Chemical fiber spinning and drying device

A drying device and chemical fiber technology, applied in the field of chemical fiber spinning machinery, can solve the problems of easy heat dissipation, inconvenient air circulation, inconvenient movement, etc., and achieve the effect of increasing thermal insulation effect, improving thermal insulation effect, and facilitating movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

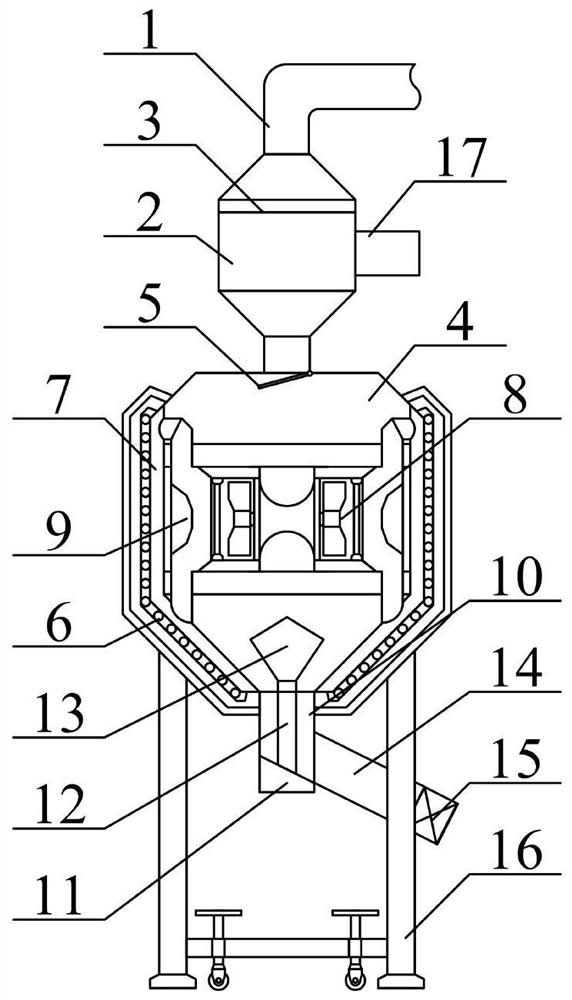

[0041] as attached figure 1 And attached figure 2 shown

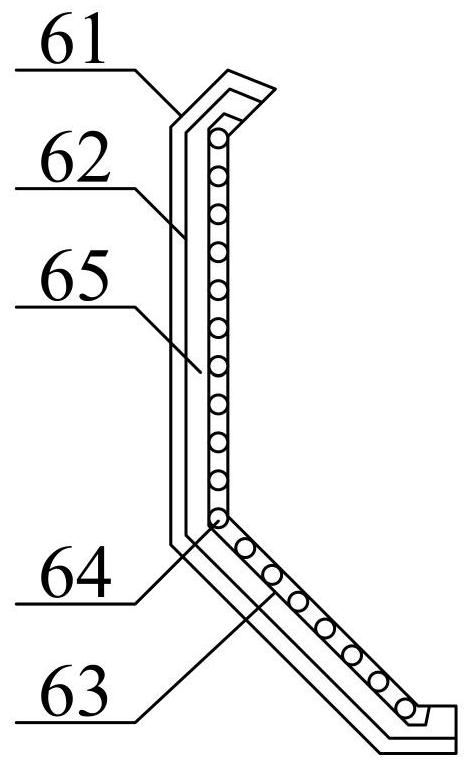

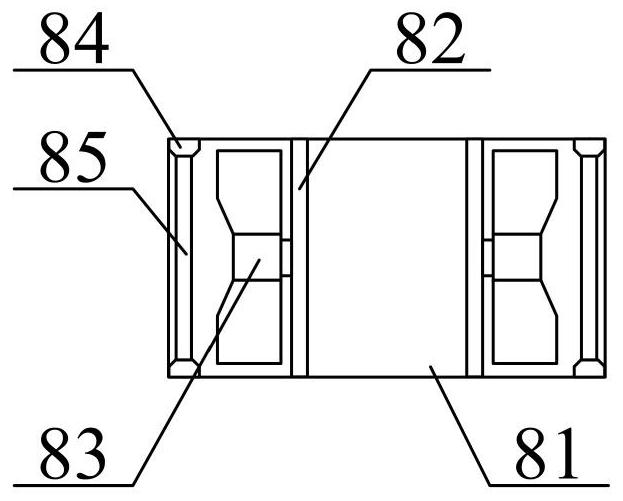

[0042]The present invention provides a chemical fiber spinning drying device, comprising a vacuum tube 1, a shunt tank 2, a mesh baffle 3, a feed bin 4, a vacuum suction valve 5, a side auxiliary heating insulation frame structure 6, a hot air flow equalizer 7, Hot air circulation supply rack structure 8, air circulation pipe rack structure 9, bottom conduit 10, fixed seat 11, connecting rod 12, material separator 13, outlet pipe 14, outlet valve 15, adjustable bracket structure 16 and feed pipe 17, The vacuum tube 1 is welded on the top of the shunt tank 2; the shunt tank 2 is welded on the top of the feed bin 4; the mesh baffle 3 screws are installed on the inside upper part of the shunt tank 2; the feed bin 4 Installed on the top of the adjustable bracket structure 16; the vacuum suction valve 5 is threadedly connected to the middle and upper part of the feed bin 4; the side auxiliary heating insulation frame stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com