Automatic decoking multi-layer sealing discharging ball valve with double scrapers

A multi-level, double-scraper technology, applied to the valve details, valve device, valve housing structure, etc., can solve the problems of easy wear of the valve seat and ball sealing surface, poor sealing performance, and short service life, so as to improve the sealing reliability , Sealing performance and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

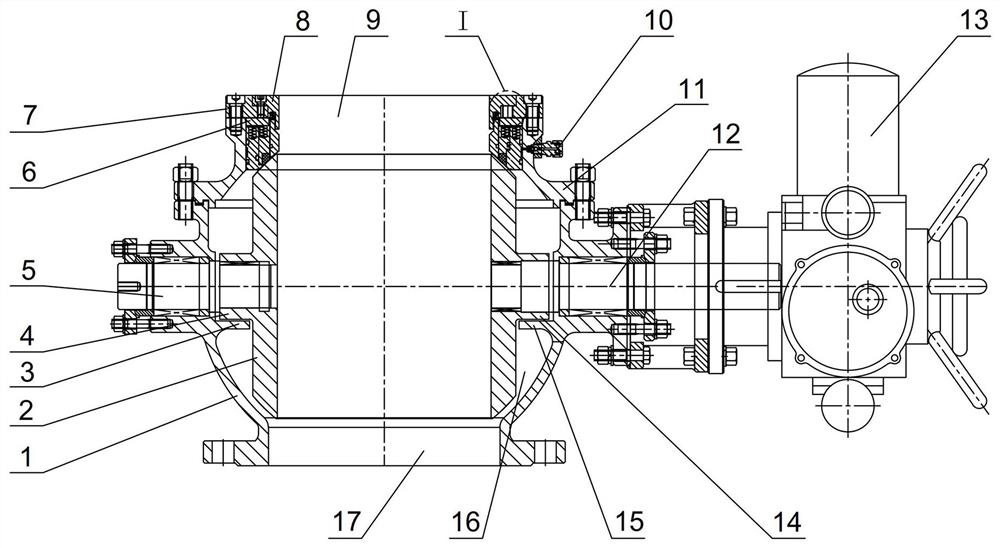

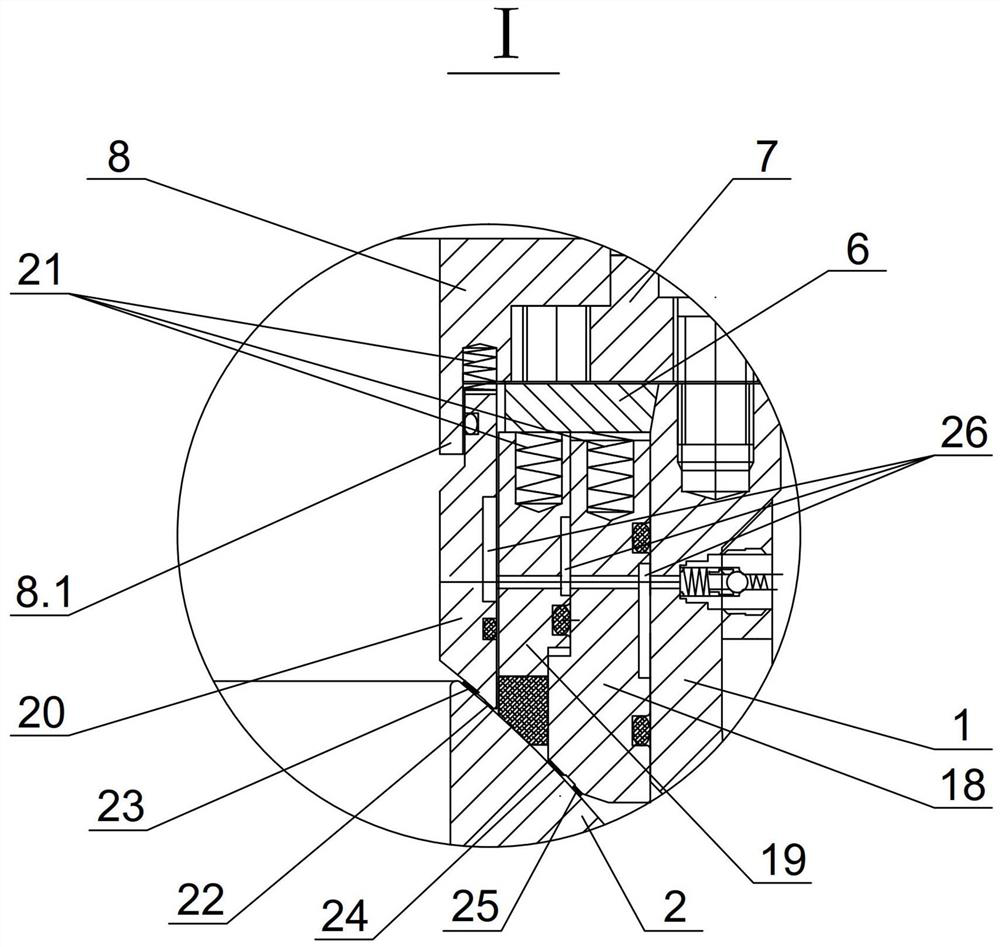

[0013] Such as figure 1 The automatic decoking multi-layer sealed unloading ball valve with double scrapers shown includes valve body 1, valve seat, ball 2, valve stem 12, transmission mechanism 13, seals and mounting parts. The valve seat adopts a single valve seat structure, Installed in the inlet channel 9 of the valve body 1, one end of the valve stem 12 is connected to the ball 2, and the other end is connected to the transmission mechanism 13, and the transmission mechanism 13 drives the ball 2 to rotate through the valve stem 12 to realize the opening and closing operation of the valve, and the outlet of the valve body 1 There is a gap between the inner wall of the valve chamber 16 on the side and the ball 2. When used in a discharge valve, the valve body 1 is installed vertically below the silo or storage tank through the inlet passage 9, and the material in the valve chamber 16 passes through the ball 2 and the valve chamber. The gap between the inner walls of 16 is d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap