Side face pressing device

A technology of pressing device and cylinder, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of large welding production workload, difficult to guarantee processing requirements, high labor intensity, etc., and achieve reasonable component design and structure. Compact, well-structured and ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

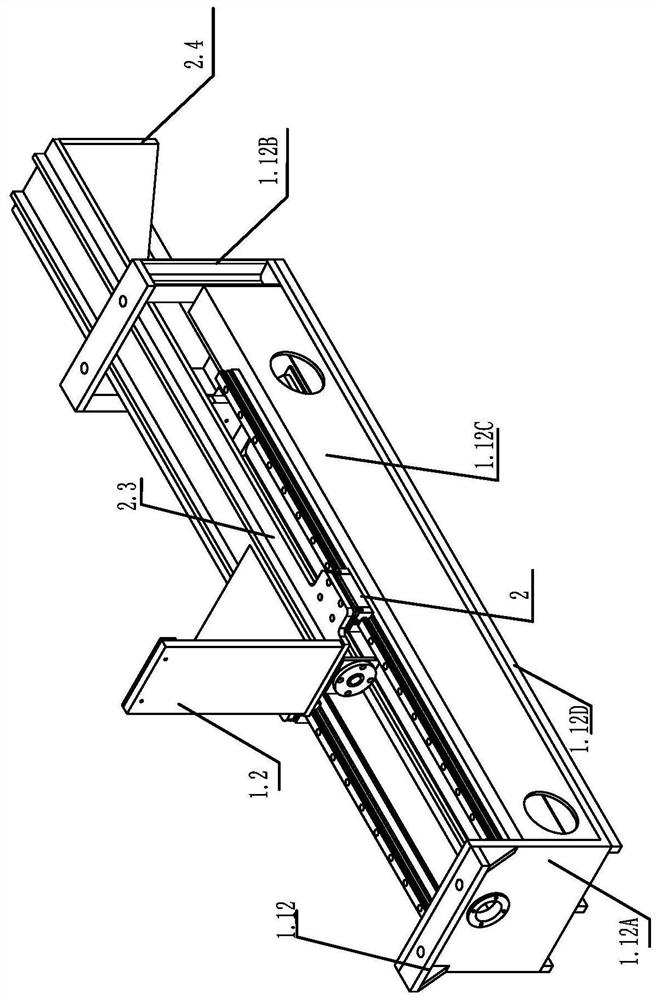

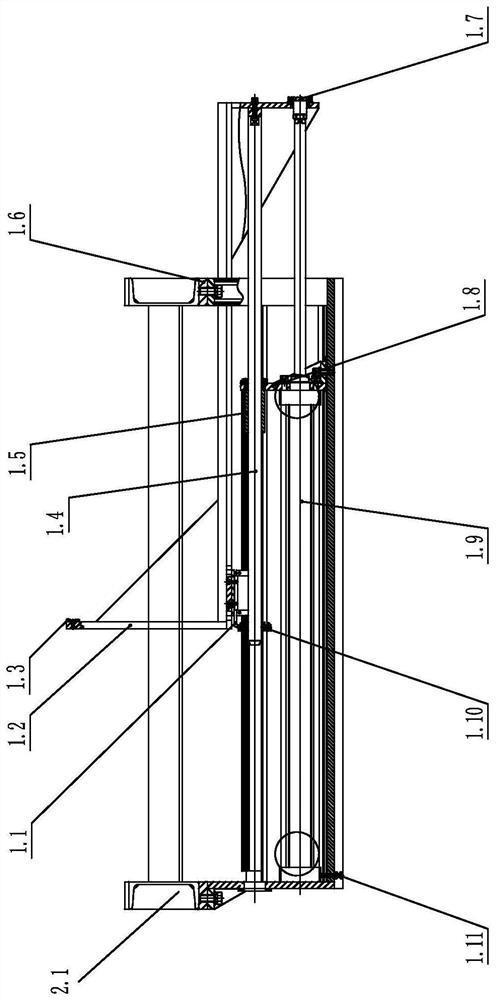

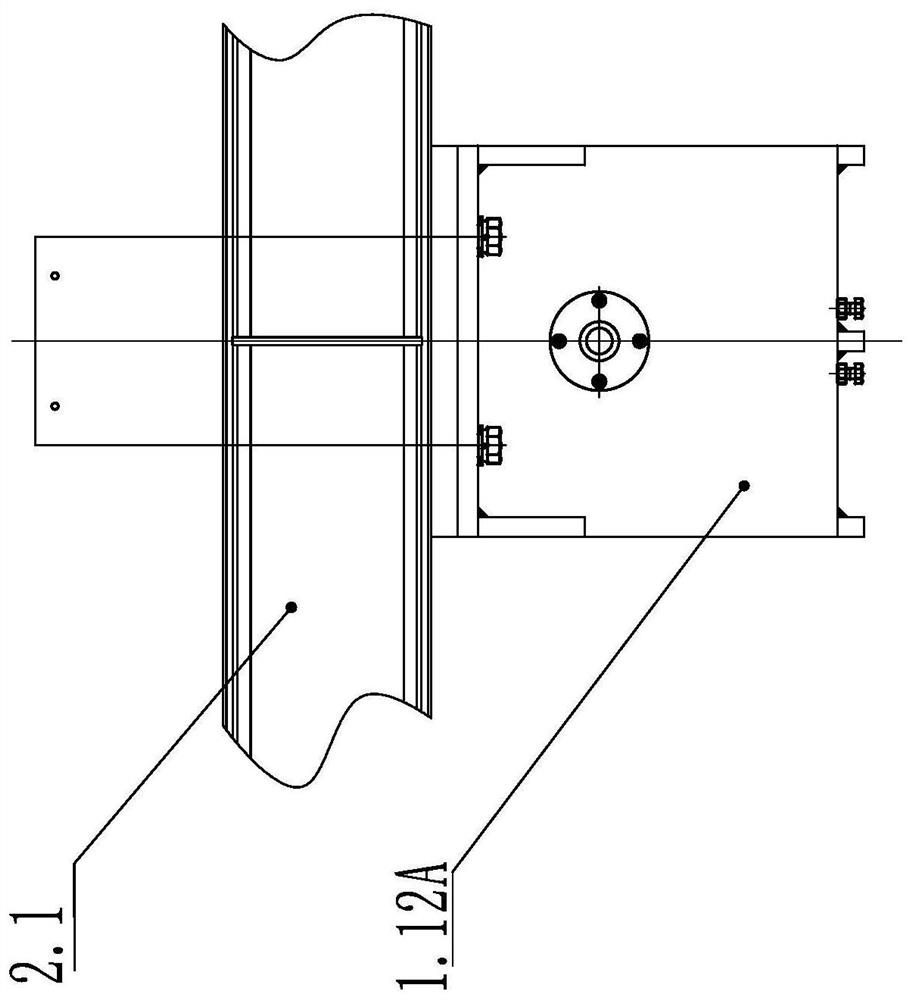

[0025] As shown in the figure: a side pressing device, the pressing device is fixed under the conveying track frame 2.1,

[0026] It includes a frame 1.12, a push frame 1.2, and a direct guide rail pair 1.13;

[0027] The frame includes a left frame body 1.12A and a right frame body 1.12B, as well as front and rear side plates 1.12C connecting the left and right frame bodies and a bottom plate 1.12D;

[0028] The linear guide rail pair 1.13 is respectively assembled on the front and rear side panels 1.12C, the linear guide rail pair 1.13 is slidably provided with a slider 2, the bottom of the push frame 1.2 is vertically provided with a connecting plate 2.3, and the bottom of the connecting plate is fixed to the slider 2 connect;

[0029] A pushing frame assembly is assembled in the frame.

[0030] The push frame assembly includes cylinder 1.9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com