Industrial steam terminal consumption prediction model establishment and prediction method and system

A technique for forecasting models and establishing methods, which is applied in forecasting, biological neural network models, energy industry, etc., and can solve problems such as low precision of forecasting methods, and achieve the effects of avoiding insufficient steam supply, untimely feedback, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

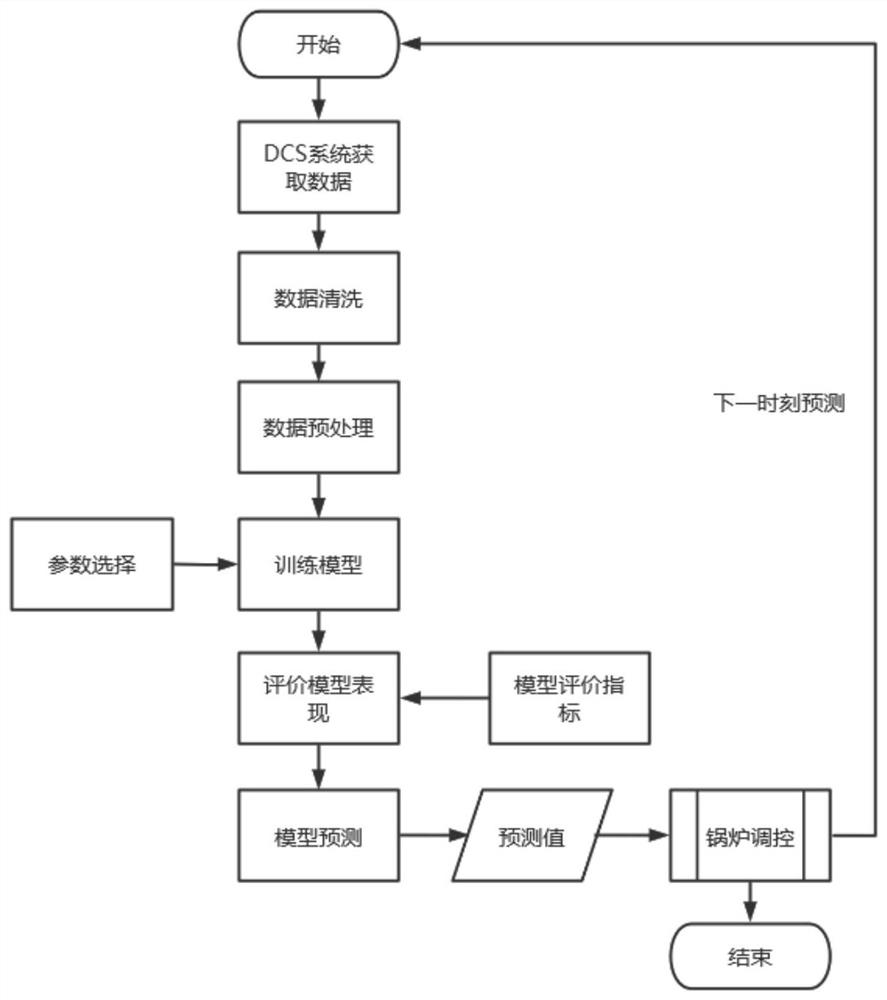

[0047] This embodiment discloses a method for establishing a prediction model for end consumption of industrial steam, the method comprising the following steps:

[0048] Step 1, making a sample data set: collect steam consumption data in units of hours to obtain hour-level data sequences; the steam consumption data in this step is historical steam consumption data collected systematically.

