Lifting platform arranged on positioner

A technology of lifting platform and positioner, which is applied in the field of lifting platform, can solve the problems of checking the welding situation, and cannot adjust the welding torch position, current, voltage, welding speed in time, etc., and achieve the effect of simple processing, energy saving and transformation cost, and simple transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

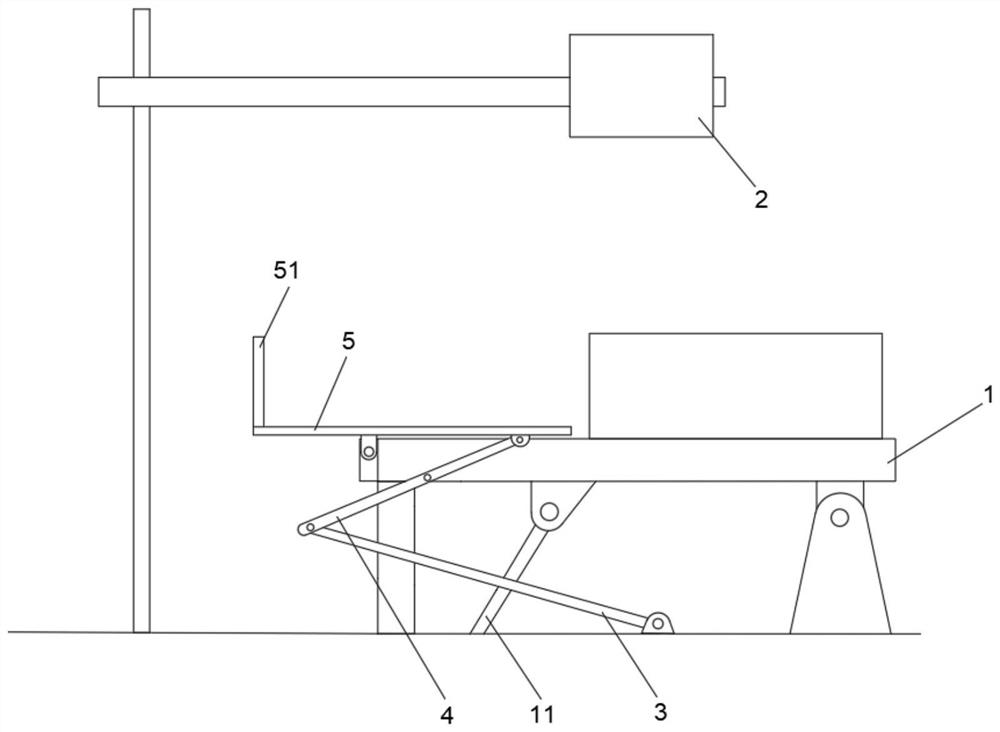

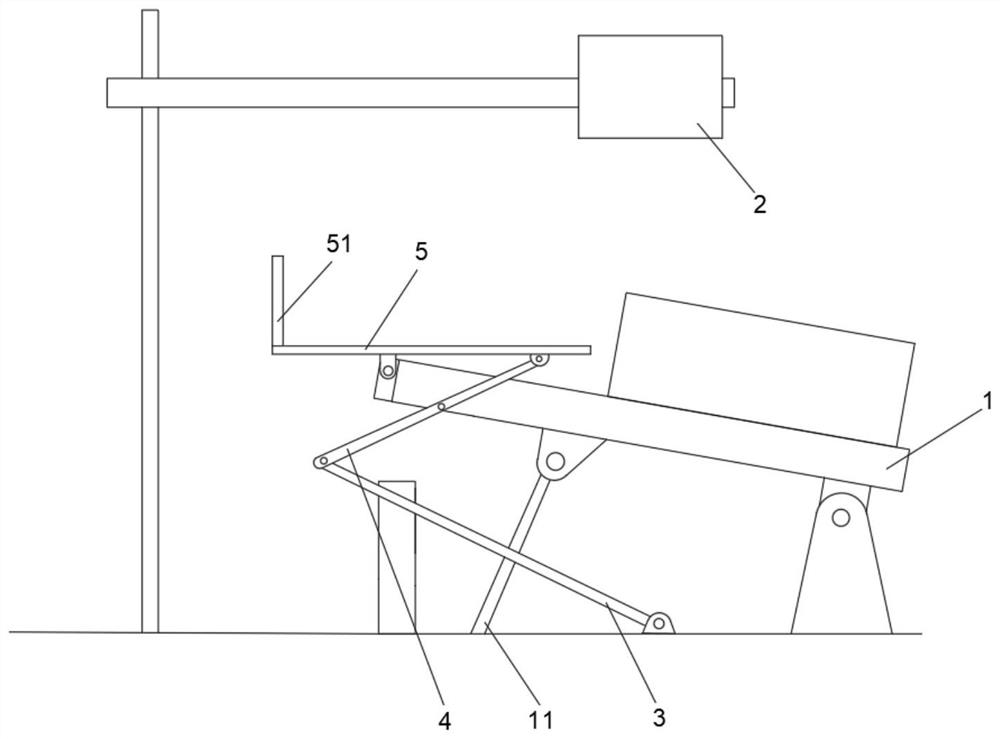

[0019] Such as figure 1 and 2 As shown, the lifting platform provided on the positioner provided in this specific embodiment includes a rotatable operating platform 5 connected to the positioner 1 and a plurality of liftable platforms for supporting the operating platform 5 to always meet the work requirements. Supporting mechanism, when the angle between the operating platform 5 and the horizontal plane is not greater than 5°, it meets the work requirements. The supporting mechanism is hinged to the lower end of the operating platform 5. Multiple supporting mechanisms are distributed on both sides of the positioner 1. 1 is raised or lowered to lift, when the positioner 1 is lifted or dropped, the operation platform 5 rotates around the connection point between the operation platform 5 and the positioner 1 under the action of the supporting mechanism to maintain the operation platform 5 always in line with the horizontal plane The included angle is not greater than 5°.

[00...

Embodiment 2

[0028] In this specific embodiment, another lifting platform provided on the positioner is provided. The lifting platform provided on the positioner provided in this specific embodiment is basically the same as the lifting platform provided on the positioner provided in Embodiment 1. The same, but the difference is: the support mechanism in this specific embodiment is an oil cylinder, and there are two oil cylinders. The hinge points of the positioner and the operation platform are not located on the same straight line. This setting realizes three non-collinear points supporting the operation platform to realize the stability of the operation platform. When the positioner is lifted or lowered, the two oil cylinders supporting the operation platform are simultaneously Action, extension or contraction, when the operation platform is lifted or dropped by the positioner, the operation platform rotates around the hinge point of the operation platform and the positioner under the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com