Aggregate heat exchange system and method

A heat exchange system and aggregate technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of energy loss, cooling water temperature cannot be lower than 0 ℃, etc., to achieve increased contact area, efficient heating, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

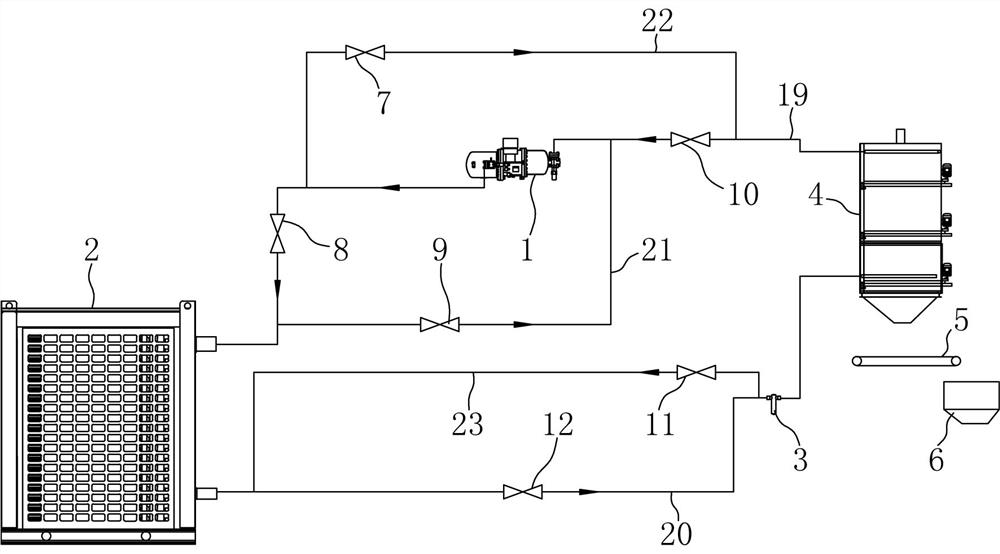

[0056] An aggregate heat exchange system, comprising an aggregate heat exchange device 4, the aggregate heat exchange device 4 is connected to a first main pipe 19 and a second main pipe 20 at positions close to the upper and lower ends respectively, the first main pipe 19 and the second main pipeline 20 are all connected to the air-cooled condenser 2;

[0057] The first main pipeline 19 is provided with a compressor 1, the first main pipeline 19 between the compressor 1 and the air-cooled condenser 2 is provided with a second stop valve 8, and the compressor 1 and the aggregate heat exchange device 4 is provided with a fourth cut-off valve 10 on the first main pipe 19;

[0058] The second main pipeline 20 is provided with a thermal expansion valve 3 , and the second main pipeline 20 between the thermal expansion valve 3 and the air-cooled condenser 2 is provided with a sixth shut-off valve 12 .

[0059] In a preferred solution, the first main pipeline 19 is connected in para...

Embodiment 2

[0065] On the basis of Embodiment 1, the specific structure of the aggregate heat exchange device 4 is as follows:

[0066] The top of the aggregate heat exchange device 4 is provided with an inlet for aggregate input, the bottom of the aggregate heat exchange device 4 is provided with an outlet for aggregate output, and the bottom of the aggregate heat exchange device 4 is provided with a conveyor belt 5 for conveying A buffer bin 6 is provided below the output end of the material belt 5 .

