Convex grind sharpener capable of automatically changing grinding angle

A knife sharpener and angle technology, which is applied in the direction of grinding machines, abrasive belt grinders, grinding/polishing equipment, etc., can solve problems such as the difficulty of grinding clam blades, and achieve the effects of low cost, convenient operation, and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

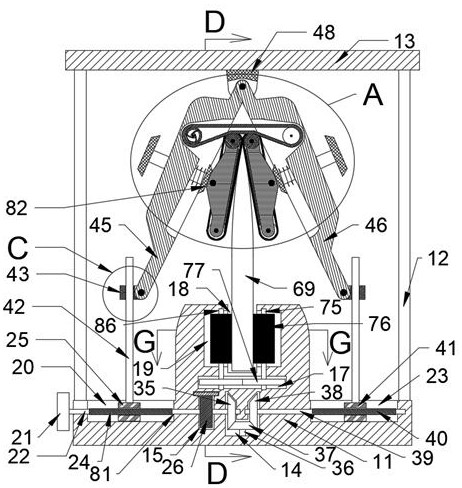

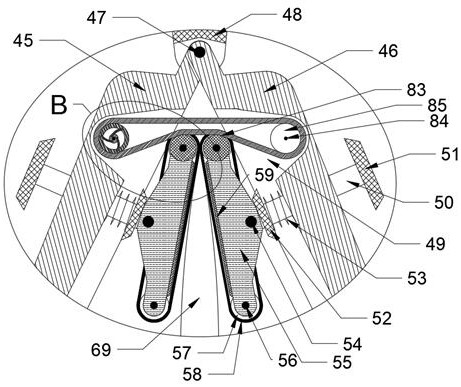

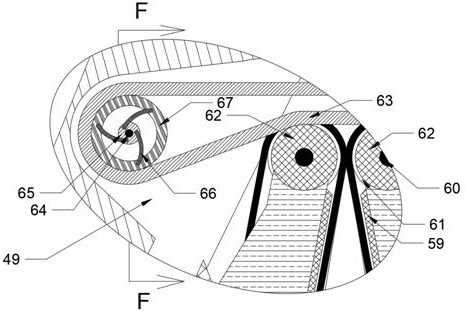

[0022] Combine below Figure 1-8 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0023] combined with Figure 1-8The clam blade sharpener with an automatically changing grinding angle includes a base machine 11, a top plate 13 and a right sharpening seat 46, and the base machine 11 is fixedly connected with four support rods 12 for supporting, The upper end of the support rod 12 is fixedly connected to the top plate 13, and the lower end surface of the top plate 13 is fixedly connected with a sharpening seat fixing head 48 at a suitable position, and the sharpening seat fixing head 48 is fixedly connected with a sharpening seat fixing shaft 47, A left sharpening seat 45 and a right sharpening seat 46 are respectively rotatably connected to the fixed shaft 47 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com