Pre-terminating connector for copper cable

A connector and pre-termination technology, which is applied in the direction of connection, conductive connection, and parts of connection devices, can solve the problems of adding copper cable pre-termination connectors and data copper cables to resist side tension and torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

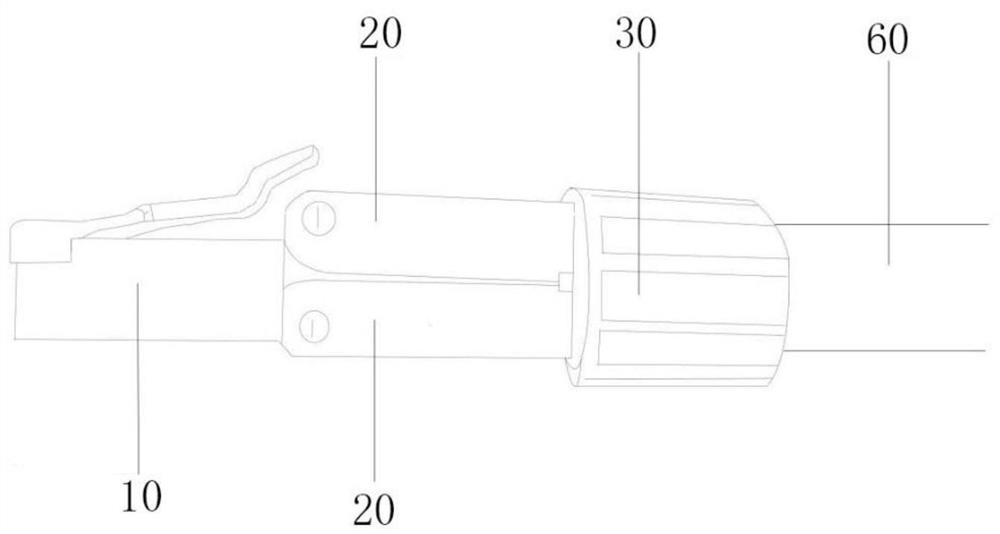

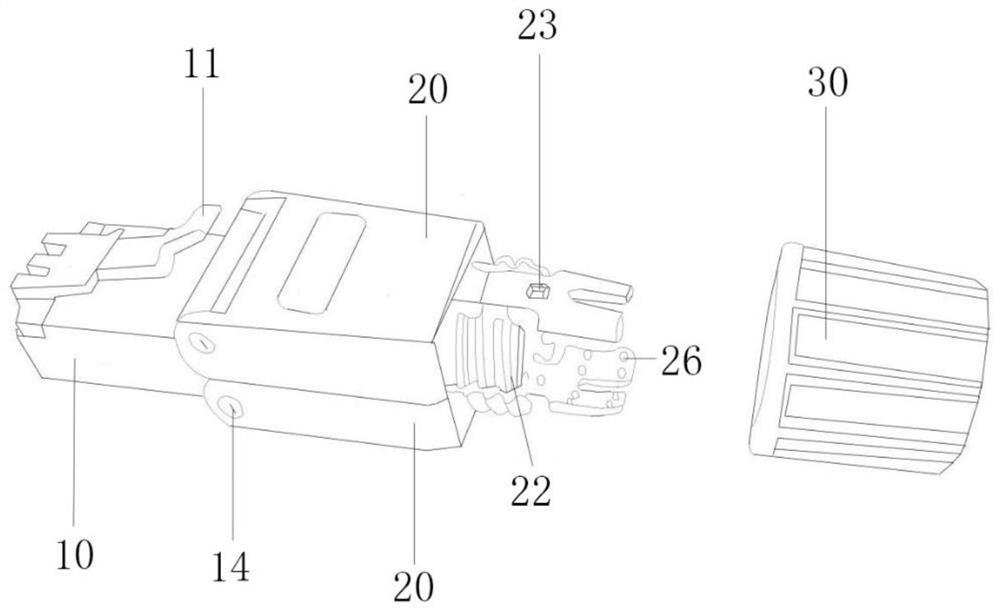

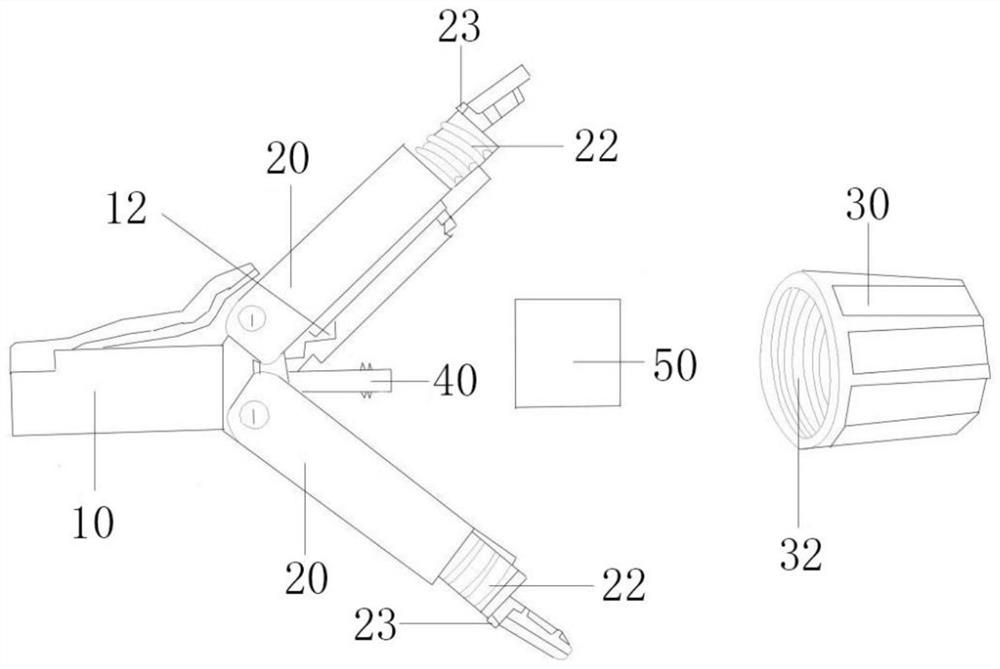

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] This embodiment discloses a copper cable pre-terminated connector, its structure is as follows Figure 1 to Figure 7 As shown, the cable entry structure through the rear end of the connector is used as Figure 8 As shown, the casing 20 is opened through the horizontal connection shaft 14 in the figure as the axis center, and after opening, it is shown as Figure 4 As shown, the card firmware 50 is removed, and the three parts of the connector that can be detached are shown as follows: image 3 As shown, in order to ensure the stability of the finished connector, except for the above three parts, other modules do not support secondary assembly.

[0040] After cutting according to the required length of the pre-terminated data copper cable 60, one or both ends of the data copper cable 60 pass through the tail of the lock sleeve 30, and the passing distance is not too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com