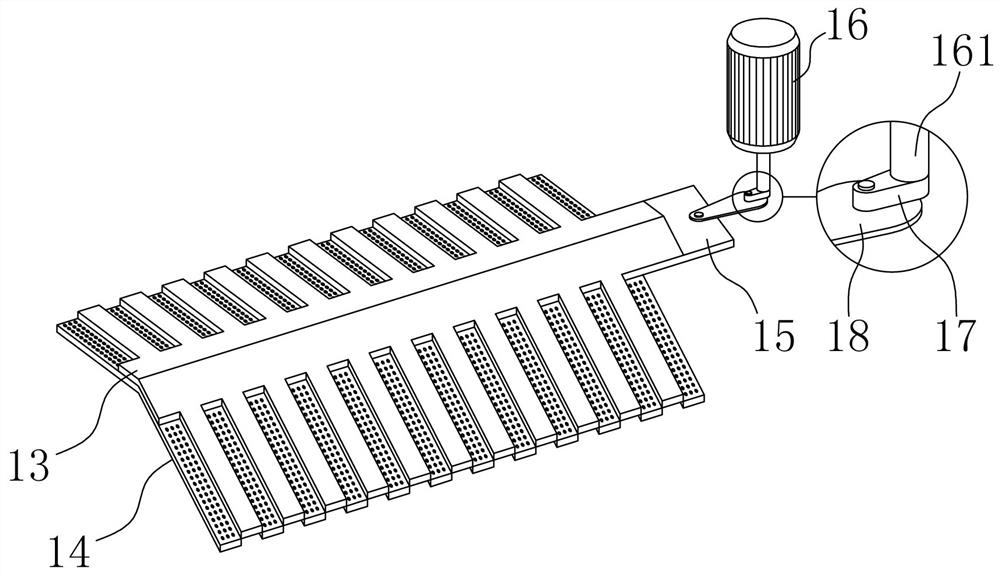

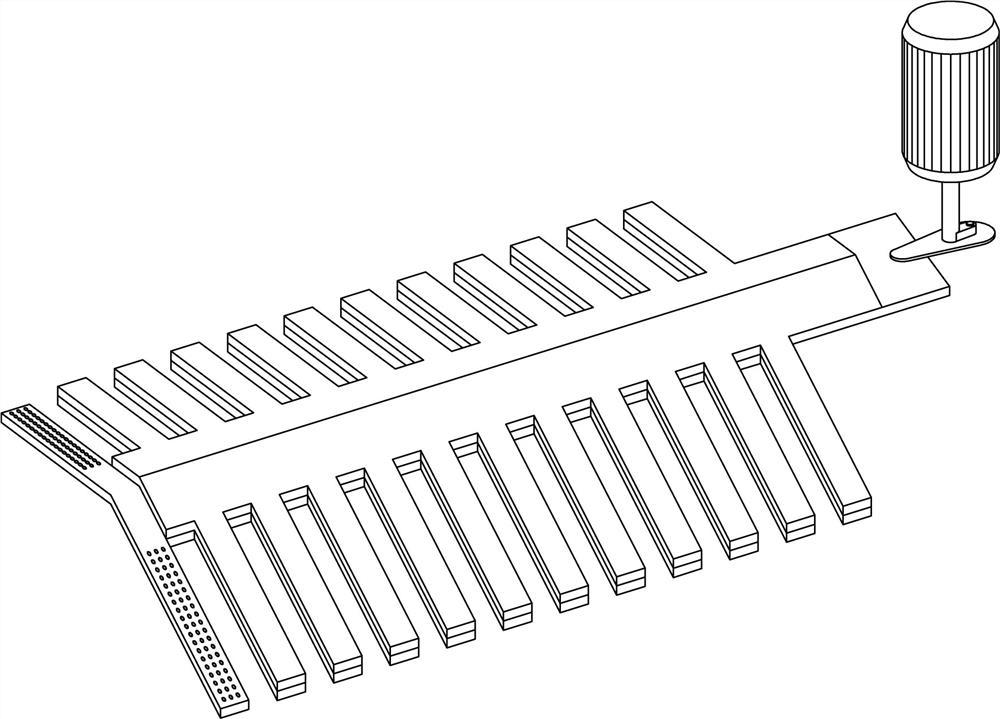

[0067] In a preferred solution, the aggregate heat exchange device 4 is provided with a plurality of horizontal separation mechanisms;

[0068] The single separation mechanism includes a fixed partition 14 fixed in the aggregate heat exchange device 4, a movable partition 13 is arranged above the fixed partition 14, and an extension plate 15 is arranged at one end of the movable partition 13, and the extension plate 15 is formed by The hole opened on the side wall of the aggregate heat e...

Embodiment 3

[0072] On the basis of embodiment 2, the concrete structure of separation mechanism is as follows:

[0073] Including the movable partition 13 and the fixed partition 14, the movable partition 13 and the fixed partition 14 are both "V" shaped plates, the obtuse angles of the movable partition 13 and the fixed partition 14 are set downwards, and the fixed partition The board 14 is provided with a plurality of ventilation holes 142 .

[0074] In a preferred solution, a first gap 131 and a second gap 141 are respectively provided on both sides of the movable partition 13 and the fixed partition 14, and the first gap 131 and the second gap 141 are connected between the movable partition 13 and the fixed partition. The two side parts of 14 form a plurality of strip parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com