Liquid ethylenediamine recovery pretreatment equipment and pretreatment recovery method thereof

A technology for recycling and processing ethylenediamine, applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical/physical-chemical stationary reactors, etc. , the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

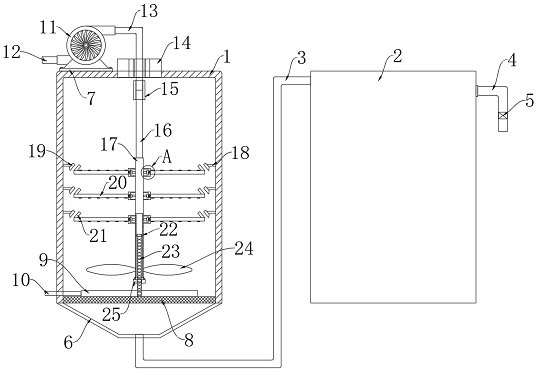

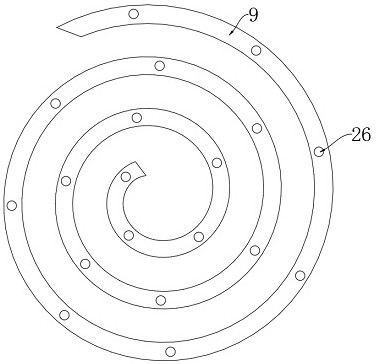

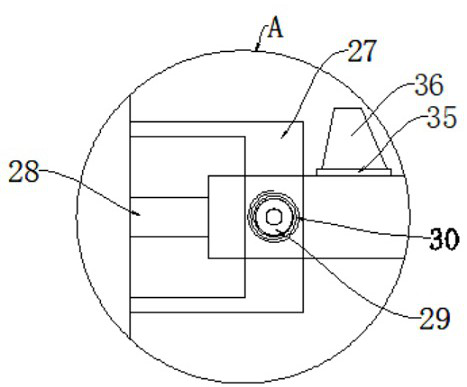

[0036] refer to Figure 1-4, a liquid ethylenediamine recovery pretreatment equipment, including a mixing reaction box 1 and a recovery treatment equipment 2, the bottom of the mixing reaction box 1 is equipped with a funnel cover 6, the funnel cover 6 is connected to the recovery treatment equipment 2 through a delivery pipe 3, A corresponding pump body can be installed on the conveying pipe 3 to realize the pumping of reactants; a recovery pipe 4 is installed on the recovery processing equipment 2, and an electromagnetic valve 5 is installed on the recovery pipe 4, and the upper end of the mixing reaction box 1 runs through and is fixedly connected with a fixed valve. Block 14, and the upper end of mixing reaction box 1 is equipped with negative pressure blower 11, and the bottom of negative pressure blower 11 is equipped with mounting plate 7, and mounting plate 7 is connected with mixing reaction box 1 by bolt; A first feed pipe 12 is installed, and an air outlet pipe 13 i...

Embodiment 2

[0054] A kind of liquid ethylenediamine reclaims pretreatment equipment, and embodiment 1 is similar, and difference is,

[0055] Both the nozzle hole 35 and the through hole 26 are provided with an adjustable nozzle 36, such as Figure 5-Figure 6 As shown, the adjustable nozzle 36 is composed of a nozzle 37 and a nozzle 38. The nozzle 38 is composed of a rotating ball 381, a different diameter connecting pipe 382 and a plugging nozzle 383. The rotating ball 381 is flexibly connected to the different diameter connecting pipe 382 and the nozzle 37. In between, the end of the plugging nozzle 383 is closed, and the circumference of the plugging nozzle 383 is provided with a plurality of nozzle holes 384, and the inner diameter of the nozzle holes 384 gradually increases from the inside to the outside. Under the action of the rotating ball 381, the different-diameter connecting pipe 382 can drive the nozzle, so as to realize the adjustable angle of 0-60 degrees along the axial dir...

Embodiment 3

[0058] A kind of liquid ethylenediamine reclaims pretreatment equipment, and embodiment 1 is similar, and difference is,

[0059] The rotating ball 381 has a spherical shell structure, and the different-diameter connecting pipe 382 connects the rotating ball 381 and the nozzle 38, and the outer diameter gradually decreases from one end close to the rotating ball 381 to the other end, so as to locally accelerate the flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com