Pipe ramming construction method and equipment thereof

A technology of construction equipment and construction methods, applied in mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve the problems of steel casing line deviation, difficulty in ensuring accuracy, and affecting construction quality, etc., to achieve Improve work efficiency and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

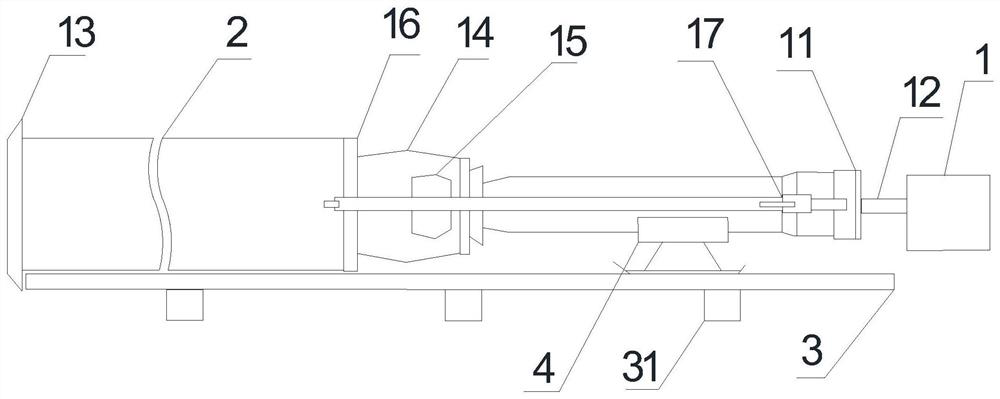

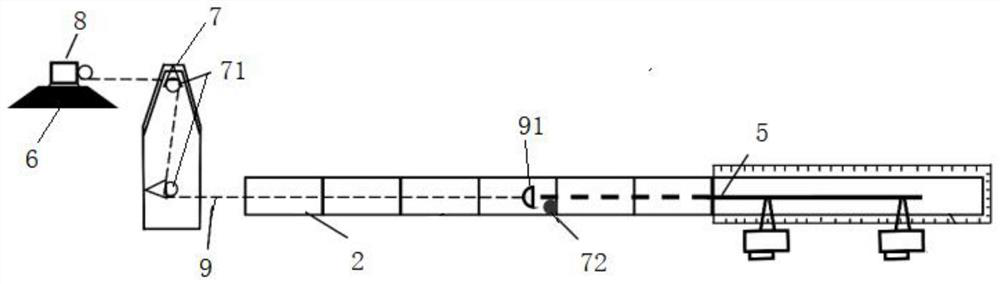

[0024] Such as figure 1 Shown is the construction schematic diagram of rammer pipe in the present invention.

[0025] Pipe rammer construction equipment, including: pipe rammer 1, guide rail 3, height adjustment device 4.

[0026] The pipe rammer 1 is used to advance the steel casing 2. Its structure includes: a pipe rammer 11, a connecting rod 12 and power equipment. The rear end of the connecting rod 12 is connected to the power equipment, and the front end transmits the impact force to the pipe rammer 11. The pipe rammer 11 pushes the steel sleeve 2 to advance, so that the steel sleeve 2 cuts the soil layer. After a plurality of steel sleeves 2 are welded and pass through the soil layer in turn, they pass through the pipeline in the steel sleeve 2 to complete the pipeline crossing construction.

[0027] In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com