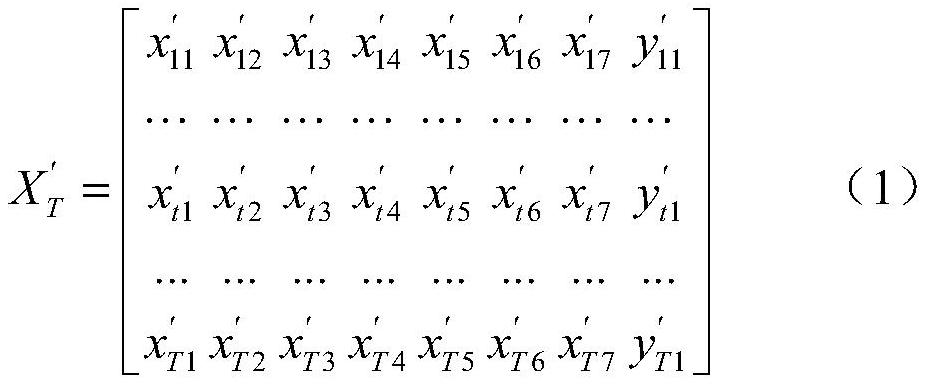

[0049] In this example, the historical steam consumption data of a thermal power plant in Xianyang is collected. The steam consumption end of the thermal power plant includes 7 enterprises, and the steam consumption from April 1 to May 30, 2019 is extracted from the database of the monitoring system The data form an hour-level historical steam consumption data sequence, with a total of 1349 historical data.

[0050] Step 2, data preprocessing: If there is missing data in the data, the missing values need to be filled, and then the abnormal values of the overall data after filling the ...

Embodiment 2

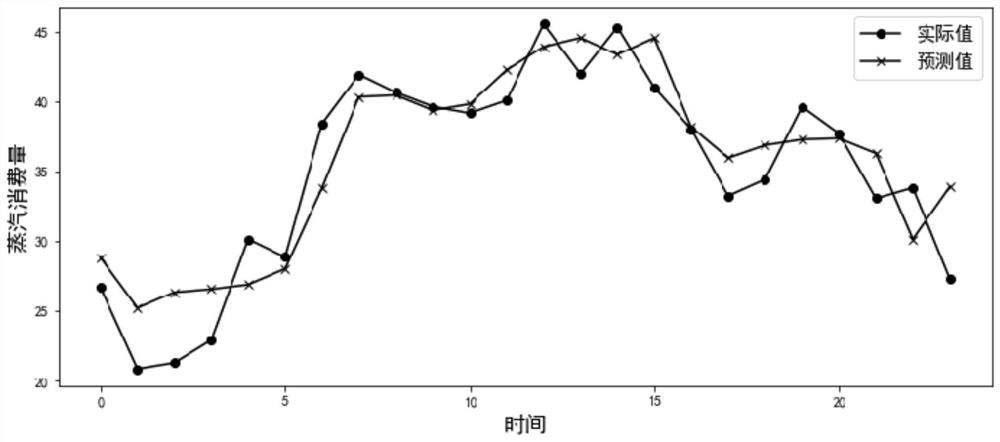

[0080] This embodiment discloses a method for predicting the final consumption of industrial steam. The model obtained in Embodiment 1 is used to predict the steam consumption at a certain time in the future. According to the data set L, the input end of the prediction model needs to know The steam consumption of one day, so the method of the present invention can predict the steam consumption of the next day. The prediction method in this embodiment is specifically:

[0081] Step 1, the data in this embodiment are 165 pieces of data in the test set of embodiment 1. Collect data according to the method of step 1 to step 2 in embodiment 1 and carry out abnormal value and missing value processing to data; Calculate {o t ' 1 ,o' t2 ,o' t3 ,o t ' 4 ,o t ' 5 ,o' t6 ,o' t7 ,x' t1 ,x' t2 ,x' t3 ,xt ' 4 ,x' t5 ,x t ' 6 ,x' t7} these data values.

[0082] Step 2: Input the data obtained in Step 1 into the prediction model obtained in Embodiment 1 after one-hot encodi...

Embodiment 3

[0085] This embodiment discloses a system for establishing a prediction model of end consumption of industrial steam, including a data acquisition module, a data preprocessing module, a data calculation module and a model training module.

[0086] Among them, the data acquisition module is used to collect steam consumption data in units of hours to obtain the data sequence, and the DCS system of the boiler in actual production will save the steam consumption in real time; the data preprocessing module is used to convert abnormal values in the data sequence Set to the missing value NaN, and fill the missing value in the data sequence; see the detailed record of step 2 of embodiment 1 for the specific filling and removal process; the data calculation module is used to calculate the difference between the steam consumption at adjacent moments, as in step 3 The difference between steam consumption at time t-1 and steam consumption at time t-2, and the position of time t in one da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com