Cabinet hanger sorting and settling method for ship process

A process and hoisting technology, applied in the direction of load hanging components, track systems, conveyors, etc., can solve the problems of high employee complaint rate and poor actual effect, and achieve the goal of reducing labor intensity, improving production efficiency and changing the production environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

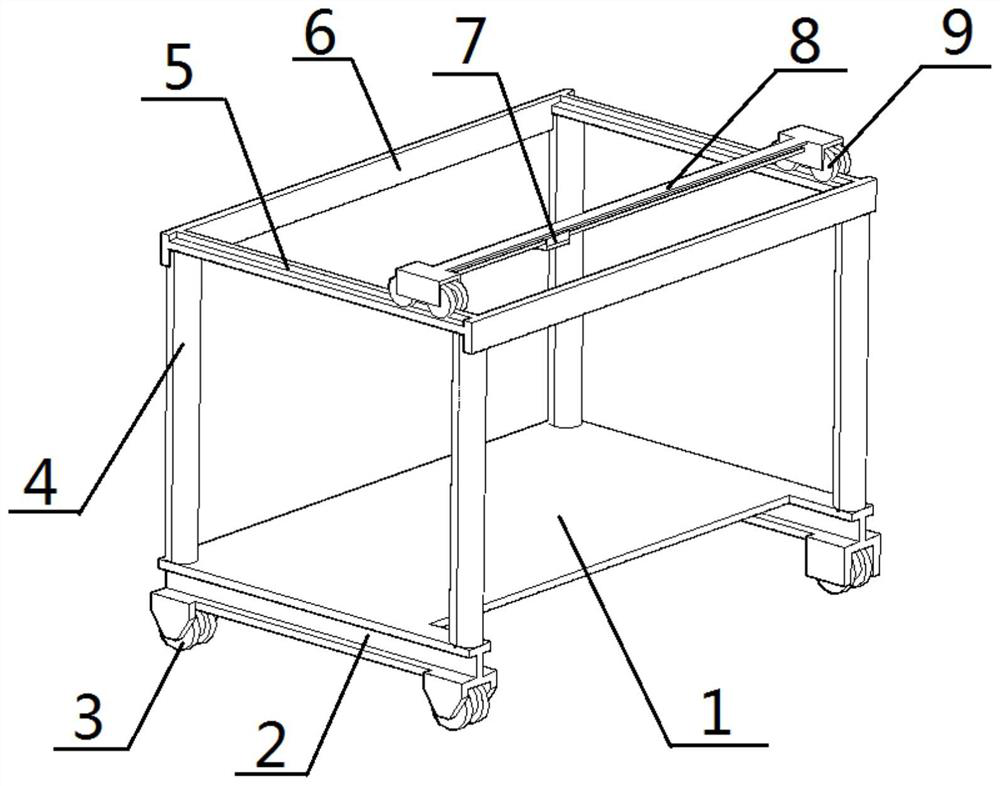

[0025] This embodiment provides a sorting and sorting device for ship craft hanging codes, which mainly includes a material sorting trolley and a material sorting track 10 structurally. The material sorting trolley moves back and forth on the material sorting track 10, completes the material sorting work by changing the position, so as to be used in a limited material sorting site, and sorts and arranges the process hanging codes of the material sorting site.

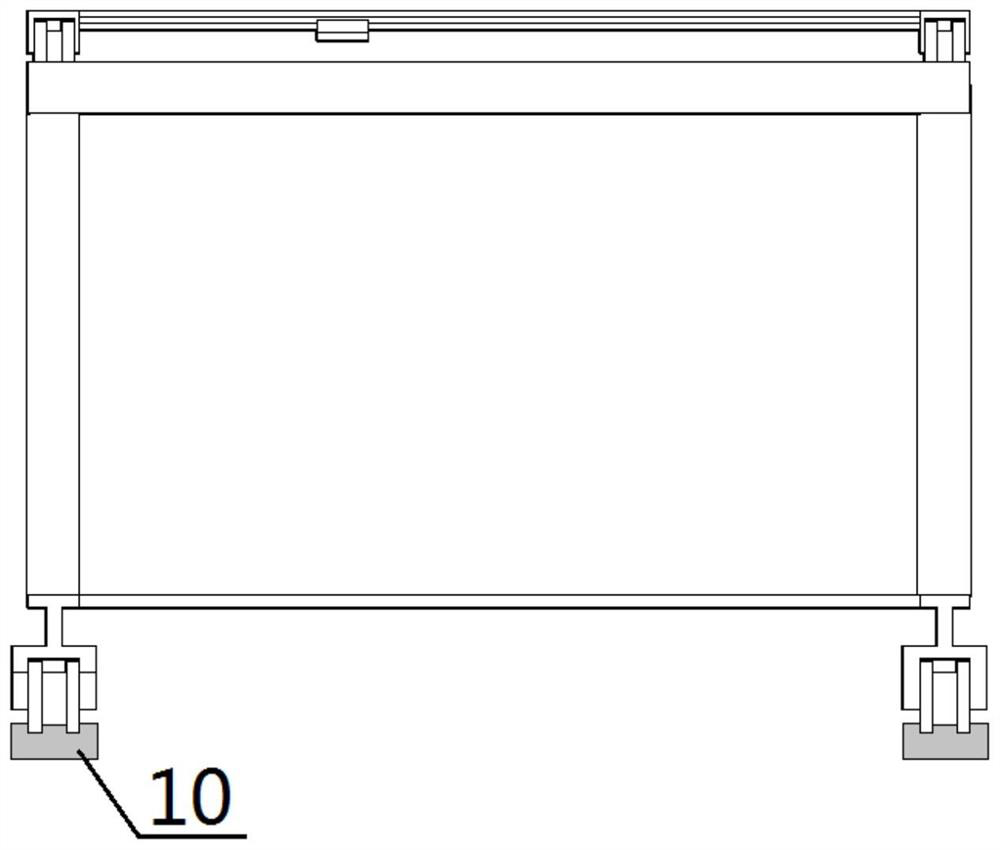

[0026] The material management track 10 is two mutually parallel square steels laid along the material management station of the process hanging code.

[0027] The material handling trolley includes a trolley body, a platform plate 1, a top beam 8 and an electric hoist 7, and the trolley body includes a platform plate 1, a support column 4, a top rail 5, H-shaped steel 2, bottom rollers 3 and an anti-fall baffle 6. The bottom roller 3 is set up on the material track 10, and the bottom roller 3 shafts are installed on th...

Embodiment 2

[0033] This embodiment provides a sorting and sorting method for ship craft hanging codes, which includes the following steps:

[0034] Step 1. Place the bottom roller 3 on the material sorting track 10, and push the material sorting trolley along the material sorting track 10 to the process material code sorting area. When the material sorting trolley moves on the material sorting track 10, the hanging object gap is located One side of the moving direction of the sorting trolley.

[0035] Step 2. Adjust the position of the electric hoist 7 on the top beam 8 to ensure that the electric hoist 7 is located directly above the target process hanging code;

[0036] Step 3: Start the electric hoist 7 and put down the lock hook, fix the lock hook with the center hole of the process hanging code, start the electric hoist 7 again to lift the process hanging code to a certain height, move the top beam 8, release the lock hook and lift the process hanger The code is placed on the platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com