, so as to shorten the time of fracture fixation and facilitate surgery. Effects of cost reduction and shortened operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

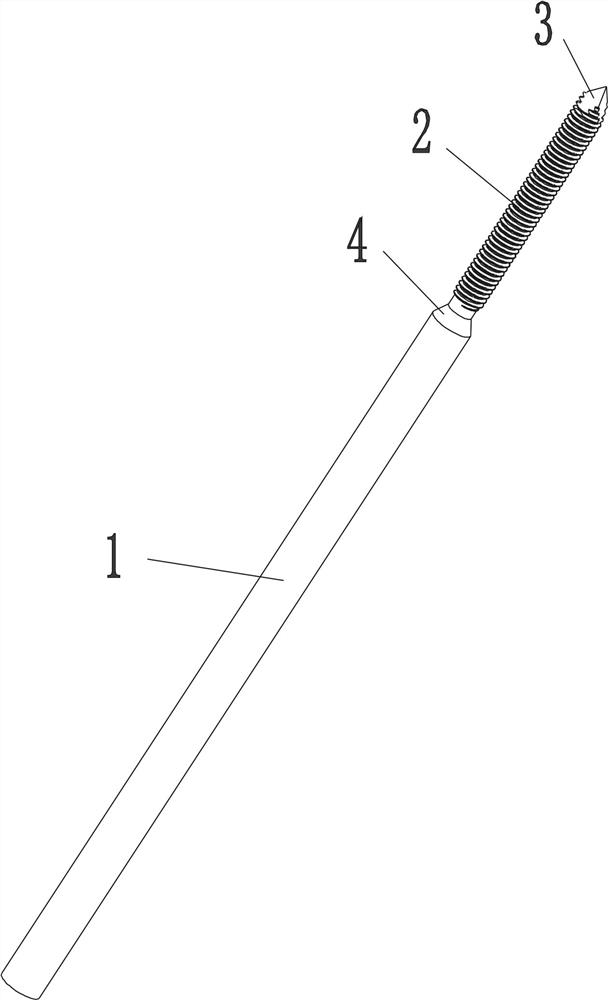

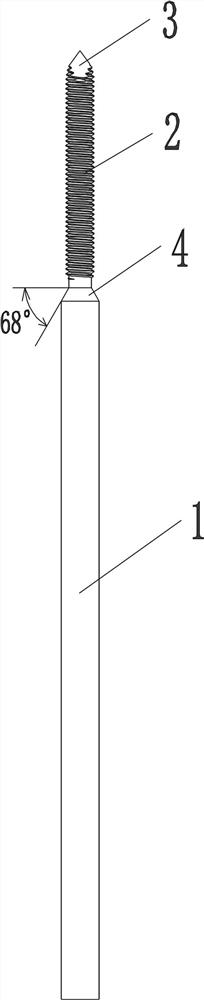

[0023] see Figure 1-Figure 2 , the present embodiment includes a stem part 1, a threaded part 2 and a head 3 of an integral structure, the thread of the threaded part 2 is a single-thread thread, the head 3 is a self-tapping drill bit, and the self-tapping drill bit is a triangular pyramid-shaped tip, and the stem part 1 The diameter is greater than the diameter of the threaded part 2, and a frustum-shaped shoulder 4 is provided between the rod part 1 and the threaded part 2, and the inclination angle of the shoulder 4 is 68°.

[0024] The shoulder 4 between the shank 1 and the threaded part 2 is similar to the screw tail of an ordinary screw, and if necessary, the size of the shoulder 4 can be increased by using a washer to facilitate compression. The threads of the threaded part 2 can be provided with lengths and diameters of different specifications, so as to be suitable for bone blocks of different parts and sizes.

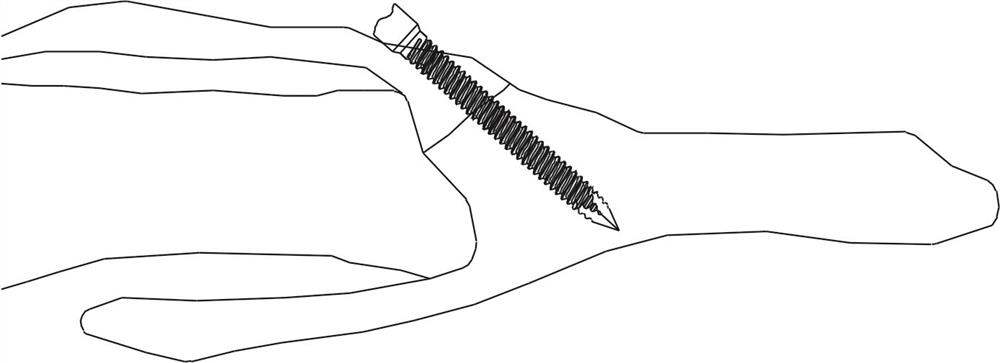

[0025] see Figure 3-Figure 4 When used in this embod...

Embodiment 2

[0027] see Figure 5-Figure 6 , the present embodiment includes a stem part 1, a threaded part 2 and a head 3 of an integral structure, the thread of the threaded part 2 is a double-thread thread, the head 3 is a self-tapping drill bit, and the self-tapping drill bit is a triangular pyramid-shaped tip, and the stem part The diameter of 1 is larger than the diameter of the threaded part 2, and a frustum-shaped shoulder 4 is provided between the rod part 1 and the threaded part 2, and the inclination angle of the shoulder 4 is 68°. The diameter of the threaded part 2 gradually decreases from the stem part 1 to the head 3, and the threads on the threaded part 2 gradually increase from the stem 1 to the head 3.

[0028] The shoulder 4 between the shank 1 and the threaded part 2 is similar to the screw tail of an ordinary screw, and if necessary, the size of the shoulder 4 can be increased by using a washer to facilitate compression. The threads of the threaded part 2 can be provi...

Embodiment 3

[0031] see Figure 9-Figure 10 , this embodiment This embodiment includes a rod part 1, a threaded part 2 and a head 3 with an integral structure, the thread of the threaded part 2 is a double thread thread, the head 3 is a self-tapping drill bit, and the self-tapping drill bit is a triangular pyramid-shaped tip , The diameter of the rod part 1 is greater than the diameter of the threaded part 2, a frustum-shaped shoulder 4 is provided between the rod part 1 and the threaded part 2, and the inclination angle of the shoulder 4 is 68°. A cutting edge 5 is provided on the threaded part 2 and the head 3, and a chip removal groove 6 is provided at the cutting edge 5, and the threads on the threaded part 2 gradually increase from the rod part 1 to the head 3.

[0032] The shoulder 4 between the shank 1 and the threaded part 2 is similar to the screw tail of an ordinary screw, and if necessary, the size of the shoulder 4 can be increased by using a washer to facilitate compression. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com