Method and equipment for removing local moisture of boxed tobacco strips

A technology of sheet tobacco and box packing, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of lowering the grade of tobacco leaves, lowering toughness and elasticity, dark appearance and other problems, and achieves the effect of rapid dehydration treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

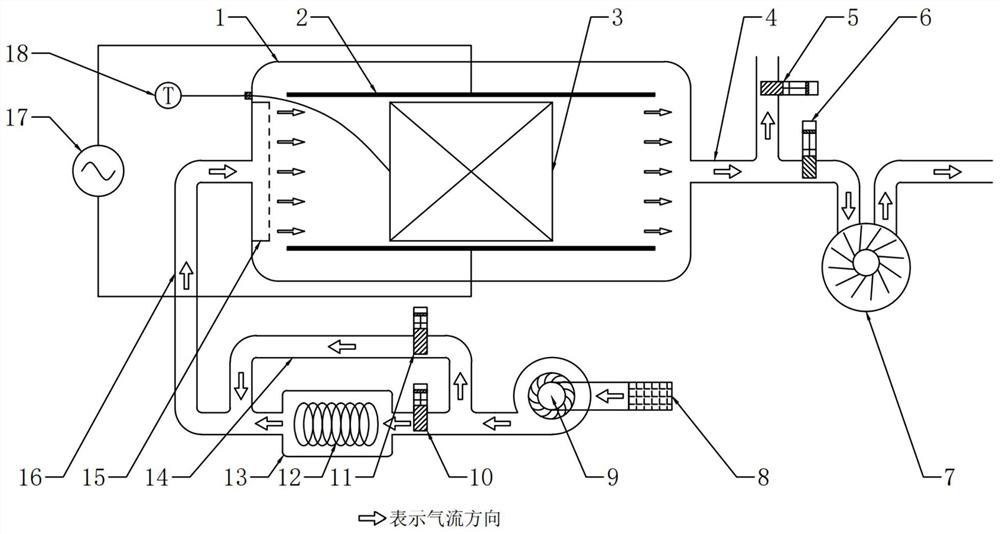

[0037] One of the cores of the present invention is to provide a local moisture removal method for box-packed tobacco, so as to realize selective dehydration and anti-mildew treatment on the damp parts of box-packed tobacco, and at the same time avoid or reduce the adverse effects on non-moistened cigarettes in the box .

[0038] Another core of the present invention is to provide a local moisture removal device for box-packed lamina, so as to implement the above-mentioned local moisture removal method for box-packed lamina through the device.

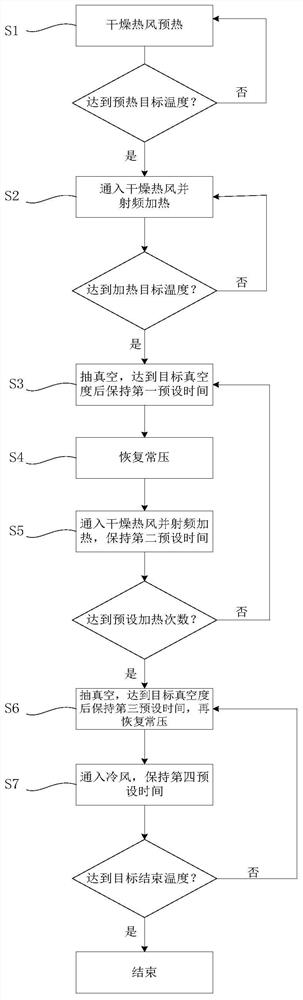

[0039] Please refer first figure 1 , in the local moisture removal method of box-packed tobacco disclosed in the present invention, comprise the following steps:

[0040] S1) dry hot air preheating;

[0041] Specifically, put the box-packed cigarettes into a cavity that can be heated by radio frequency. The cavity has an air inlet and an air outlet. Preheat the box-packed lamina, and judge whether the temperature of the damp area of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com